-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fly Reels

- Thread starter eotrfish

- Start date

eotrfish

Ultra Member

You just put a little dab of GG on a bit of folded paper towel and apply to the spinning part. Spin the part and polish until no longer tacky. The glue should be dry enough to re-apply in less than 1/2 hour. Half a dozen coats should be enough for a durable finish. Rubbed on GG is a common finish for bamboo fly rods.Beautiful work. I'm not familiar with using Gorilla Glue for finishing, how do you keep it from expanding or do you let it expand and shape and polish on the lathe?

eotrfish

Ultra Member

Good morning!

It's time for an update of my reel production...

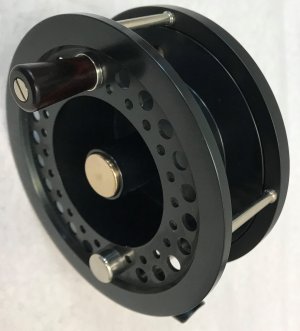

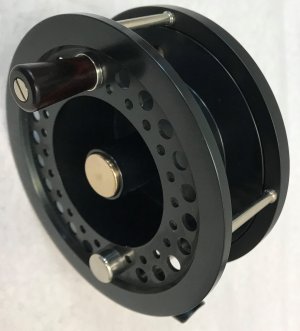

First up is a pair of 4" drawbar drag large arbor reels. These are fairly simple to build, maintain and operate. Drag is provided by a tension rod which loads the spool onto the cork covered drag plate. A little Neatsfoot oil on the cork is about the only maintenance required.

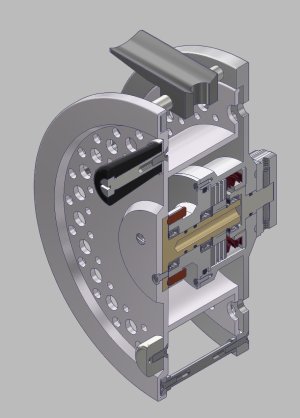

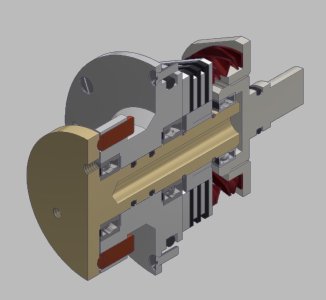

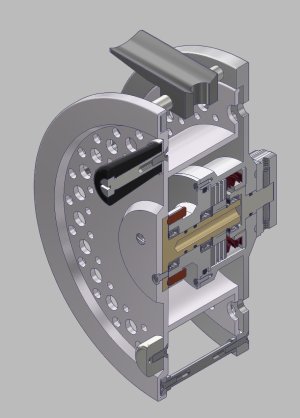

Next a pair of 4" Rulon/Stainless sealed drag reels. This is a more complicated design which requires a one-way bearing and a stack of alternating Rulon and Stainless discs. The hex shaped Rulon discs are held stationary in an internal hex in the reel body. A set of Stainless discs are pinned to the one-way bearing and rotate with the spool. Drag is provided by compressing the wave spring onto the drag stack.

Drag assembly design

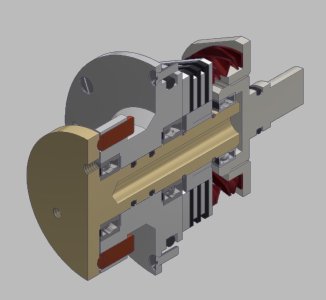

The guts of the drag assembly

It's time for an update of my reel production...

First up is a pair of 4" drawbar drag large arbor reels. These are fairly simple to build, maintain and operate. Drag is provided by a tension rod which loads the spool onto the cork covered drag plate. A little Neatsfoot oil on the cork is about the only maintenance required.

Next a pair of 4" Rulon/Stainless sealed drag reels. This is a more complicated design which requires a one-way bearing and a stack of alternating Rulon and Stainless discs. The hex shaped Rulon discs are held stationary in an internal hex in the reel body. A set of Stainless discs are pinned to the one-way bearing and rotate with the spool. Drag is provided by compressing the wave spring onto the drag stack.

Drag assembly design

The guts of the drag assembly

Beautiful work as always!

Coincidentally I was just thinking of you the other day when I as watching this YouTube engraving artist. Have you ever considered going down this path? Or maybe these reels take enough of your fun time as is LoL. (random internet pic)

Coincidentally I was just thinking of you the other day when I as watching this YouTube engraving artist. Have you ever considered going down this path? Or maybe these reels take enough of your fun time as is LoL. (random internet pic)

eotrfish

Ultra Member

Thanks Peter

That's a pretty looking reel. I've seen a few more in person and always thought it would be a good idea. I did consider going down the engraving rabit hole. I joined an engraving forum, shopped for equipment and looked at registering for a week long course. I guess that I just settled for basic information laser engraved on some of my reels. When my buddy no longer has access to his laser engraver I may have to revisit the manual engraving plan.

I made 5 of these clock reels while I was working on the 4 that I previously posted - they would have been good candidates for manual engraving

That's a pretty looking reel. I've seen a few more in person and always thought it would be a good idea. I did consider going down the engraving rabit hole. I joined an engraving forum, shopped for equipment and looked at registering for a week long course. I guess that I just settled for basic information laser engraved on some of my reels. When my buddy no longer has access to his laser engraver I may have to revisit the manual engraving plan.

I made 5 of these clock reels while I was working on the 4 that I previously posted - they would have been good candidates for manual engraving

Last edited:

johnnielsen

John (Makonjohn)

Beautiful to look at. I know it takes painstaking attention to do such work and ,Eotrfish, you accomplish it with every piece. Amazing.

Nice. Can't wait to see them in 'REEL' life HaHa

I have a question - not sure if this is part of your designs. Do you use typically micro dowel pins in the mechanism? If so, are you buying specific reamers to achieve light press fit (for assembly) and/or for precision free rotation fit?

I have a question - not sure if this is part of your designs. Do you use typically micro dowel pins in the mechanism? If so, are you buying specific reamers to achieve light press fit (for assembly) and/or for precision free rotation fit?

eotrfish

Ultra Member

I use 1/16" dowel pins sparingly - usually to lock a couple of threaded parts together. I don't recall using any for a free rotation fit. I just use a nominal 1/16" reamer or a 1/16" carbide drill. If the pin is loose in the hole I'll either add a dab of Loctite 680 or flatten the pin a few 1/10ths for an interference fit.

eotrfish

Ultra Member

Thanks Tomc938

I came across some photos of another group of reels that I made last year. I originally hadn't intended to make these but had purchased 3 leather cases that I thought would fit some of my other reels. It turned out that the cases were too narrow for any of my reels so I designed this set of reels to fit the cases. These use 0-80 screws for all the pillars and drag parts so there was a bit of a pucker factor making sure that I didn't have to remake any parts. All's well that ends well!

I came across some photos of another group of reels that I made last year. I originally hadn't intended to make these but had purchased 3 leather cases that I thought would fit some of my other reels. It turned out that the cases were too narrow for any of my reels so I designed this set of reels to fit the cases. These use 0-80 screws for all the pillars and drag parts so there was a bit of a pucker factor making sure that I didn't have to remake any parts. All's well that ends well!

eotrfish

Ultra Member

The leather cases are generally custom made for reels. There cases are from Olaf Kundras in Germany. There is also a fellow in Oregon, Arne Mason, who although recently retired, has outfitted untold numbers of reels with his fine leatherwork. Here's an example of an Arne Mason case.

Dan Dubeau

Ultra Member

Wow, what a fantastic thread. Absolutely beautiful reels.