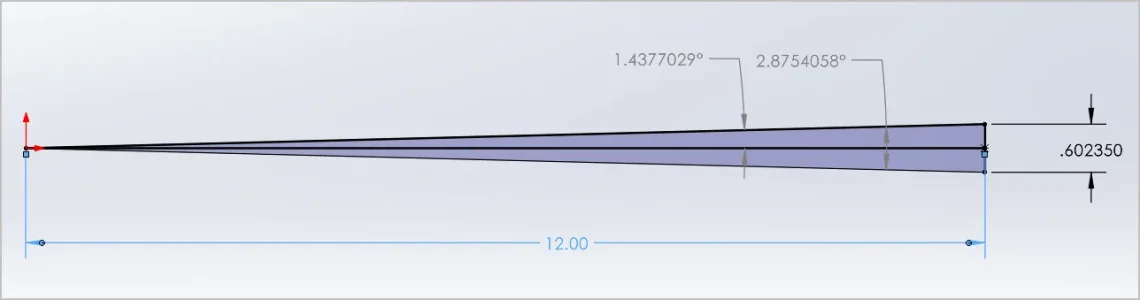

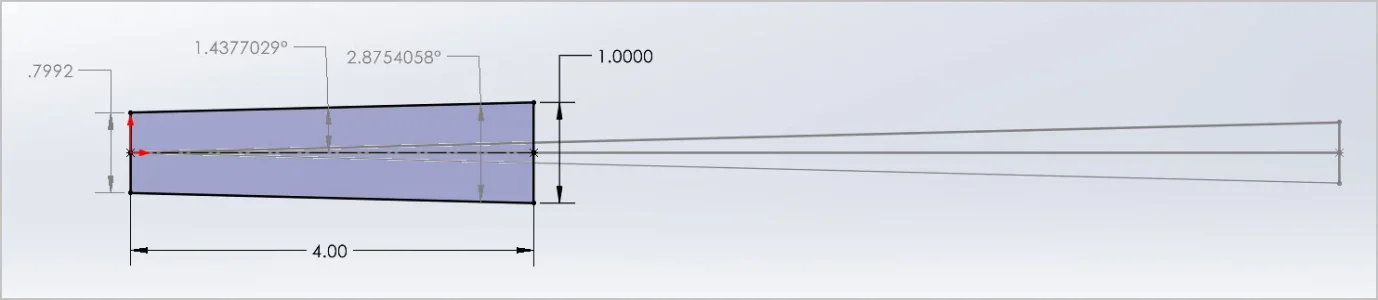

I believe that the original Morse taper as set by Mr Morse himself was not a measurement of the difference in diameter but rather was a specific angle of 2 degrees 50 minutes. I recall that this angle was chosen to arrive at a grade of 5%, but I can't make perfect sense of that just off hand.

By my math, a 5% grade actually has an angle of 2 degrees 51.6 minutes. Which is pretty darn close to the 2 degrees 50 minutes that I remember. Maybe it's "close enough???

I was also told that this angle was arrived at experimentally as optimum for good solid thrust retaining as well as ease of disassembly. Less angle would stay together well, but couldn't be disassembled easily. If so, then surely 51.6 degrees really is close enough to 50, so why keep an awkward number..... Though 5% is probably less awkward than 50 minutes.......

On reflection, I wonder if this small difference might be the variation that you have experienced

@PeterT ?

Other tapers with different angles (eg Jacobs) claim the same benefit though so.....

Recall, that Morse tapers were (and still are) primarily used for thrust applications (drill press, etc).

I think it's relevant to know that Morse was also the guy who invented twist drills and the original drills were made with Morse taper arbours.....

I suspect that the different angles you see everywhere are the result of the medical industry playing around with the numbers to achieve good bone interference fits for joint and bone osteoplasty which didn't work well using the original angles because of the dissimilar materials.

Coincidentally, I learned this latter fact from a bone prosthetic specialist I met in Edmonton. I stayed at his house while I judged a dog trial East of there. I accept what he told me.

In other words, there is no magic in the Morse Taper standard. It's kind of like the original foot or even the new meter (both just arbitrary numbers) one original based on the King's foot size and the other based on a specific arbitrary conversion of one inch = 2.54 cm.

Anyway, thats my old memetic version of the Morse Taper for whatever that is worth. It may or may not be correct.