Indeed, I have plans to make a new cabinet/workbench and I shudder to think of what the materials would cost. I have the 100# full extension drawer slides but plywood has gone through the roof.I found some units at... guess where... Ikea again. But they have improved over my vintage. Legitimate steel bearing slides with stops, beefier box & retention hardware. They had a system with identical box dimensions but one had a filing cabinet bottom drawer which I actually preferred over a bank of drawers only because I could put tall stuff in there. But with all the pandemic rigmarole they were perpetually out of stock. This went on for better part of a year & I just gave up. Then about a month ago I checked again. Lots of drawer units but discontinued or redesign of the deep drawer unit. I figured I wanted this over & with so just bit the bullet. To make me feel a bit better I couldn't even buy the materials at Home Depot never mind the work.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Daily Shop Improvement

- Thread starter Janger

- Start date

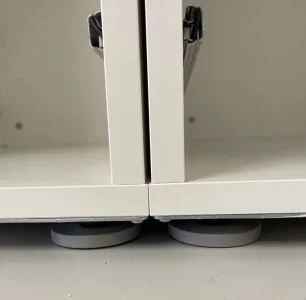

It didn't take me long to assemble the units. I also bought these leveling pucks & screwed them to the bottom. My buddy helped me with the leveling & assembly. He is much better at this stuff than me. We left the outer corner brackets but moved the adjuster plates to straddle 2 boxes so they kind of tie 2 together & reduce the adjusting. I pulled out all the old stuff out. Found a bunch of long lost missing hardware that had rolled under over the years. (Sorry no tail stocks). Got it in place & voila.

Attachments

but plywood has gone through the roof.

Apparently so much so, that thieves cut through the wire fence in order to cart off the shops wood supply at the local HS my wife works at

Last edited:

Apparently even though the rails have a forward facing arrow, its possible to orient the box incorrectly (upside down) such that the middle rail heights are different & therefore middle drawers don't fit. Discovering this on the home stretch with the whole assembly leveled & table top screwed on was not a welcome surprise. I removed the rails & carefully re positioned using the neighbors as guides. All is well. Glad it was only one box.

Attachments

Chris Cramer

Super User

I spent a lot of time cleaning my shop, and reorganizing it. I purchased a 9 drawer husky tool chest from home depot, a storage bin rack for my fasteners, added more hangers to my racking, and I mounted a magnetic rod to the wall in front of my work bench. It definitely could use some more work, like storage for my metal, but I've made good progress.

Attachments

Nice. Yes, just to clarify. I don't intend to fill these new units with anything heavy duty. They are too shallow & not up to the task. Although my buddy gave me a good idea - one can cut a doubler drawer bottom out of say 1/4" MDF, lay it in the bottom & it will add more meat than the 1/8" stuff they have which sits in the drawer side & back groove. Kind of acts like doubling a shelf for strength without losing much depth. Anyways with this task mostly wrapped up, next task is a cheapo wall cabinet vs my open floppy bookshelf (currently out of stock Grrrrr...)

And maybe turn attention to mechanic drawers for under the lathe or close proximity where I have some unused room. That would be a perfect spot & heavier duty drawer application for metalworking stuff.

And maybe turn attention to mechanic drawers for under the lathe or close proximity where I have some unused room. That would be a perfect spot & heavier duty drawer application for metalworking stuff.

DPittman

Ultra Member

I've heard of that but have never experienced it myself. Can you post pictures?where I have some unused room

View attachment 14329Don’t zoom in on the welds

Made that yesterday to hang an oversized load banner, at the back of a trailer. It’s just an idea I’m trying, it may work great it may not

that worked awesome....but there’s no good place to store it on the truck. I’m kicking around how to make one in aluminum that would fold up somehow but don’t have anything on paper. It was still worth the time to make up, now I kinda know how to make the next one

View attachment 14446

that worked awesome....but there’s no good place to store it on the truck. I’m kicking around how to make one in aluminum that would fold up somehow but don’t have anything on paper. It was still worth the time to make up, now I kinda know how to make the next one

What's on the trailer?

historicalarms

Ultra Member

I got a hunch that that is the weed harvester....heavy looking thing it is... Weed harvesters Im use to seeing come from Mexico in a bus...

I don’t know I’m always up frontLooking good Blockade Runner, does your oversize load sign not balloon out in the frame while running? Just saying!

It’s mesh and dances a little but from what I’ve seen on stepdeck loads it mostly stays put

I don’t know I’m always up front

It’s mesh and dances a little but from what I’ve seen on stepdeck loads it mostly stays put

Mesh why didn't I think of that, see what happens when you crawl out of bed too early. Thought all truckers use a cam at the back of their cab and trailer? Maybe not.

Ok I have to know what do you do with the seaweed you harvest? and where do you harvest it?

That’s my seaweed harvester

Well I don’t actually own one, I just delivered it. I meant “that’s my seaweed harvester” as in “that’s what I dragged around”Ok I have to know what do you do with the seaweed you harvest? and where do you harvest it?

historicalarms

Ultra Member

Except when .... god forbid it ever happening, you have a "pile-up" and then their insurance company will tell you "is yours from the time it hits your truck until you deliver it intact to us"

Ah yes, the ins and outs of product ownership/bill-of-lading/liability...... Which leads to revenue recognition date.... when can you 'count' the money... is it after the pickup or after the delivery..... I need a career change. Perhaps apprenticing as a deburring specialist at @CalgaryPT 's shop.