gerritv

Gerrit

@MrWhoopee I keep saying the same thing, hence my new avatar. Ppl seem to want to complicate the hobby level with industrial info. I have never been disappointed with AliExpress inserts after I started buying (apparent) name brand ones from DotStripe store. The only tool holder disappointments have happened with the MGEHR type cutoff holders, some are butter, some are solid. No way to tell in advance though :-(

I don't even bother buying inserts for Al, if the finish really matters I plunk in a new edge on a steel style insert.

I admire those who want to spend their time learning to grind drill and HSS cutters. To me it is a steep and long learning curve, with a lot of poor results until you get decent at it. Oversized wandering drill holes are a pain, esp in smaller sizes in work where you already have 10 hours into the part. Buy stub drills from KBC, 5 at a time for common sizes, use a drill sharpener (Drill Doctor 750) to touch them up when you have a bunch to sharpen)

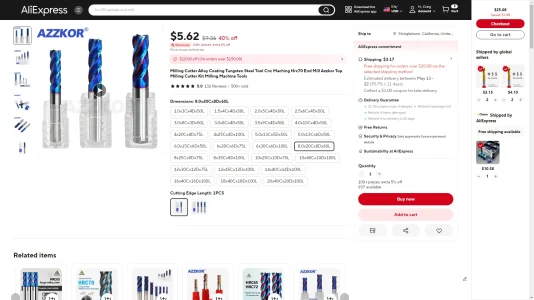

(With my next allowance/pension cheque from UK I will be starting to stock up on carbide stub drills in metric tap/drill and clearance size, package of 10. < CA$12 per package from AliExpress of course).

gerrit

I don't even bother buying inserts for Al, if the finish really matters I plunk in a new edge on a steel style insert.

I admire those who want to spend their time learning to grind drill and HSS cutters. To me it is a steep and long learning curve, with a lot of poor results until you get decent at it. Oversized wandering drill holes are a pain, esp in smaller sizes in work where you already have 10 hours into the part. Buy stub drills from KBC, 5 at a time for common sizes, use a drill sharpener (Drill Doctor 750) to touch them up when you have a bunch to sharpen)

(With my next allowance/pension cheque from UK I will be starting to stock up on carbide stub drills in metric tap/drill and clearance size, package of 10. < CA$12 per package from AliExpress of course).

gerrit

Last edited: