-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DavidR8's shop shenanigans

- Thread starter David

- Start date

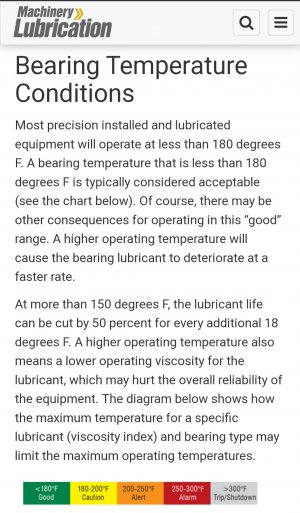

Thank you, appreciate that!I don't have much experience adjusting bearing preload. I've only adjusted the spindle bearings of my tool and cutter grinder, but I found this article helpful.

Have a look at my post, when I measured temps after adjusting the preload. But like I said, I'm no expert, and I don't know how the temperatures differ from the bearings to the housing.

Post in thread 'Clarkson Mk2 Tool and Cutter Grinder' https://canadianhobbymetalworkers.com/threads/clarkson-mk2-tool-and-cutter-grinder.8833/post-130846

Post in thread 'Clarkson Mk2 Tool and Cutter Grinder' https://canadianhobbymetalworkers.com/threads/clarkson-mk2-tool-and-cutter-grinder.8833/post-130846

Thanks, my temps are definitely lower.Have a look at my post, when I measured temps after adjusting the preload. But like I said, I'm no expert, and I don't know how the temperatures differ from the bearings to the housing.

Post in thread 'Clarkson Mk2 Tool and Cutter Grinder' https://canadianhobbymetalworkers.com/threads/clarkson-mk2-tool-and-cutter-grinder.8833/post-130846

After the 30 min run I took a .025 cut at 900 rpm (a bit fast for 1.25 diameter stock) The finish was very nice with no trace of chatter or harmonics.

Well the gear experiment was a bust.

@jcdammeyer can Alibre Pro design gears?

@jcdammeyer can Alibre Pro design gears?

Doggggboy

Ultra Member

If you use F360, would this work for you?

apps.autodesk.com

apps.autodesk.com

GF Gear Generator | Fusion | Autodesk App Store

A basic gear design application for enthusiasts and professionals alike. With the 11 different variants, you will be able to implement gearing mechanisms into your designs as easy as it gets!

Cool.If you use F360, would this work for you?

GF Gear Generator | Fusion | Autodesk App Store

A basic gear design application for enthusiasts and professionals alike. With the 11 different variants, you will be able to implement gearing mechanisms into your designs as easy as it gets!apps.autodesk.com

So long as it doesn't require the paid version of F360.

Well the gear experiment was a bust.

What's wrong with the gear you printed?

The bore is too small and it's too thin to drill it out. So thin that I doubt it would actually hold up.What's wrong with the gear you printed?

The bore is too small and it's too thin to drill it out. So thin that I doubt it would actually hold up.

How did you generate the STL file for it?

I found it on Thingiverse.How did you generate the STL file for it?

I did this gear back in March of 2022 so it's been a while since I played with making gears. It's a python script where you fill in parameters and it generates the gear. I also have the gearotic program written by the guy that designed MAC2/3Well the gear experiment was a bust.

@jcdammeyer can Alibre Pro design gears?

The gears worked out quite well as 3D printed.

I don't recall why this Project #42 was put on hold.

I'm on the fence about upgrading to Design Pro but my desire to make patterns and now this has me strongly considering the upgrade.I did this gear back in March of 2022 so it's been a while since I played with making gears. It's a python script where you fill in parameters and it generates the gear. I also have the gearotic program written by the guy that designed MAC2/3

View attachment 40733

The gears worked out quite well as 3D printed.

View attachment 40734

I don't recall why this Project #42 was put on hold.

I found it on Thingiverse.

My free version of 360 has a gear generator in it. Seems to work quite well. It was something you had to add in to the tool kit. I don't remember the details of doing that, it's been well over a year since I did that.

This was for my shaper. The 3D printed version worked quit well but I gave up on the project after realizing the internal thread was a square thread. The plan was to get @Tom O to make it out of brass in on his CNC mill.

Last edited:

Isn't that always the problem. Spend hours figuring it out. Use it for that project. Then a year later barely even remember doing it.My free version of 360 has a gear generator in it. Seems to work quite well. It was something you had to add in to the tool kit. I don't remember the details of doing that, it's been well over a year since I did that.

View attachment 40735

This was for my shaper. The 3D printed version worked quit well but I gave up on the project after realizing the internal thread was a square thread. The plan was to get @Tom O to make it out of brass in on his CNC mill.

Here's the python code for creating the gear. I'm sure if you go into the Alibre Help forum there will be information for more or different kinds of gears.

Python:

# Gear Generator Script

# Used as a demonstration of how to create a custom utility

# for use with Alibre Design

Units.Current = UnitTypes.Millimeters

# default settings

NumberofTeeth = 20

PitchDiameter = 30

PressureAngle = 20

Thickness = 3

Win = Windows()

ScriptName = 'Gear Generator'

# create dialog window and show to user

Options = []

Options.append([None, WindowsInputTypes.Image, 'GearGenerator.png', 170])

Options.append(['Number of Teeth', WindowsInputTypes.Integer, NumberofTeeth])

Options.append(['Pitch Diameter (mm)', WindowsInputTypes.Real, PitchDiameter])

Options.append(['Pressure Angle', WindowsInputTypes.Real, PressureAngle])

Options.append(['Thickness (mm)', WindowsInputTypes.Real, Thickness])

Values = Win.OptionsDialog(ScriptName, Options, 170)

if Values == None:

sys.exit()

print "Working..."

# get user inputs

NumberofTeeth = Values[1]

PitchDiameter = Values[2]

PressureAngle = Values[3]

Thickness = Values[4]

# get current part

MyPart = CurrentPart()

# get the plane to create the gear on

GearPlane = MyPart.XYPlane

# create the sketch then extrude it

ProfileSketch = MyPart.AddGearNP("Profile", NumberofTeeth, PitchDiameter, PressureAngle, 0, 0, False, GearPlane)

Gear = MyPart.AddExtrudeBoss("Gear", ProfileSketch, Thickness, False)

print "Done"