-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

- Home

- Forums

- Buy and Sell, Deals Spotted, and Help Required

- Request a part, job, or quote from members

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need Some 8" Round Stock Cut - Calgary

- Thread starter YYCHM

- Start date

historicalarms

Ultra Member

get a big cardboard box. cut one side out for access and the 3 remaining side "sort of control" the scarf ricochet.

get a big cardboard box. cut one side out for access and the 3 remaining side "sort of control" the scarf ricochet.

I grabbed a big welding magnet and a piece of sheet metal roughly 12"x12" and use that as a movable shield stuck to the table.

Brent H

Ultra Member

Hey Craig,

there is also a relief in the middle of the block that retains oil and ensures good face contact. I posted the block I made here: https://canadianhobbymetalworkers.c...-a-10-ld-utilathe-standard-modern.1475/page-5

there is also a relief in the middle of the block that retains oil and ensures good face contact. I posted the block I made here: https://canadianhobbymetalworkers.c...-a-10-ld-utilathe-standard-modern.1475/page-5

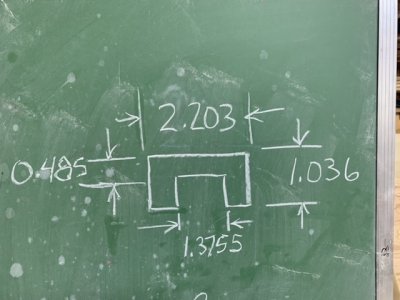

I can measure it up tomorrow with the corresponding dimension of the bar it rides on. I screwed up the bolt hole /

It is 0.050” off centre due to not compensating for the edge finder - ugh! Works fine though.

Should be the same size as my bar. Yours came from a 9" Utilathe. Just curios as neither looks like the image in the manual, which looks to be a casting with machined surfaces.

RobinHood

Ultra Member

IIRC, the bar was ground. So if they cast the slider block and machine the U-shape to 1 3/16”(1.1875) and take nominal cold rolled 1 3/16” bar (which would measure a bit oversize) and surface grind the bar, they could end up with a bar width of 1.186” for a nice sliding fit in the block.

Brent H

Ultra Member

Hi Craig, following your thread with lots of interest nice work however, somewhere along the way I missed out on what your project is.

From your latest photos I assume you're making a taper turning attachment for you lathe so you can reproduce tapers?

Thanks for hitting the like button, appreciate that.

From your latest photos I assume you're making a taper turning attachment for you lathe so you can reproduce tapers?

Thanks for hitting the like button, appreciate that.