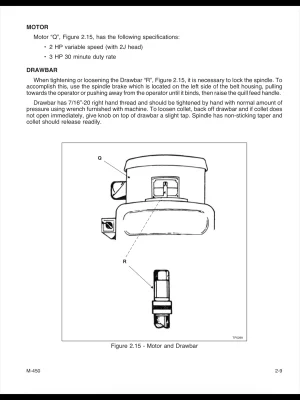

I don't use R8 tooling, but isn't that set screw just to prevent the collet from turning while tightening the draw bar and nothing else?

There is some disagreement on that. I've read countless articles from professional sources that claimed different uses and benefits. I found many of them to have merit. I have synthesized all of that information as follows:

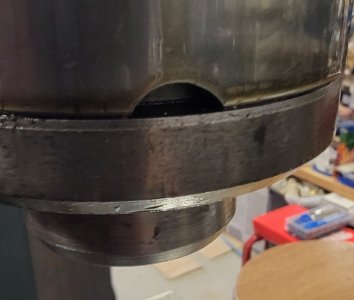

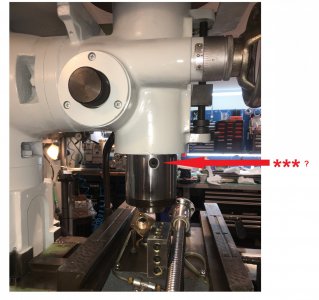

The R8 collet taper is about the shortest of any of the big collets at just under an inch. It also has a faster sharper taper angle. An R8 taper usually serves two purposes - to stop the arbour from turning in the quill AND clamp a tool in the collet.

Given the low probability of properly torquing a drawbar the design was improved to include an alignment pin that could resist a "small portion" of the operating torque when the drawbar torque wasn't perfect and simultaneously assist in torquing a drawbar by preventing a loose collet from spinning.

I do not have any reason not to accept all these explanations. One could easily make sound arguments to the contrary on all of them. But my conclusion was that erring on the side of caution was clearly the safest approach.

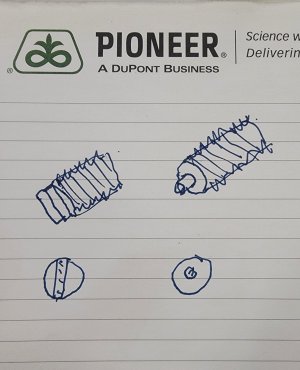

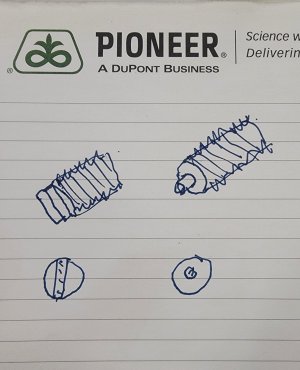

That's why I redesigned my pin to look like the one on the left not like the one on the right. It roughly doubles the strength of the pin - maybe a bit more than double.

Is it necessary? I have no really evidence or information either way. Does it help? Again, I don't know.

However, what I do know is that I have seen what happened to another mill when that pin sheared off and the collet spun in the spindle. I

NEVER EVER want that to happen to me.

I also know that those pins seem to break regularly. In fact, they break so often that there is a fair number of users who simply remove them. That is

NOT EVER GUNNA BE ME! The only reason it would break is if the collet spun.

Therefore, I've chosen to be a wee bit safer, use the pin, and strengthen it a bit too. I consider it cheap insurance.

I can also say that the one I modified as above is still inside my spindle and still working fine.

Last, but not least, the modified screw automatically retains alignment when the keeper screw is installed - no loctite required.