a smile

Lifelong hobby - cold iron

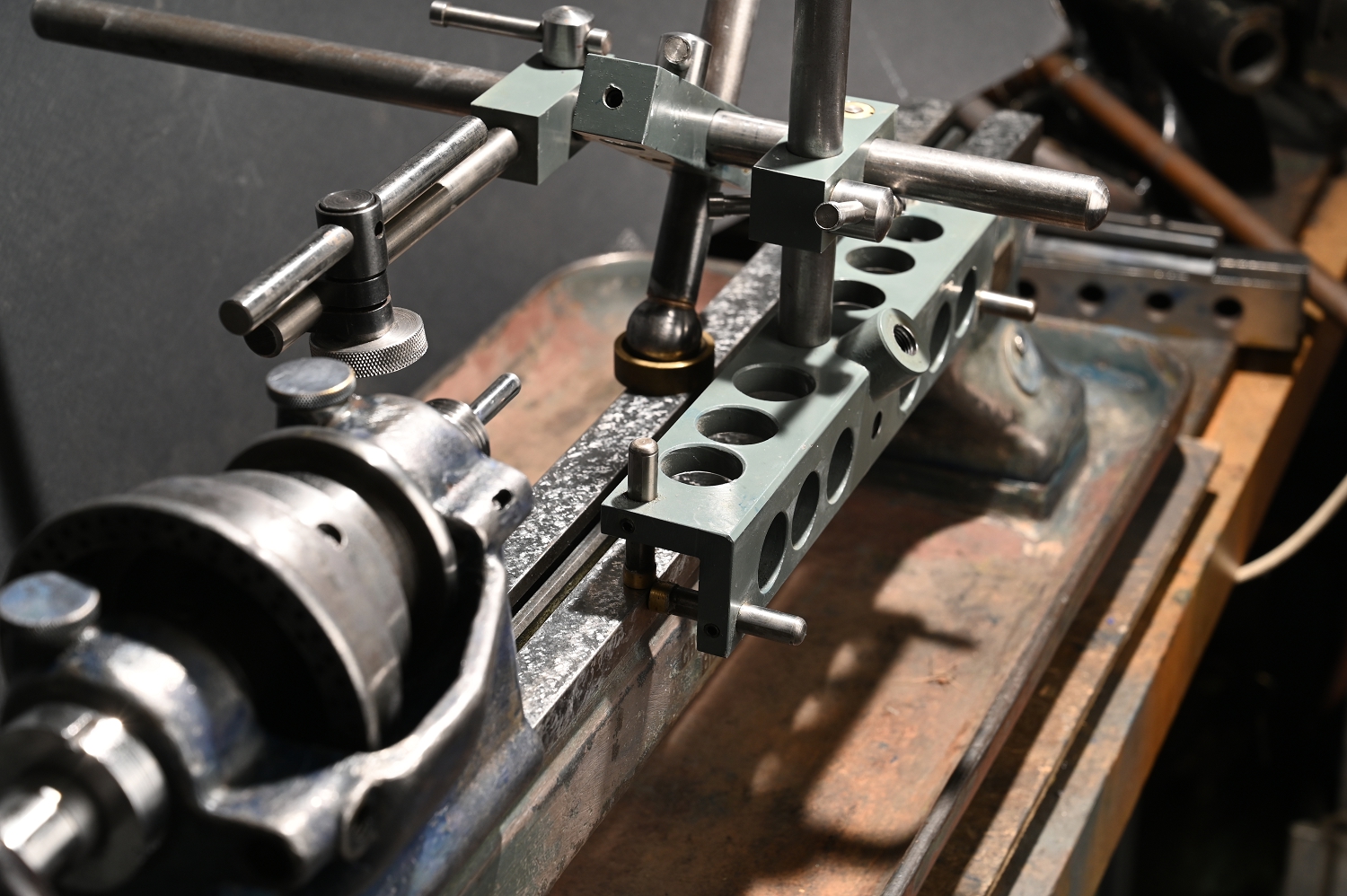

I wonder if adding an elastic rubber band between the two supports can increase the balance and stability of the contact between the cylinder and the dovetail.My tool in that photo is patterned after a tool that machine tool rebuilders have used for a long time.

@Mcgyver has a good write up on his version on his site. It’s much better than mine.

Versatility of the Alignment Tool - Metallum

the Versatility of the Alginment Tool I know, its rather unbecoming to toot ones own horn, however when an idea works out this well I just have to tell someone! The main ‘foot’ of the alignment differs greatly from the Kingway Alignment tool. Its a 90 degree arrangement with two positions for...www.metallum.shop

I think the stability of the support and the contact pressure with the left and right dovetails will affect the accuracy of the measurement, so I hope a professional engineer can help me answer the question.