gerritv

Gerrit

McGyver's is not a beginner one, have to make or source gears for his Plan B style. The Plan A style in his article is quite attainable with a milling machine, a lathe and some care. And sharp edged wheels, best to get ones specifically for cut knurling.I copied @McGiver on my note because he is the author of the article you referred to. I copied @gerritv because he has made a simpler knurler. I'm interested in their opinion of how easy it would be for a beginner to make one. I don't think it's a, slam dunk at all but those two guys are infinitely better qualified to assess that than I am.

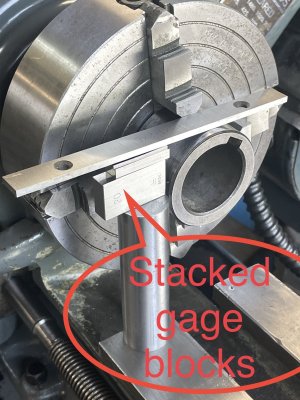

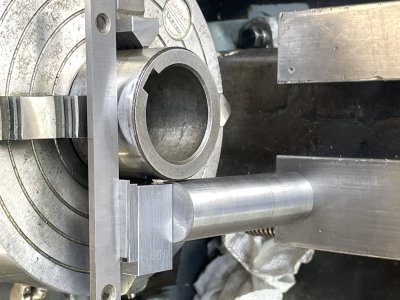

My design is simpler, requires a real cut knurling wheel, but is really only suited to coining/straight knurls. I also chose to buy the bushing etc, which added to the cost ($98 total I think).

Arbutus also made one afaik, his could do coining as well as 60degree knurls.

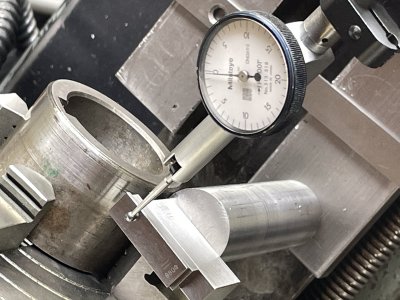

All of the above need at minimum air blast, preferably with some liquid spitting, to clear chips. You should be doing this with pressure knurling as well of course.

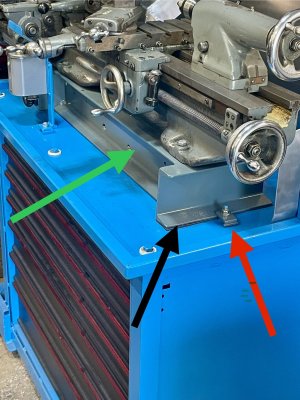

Using mine on a Sherline wasn't a great experience, but works great on the King KC1022.