I had a little break in the action today and poked around on the Craptex Lathe .

I can only take short intervals of this , I get flustered and walk away , also , I was having trouble with one of my multimeters , this has been going on throughout the entire process of trying to figure out what the hell is wrong with this P.O.S. , for weeks , adding to the frustration.

Todays observations..................

The motor is off the machine right now , both motors are resting , side by side on the bench to be looked at maybe tomorrow .

I spoke with a guy who is a master electrician , he repairs all kinds of industrial equipment , he's quite busy and it might be two weeks before he can have a look .

I've been using an older multimeter for testing , an OTC , it seems to have a mind of it's own and trying to get into the correct range is a pain in the butt , just when you think you are there it starts going crazy , looking at the label on the back tells me it's more crap from China ........... I used to use that meter a lot and liked it , not so much now.

I have a very nice Snapon meter at work that I enjoy using , it's at work though .

I went out to the motorhome and got another multimeter ( DiLog) which scrolls between ranges perfectly and doesn't pick up any transient interference from the fluorescent lights in my shop , this is a meter I've had over thirty years and it still works great .

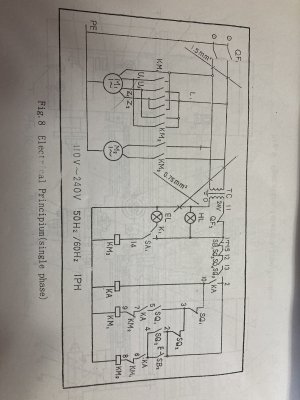

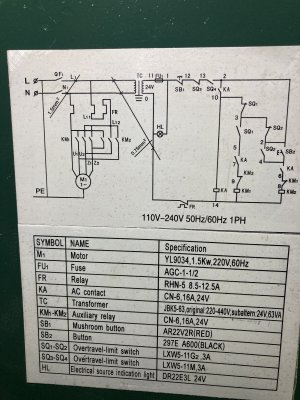

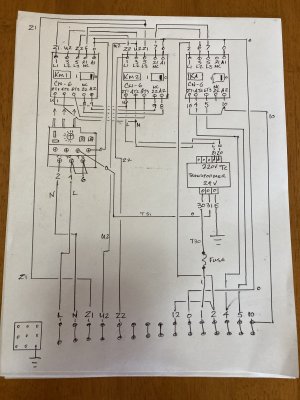

I was able to actually get some measurements off the contactors and observe the behavior of them . The KM1 contactor is for reverse as I initially thought , that's the one with the thermal overload relay connected to it . When you select reverse with the switch on the carriage , it clicks and you can see with the meter that it is doing it's job . The contactor beside it , KM 2 doesn't click at all and appears to be toast , I believe that one is for forward . The funny thing with KM 2 is , when this whole episode began weeks ago , it would click & throw a few sparks around when you tried to select forward with the switch on the carriage , now it's dead .

KA contactor clicks when the lathe has power and stays that way , the funny thing with that one is , you can kill the power to the lathe , unplug it and that contactor remains in the closed position , eventually it clicks and opens up , like , an hour or so later , when I stopped farting around with the lathe and switched to doing other work I had going on , I heard it switch off when I happened to be standing there. This happened to me as well ,the other day when I was tinkering with it and walked away , a short time later I heard a click , it was KA contactor opening up .

I got a new thermal overload relay off of ebay , it came from China , arrived way ahead of what I had expected or what they had projected as a shipping time. this part is sitting off to the side with the start & run capacitors I bought from Amazon.

This morning I ordered three of the correct contactors off ebay , those are shipping from China .

I reached out to the company in Concord Ontario where the first set of contactors came from to see if I could return them , they've been paid and must not care and it's been a week without them returning my email.

I worked on it for an hour or so calmly and then moved on to other more stimulating stuff I have going on. Using an actual working multi meter today was almost like a breakthru !!

Tomorrow is a new day , I'll mess with it some more