eotrfish

Ultra Member

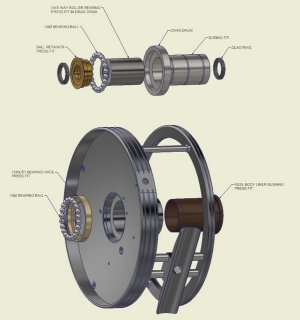

Here's another one from this winter's work...

These reels are an interesting challenge because of all the components that must stack up to +/- .001" in the final assembly. I try for +/-.0005 on the critical lengths and then trim one bushing and one arbor of the final assembly. Usually I only have to remove .003 - .005 to make everything stack up correctly.

These reels are an interesting challenge because of all the components that must stack up to +/- .001" in the final assembly. I try for +/-.0005 on the critical lengths and then trim one bushing and one arbor of the final assembly. Usually I only have to remove .003 - .005 to make everything stack up correctly.