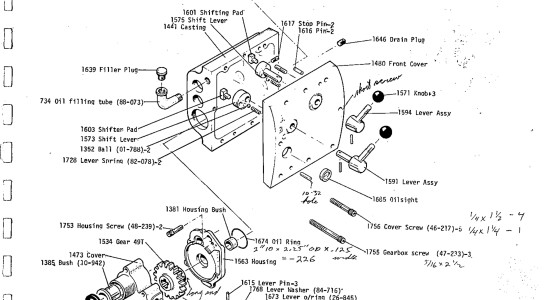

No, it is imperial. Both cross and compound lead screws are 10 tpi but the cross is 2-start, so one rotation is 1/5 of an inch, or 200 thou. That explains the marks on the dials -- graduations in thou on both, and radius, not diameter (for Sasquatch, I totally agree).I'm pretty sure the lathe is metric threaded but I'm getting numbers that don't make sense to me.

I haven't much experience with trapezoidal metric threads but the metric measurement just don't look precise enough.

I used my most accurate digital calipers for the measurements, what do you guys think?

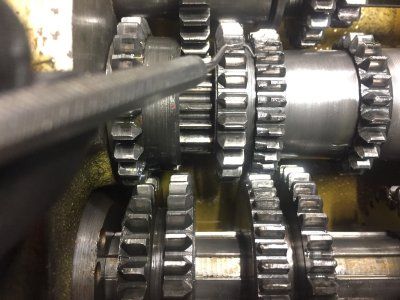

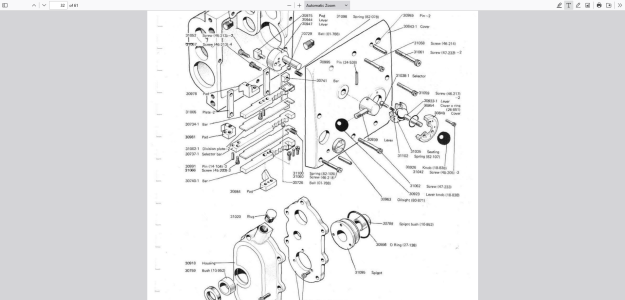

I THINK all the Bantams have power feed driven separately from the lead screw. Chipmaster does. You can see the feed data in the red boxes on the gearbox chart. When those gears are engaged, both the lead screw and the feed screw are driven, but unless you are cutting threads you are best to disengage the lead screw clutch just outside the gearbox to reduce wear on the thrust bearings. The note '1/2' just showing in your second picture advises that cross feed goes at 1/2 the speed of the longitudinal feed, which is stated in the appropriate box.

I also THINK the Bantam can only power feed toward the headstock and toward centre on the cross. Chipmaster can be reversed, which is kind of handy for threading away from the chuck (for example, managing a tight shoulder thread termination) though there are other ways to do that.