Why do you need all those stiffeners?

They aren’t for stiffness. The tray will be filled with water to catch sparks. The slats hold the material above the water.

Why do you need all those stiffeners?

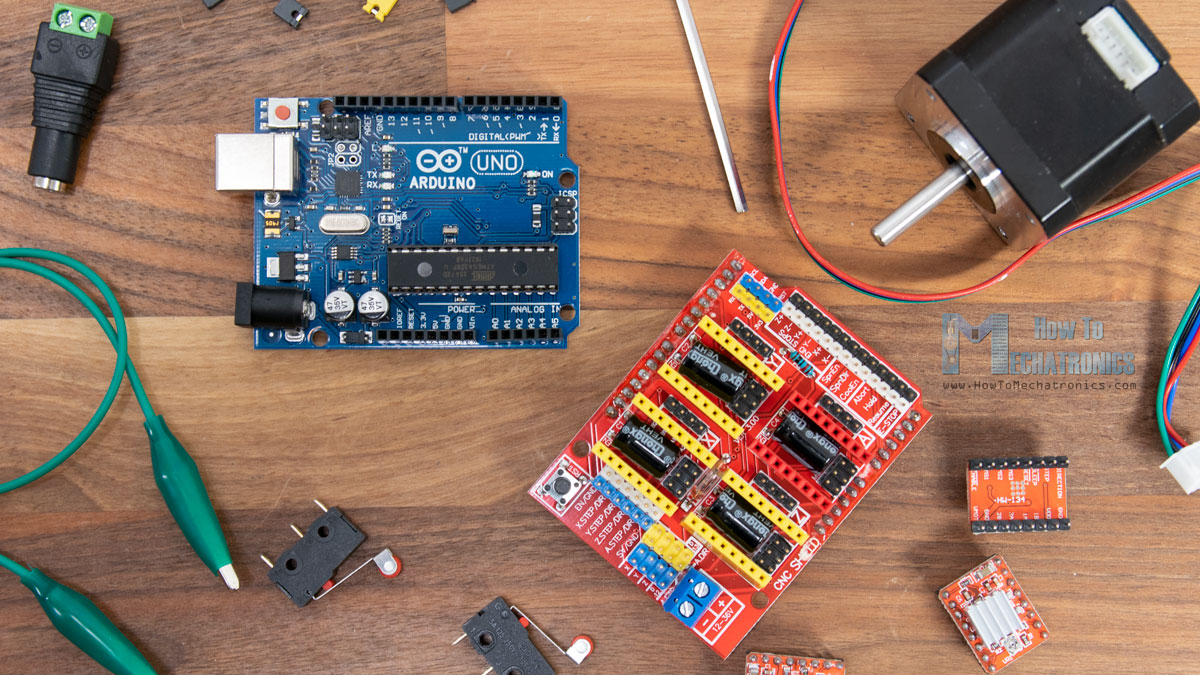

Is that a 6040?I was wondering about that design not showing limit switches I thought those were a important part of the Cnc machines my router just stops till you crank it back which is a pain with the enclosure.

View attachment 14707

This is a first generation design that I want to upgrade the control boards on I’m thinking maybe a centroid system.

I only have a 50A plasma machine which would not cut 1" plate. I suppose if I had an 100A machine it would cut 1" plate.Hey David,

Can you cut 1" thick plate with this?

Craig

You're pretty close.Soooo, trying to get my head around how this works (having never used a CAM program)

Here is what I think. Please interject or correct

Do a drawing in a CAD program ie F360 or FreeCAD

Convert the file to DXF?

Then do what to get it to the Arduino?

Arduino has grbl in it...

any interaction on your part? Serial monitor?

DAC is a little vague after the hardware is complete.

Trying to understand the whole process.

You're pretty close.

Not sure if FreeCad has a CAM side to it but I draw in F360, then switch to the CAM (Manufacturing I think it's called) where you chose the tool, set the feed rate etc. Then you tell it to generate the gcode using the grbl post-processor built into F360. It churns away and spits out a text file full of the coordinates, feed and commands to turn the torch on/off.

Save it to a jump drive and stick it into the control computer. The actual process from there depends a bit on what control software you use.

I like the OpenBuild controller because it has a decent interface.

Then it's basically load the file, turn on the compressor, turn on the plasma machine and press start cycle, stand back and be amazed

Have you built one?

I am a fan of ACORN and they have just added an optical interface for plasma cutter interface.

Yes, the Arduino gets flashed with the grbl software so that it knows what to do with the gcode that it gets from the control software.FreeCAD can generate G-Code, but I have not mastered that yet, ie, need to go through the tutorial again. Pretty straight forward, if I recall correctly. .There is info available on it

CAM Workbench - FreeCAD Documentation

wiki.freecadweb.org

I think I did it once last year to see if it works.

I load it to the Arduino through the controller? In your case, OpenBuild? I remember reading that you started with one software, then switched. I will go look that over too.

Have not built it yet. I wanted to learn a bit about the Arduino first and get more comfortable with stepper motors and the controlling of them. The power feed project for my mill has done that. DAC does not supply any code for the Arduino so, I am guessing, that part is all done with the CAM software and controller software?

Thanks

No I used the Acorn system and purchased it from CNC4PC to get the Clearpath (servo) interface for my mill.Is your system an Acorn system or did you build the hardware and just use their software?

Centriod's (Acorn) software has an simple programming tool called Intercon, which makes it easy to take DfX files and create cut profiles and turn them into G-code specific to Centroid type controllers.Yes, the Arduino gets flashed with the grbl software so that it knows what to do with the gcode that it gets from the control software.

the Arduino board is flashed with the grbl software so that it knows what to do with the gcode it receives from the control software.