A couple of notes.

-if you've incorporated a solid toolpost, there is no compound therefore you can't utilize it for tapers

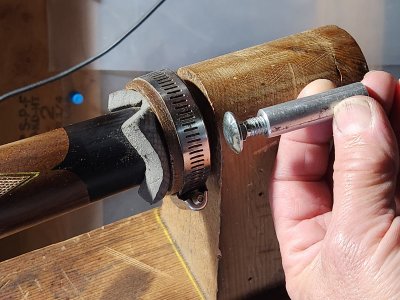

-you can still use the tail stock offset method to do tapers but if you have a long taper with a great angle, you might not be able to offset the tail stock enough

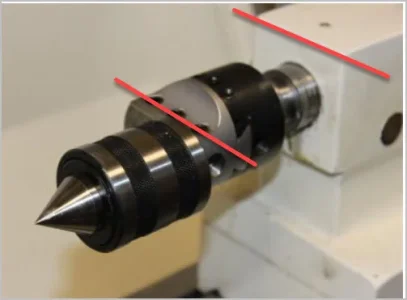

-you might also need to do a taper with a part between centers

-when using the compound for doing tapers longer than and inch or two, the inconsistant turning of the handle or stoping can transmit ridges into the work surface. If you're using the two hand approach to turn the compound handle, you can't squirt cutting fluid. (Yes, you can use a cordless drill to give yourself power feed, but on mine, the speed was too fast even on low, and controlling the speed was almost useless.)

I've used my homemade TTA to:

- do rifle and shotgun barrels

- make the abour adapter for balancing grinding wheels

- made several wooden spindle wipers for MT3, MT4, NMTB #40

-some other little projects I can't remember at the moment

-most important of all...

-it's a great project

-it's really cool

-bragging rights😎

-if you've incorporated a solid toolpost, there is no compound therefore you can't utilize it for tapers

-you can still use the tail stock offset method to do tapers but if you have a long taper with a great angle, you might not be able to offset the tail stock enough

-you might also need to do a taper with a part between centers

-when using the compound for doing tapers longer than and inch or two, the inconsistant turning of the handle or stoping can transmit ridges into the work surface. If you're using the two hand approach to turn the compound handle, you can't squirt cutting fluid. (Yes, you can use a cordless drill to give yourself power feed, but on mine, the speed was too fast even on low, and controlling the speed was almost useless.)

I've used my homemade TTA to:

- do rifle and shotgun barrels

- make the abour adapter for balancing grinding wheels

- made several wooden spindle wipers for MT3, MT4, NMTB #40

-some other little projects I can't remember at the moment

-most important of all...

-it's a great project

-it's really cool

-bragging rights😎