I think you didn't mean to say that. Taking umbrage means that you feel upset or annoyed

because you feel that someone has been rude or shown no respect to you.

I don't think that is what you meant because there would be no reason for you to feel that way.

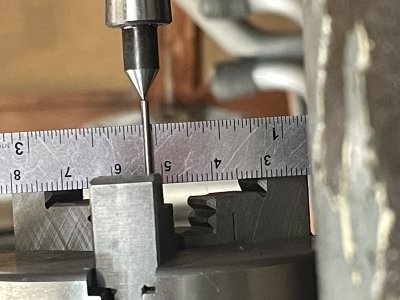

I disagree with this. I have no issues with using the ruler. It works quite well. But not ALWAYS. In the case of work that has not yet been turn concentric, the ruler will not work. The height standard will.

In the case of work that requires a high or low tool, the ruler does not always work well either. The height standard is much more useful and marginally faster.

Although I used a ruler for years, I cannot say how accurate the ruler will always be. I think it depends somewhat on the relative tool geometry. A tool with a nose that has a dominant slope could easily overpower the round stock tangent forces.

What I can say is that the standard can easily be used to sub thou levels of precision and be absolutely accurate. Why? Because it is independent of the work. It is a pure reflection of the tool height to lathe center geometry.

Perhaps there are those who couldn't use one as well as I do because they lack sensitivity in their fingers. But I have not yet met this person.

I understand and can easily do the math you referred to in an earlier post. I love math. Math is a wonderful tool. It's also easily abused just like statistics. When the math says it doesn't make much difference, I conclude that the mathematician is either a purist who doesn't understand the practical realities of his calculations or he is a manipulator who uses complicated math to prove a point - the same way so many statisticians do. The real answer to the math in this case is a little more along the lines of - it depends on the real question! The results depend on the diameter, the material, and the tool and therefore there is no one answer.

Our discussion has drifted a bit from a height gauge being a waste of time to being too specific machine dependant.

I can agree with you that they do get dedicated to one machine. If that is the sole criteria, then your point is taken.

However I have lots of tools that get dedicated to a particular machine. Perhaps the best example is Allen wrenches. I tend to buy extra sets specifically so I can take them apart and dedicate a given wrench to a given machine and I put them all in a wooden block that stays with each machine. If I don't do that, then I end up losing the key as it wanders from job to machine to machine. I don't have two lathes with QCTPosts, but if I did, each would have its own tool holders. I'll be damned if I'm gunna constantly be changing tool heights as I swapped tool holders from machine to machine. In this way, I would also have multiple height standards - one for each machine. And it wouldn't bother me one iota that I did. I would simply consider the height standard to be a part of the machine it goes with and each one would live with its respective machine.

Absolutely agreed. You do you Trev, and sadly, I'll do me!

This is the part that worries me. How do I know you used it properly? How do I know you made it properly?

Your conclusion is sooooo contrary to my experience. The first time I saw one used, I fell in love. Every guy I have ever shown one to also fell in love. That includes both hobbiests and pros.

You are the single and only outlier that I know. If I read

@Dabbler's post, his experience with others is similar. Yet you are very passionate about your feelings against it. So passionate that I can't help but feel we are debating two different things. Call it my intuition or call it my foolish unwillingness to give up on you.

You didn't want me to waste my time making a video for you. But please do me a favour and watch Joe Pies video on this. I didn't use his method to make mine, but his points on using it are bang on if not perhaps even understated. I'm not a fan of Joe Pie, he is bit too pedantic for my taste. But it would be very hard to argue about how skilled he is as a machinist.

Here is his video on making a standard.

If you don't want to watch him making one or his discussion about proper height setting, just fast forward to the use of the tool at 6:20.

To be honest, I like the way he made his better than the way I made mine, but both his and mine could be significantly improved by making the length of the standard adjustable. I've also seen standards that incorporated a magnet in the base. I dunno if I like the magnet though.

Joe focusses on the merits of being exactly on center. We both know that isn't always true. But for the purpose of describing the tool, how its made, and how it is used, his video is as good as any.

Hopefully you find some value in the video. Hopefully you can also see beyond Joe's focus and also see how easy it is to offset the tool high or low.

If not, I've truly tried my best. You do you and I'll keep bein the ugly hairy guy.....