I joined the Forum because I wanted to get a mill. Didn’t need a mill but I thought it would be fun. It took many months, but with a lot of help (from the Forum) I eventually came home with a (1000 lb bench top) RF45 clone that I bought from Modern Tool. I’m very happy with that purchase.

After a while I started to think that the mill looked lonely and it needed a lathe to keep it company.

Back to the Forum for advise. Many thanks!

So I zeroed in on getting a 10x22 to a 12x28 - that size should do everything I want and fit into my tight work space. (Please keep in mind that I have never owned a lathe.) Top contenders were either a used North American built machine or doing a trip to Precision Matthews and trailering home one of their offerings.

At the Ontario Meetup I meet Stuart Samuel. We were talking about milling toe clamps and he mentioned that he was getting a new (used 16x40 Taiwan) lathe. I asked what lathe was it replacing and one thing lead to another. A few days ago his 1972 vintage Myford Super 7 was loaded into my trailer.

Can you see the tear in his eye as he waves goodbye?

It made it home safe and sound (below picture). Note that the motor had been remove and strapped to the stand. This made the lathe light enough that Stuart and I could man handle it into the trailer (yes it is a small lathe).

Here’s a pic using my little Kubota to get it slid back onto the stand:

I gave it a thorough cleaning and check over. To my untrained eye, it appears to be in good condition with little measurable wear or any damage from abuse.

Here’s the front and side views:

Yes this (7x19) is a lot smaller than the 10x22 I had arbitrarily set my sights on.

But WOW - double WOW - it has character.

- Made in England.

- Myford has a big following to call on for advice.

- Extremely capable for its compact size / it is punching way over its weight class.

- Parts and accessories are relatively easy to find and don’t need modifications to fit. (Try that with a 52 year old Chinese lathe)

- 14 spindle speeds (32 to 2500 rpm evenly spaced) enabled by an easy to engage back gear.

- No electronics. Just a simple on/off switch.

- Easy to use clutch. Love it!

- QCGB. Nice. Very nice.

- Belt changes are quick, easy and simple.

- It’s not JD green.

Here’s pics of the QCGB, and the spindle and carriage:

Here’s a pic of the back side.

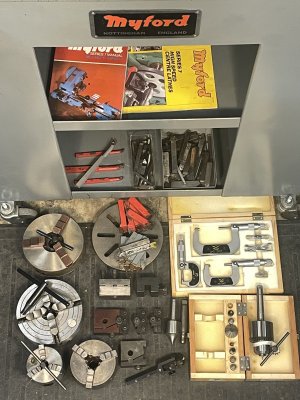

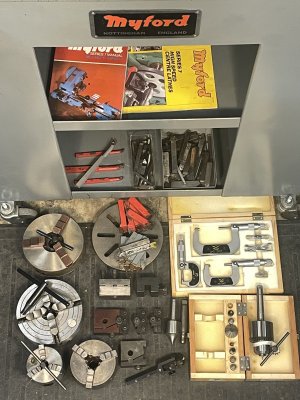

Here’s the accessories it came with (sitting on the floor in front of the Myford stand):

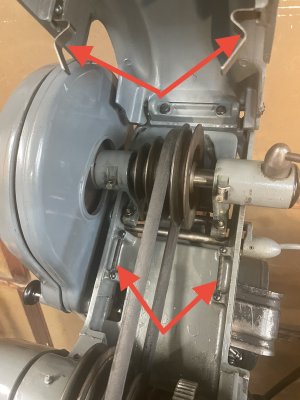

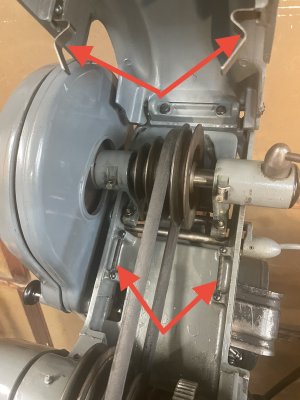

A design thing I like, (in pic below) the clips on the cover engage these spring when the cover is closed. Secure and no rattling!

Here’s another design thing i really like (pic below) you can use your left hand on the QCGB lever while your right hand (on the lead screw wheel) can easily rotate the gears to make engagement simple. BTW - this wheel is indexed so that you can accurately control horizontal movement.

Love using pictures to make things so easy to explain - as an aside - this Forum supports and allows us to attach pictures so easily- special thanks to J.

Next pic is the change gears. I don’t have metric gears but they are available - note the decal on the door shows gear selection for metric pitches

I’ve not made any chips yet.

Still getting acquainted.

After a while I started to think that the mill looked lonely and it needed a lathe to keep it company.

Back to the Forum for advise. Many thanks!

So I zeroed in on getting a 10x22 to a 12x28 - that size should do everything I want and fit into my tight work space. (Please keep in mind that I have never owned a lathe.) Top contenders were either a used North American built machine or doing a trip to Precision Matthews and trailering home one of their offerings.

At the Ontario Meetup I meet Stuart Samuel. We were talking about milling toe clamps and he mentioned that he was getting a new (used 16x40 Taiwan) lathe. I asked what lathe was it replacing and one thing lead to another. A few days ago his 1972 vintage Myford Super 7 was loaded into my trailer.

Can you see the tear in his eye as he waves goodbye?

It made it home safe and sound (below picture). Note that the motor had been remove and strapped to the stand. This made the lathe light enough that Stuart and I could man handle it into the trailer (yes it is a small lathe).

Here’s a pic using my little Kubota to get it slid back onto the stand:

I gave it a thorough cleaning and check over. To my untrained eye, it appears to be in good condition with little measurable wear or any damage from abuse.

Here’s the front and side views:

Yes this (7x19) is a lot smaller than the 10x22 I had arbitrarily set my sights on.

But WOW - double WOW - it has character.

- Made in England.

- Myford has a big following to call on for advice.

- Extremely capable for its compact size / it is punching way over its weight class.

- Parts and accessories are relatively easy to find and don’t need modifications to fit. (Try that with a 52 year old Chinese lathe)

- 14 spindle speeds (32 to 2500 rpm evenly spaced) enabled by an easy to engage back gear.

- No electronics. Just a simple on/off switch.

- Easy to use clutch. Love it!

- QCGB. Nice. Very nice.

- Belt changes are quick, easy and simple.

- It’s not JD green.

Here’s pics of the QCGB, and the spindle and carriage:

Here’s a pic of the back side.

Here’s the accessories it came with (sitting on the floor in front of the Myford stand):

A design thing I like, (in pic below) the clips on the cover engage these spring when the cover is closed. Secure and no rattling!

Here’s another design thing i really like (pic below) you can use your left hand on the QCGB lever while your right hand (on the lead screw wheel) can easily rotate the gears to make engagement simple. BTW - this wheel is indexed so that you can accurately control horizontal movement.

Love using pictures to make things so easy to explain - as an aside - this Forum supports and allows us to attach pictures so easily- special thanks to J.

Next pic is the change gears. I don’t have metric gears but they are available - note the decal on the door shows gear selection for metric pitches

I’ve not made any chips yet.

Still getting acquainted.