Hi Craig, following your thread with lots of interest nice work however, somewhere along the way I missed out on what your project is.

From your latest photos I assume you're making a taper turning attachment for you lathe so you can reproduce tapers?

Thanks for hitting the like button, appreciate that.

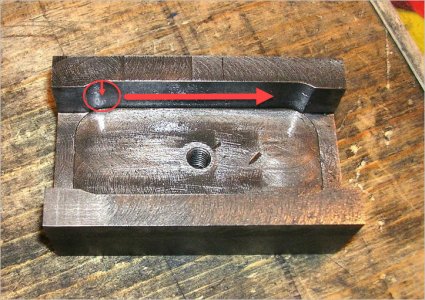

Ya, this thread kind of morphed into a project thread. You are correct, it's an improved (better tolerance) shoe for the taper attachment on my lathe. I never received the original with the lathe when I bought it.