Dusty is one step ahead of me. The heat could be from friction turning but could also be from grinding which should be of no consequence. If you get the same result through the rpm range (start low, progress to high) then I'd start suspecting the HSS. But that's a stretch. Pretty sure that's the country of origin of my KBC T-blades. If anything should cut fine after sharpening & just degrade quicker. Try aluminum (with fluid). A sharp blade should make a nice long continuous chip as you manually apply in feed.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AXA Tool Holder for Tapered Cut Off Blades

- Thread starter YYCHM

- Start date

Dusty is one step ahead of me. The heat could be from friction turning but could also be from grinding which should be of no consequence. If you get the same result through the rpm range (start low, progress to high) then I'd start suspecting the HSS. But that's a stretch. Pretty sure that's the country of origin of my KBC T-blades. If anything should cut fine after sharpening & just degrade quicker. Try aluminum (with fluid). A sharp blade should make a nice long continuous chip as you manually apply in feed.

500 RPM, same as what I ran @Dusty 's blade at. Heat means friction but from where?

Hi Craig, using a ruler is a rough guide. On thin pieces is works quite well, but on larger diameters, it could be way off. Measure and determine your exact centre height to the bed ways, and to your saddle. This way you have different ways of setting tool height. Use a square to determine perpendicularity. The beam of the square on the chuck, and the blade of the square against your parting blade. What material are you parting and what diameter?Yup, a thin ruler was how I set the tool height. Blade is square and sharp. Same stock as what @Dusty 's blade motored through. Dunno.....

You can get heat and rubbing from too slow of a feed. Try the power crossfeed at .002/rev at 4-500 rpm and see what happens. Touch up the blade on an oil stone. Make sure its sharp.

I tried being aggressive on the feed. It just goes so far and stops cutting. I don't think forcing it after that point is a good idea.

What material are you parting and what diameter?

Mild steel, 3/4" dia.

Try doubling your feed, 0.004-0.005. If that doesn't work, reduce your speed, keep the .005 feed. When I magnified that picture you posted with the welded curl, the front face of the blade looks jagged, or is that just the photo.

Try doubling your feed, 0.004-0.005. If that doesn't work, reduce your speed, keep the .005 feed. When I magnified that picture you posted with the welded curl, the front face of the blade looks jagged, or is that just the photo.

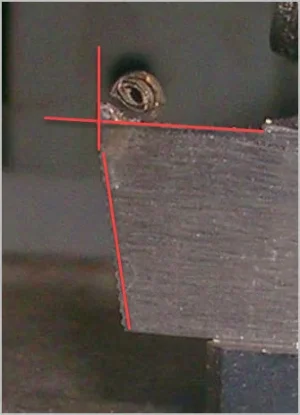

The front of the blade was jagged. I don't know why it came that way, almost knurled. I ground it smooth and increased the angle a smidge in case it was rubbing.

Last edited:

That blade might just be junk

It wasn't cheap by my standards? Why would a substandard blade do this? When you remove the buildup it's still feels sharp?

I once had a new chinese drill bit straighten out the flutes while drilling. It was as soft as cheese. I think i still have it at work. Anyways, if you're trying all the suggestions you've been given, and nothing works, I'd suspect bad grind or bad blade.

Last edited:

RobinHood

Ultra Member

What colour are the sparks when you grind the blade?

On a useless blade I had, they were long and orangish - could not get that thing to work.

There are different grades of HSS out there, not all work well for parting blades.

The ones I did have success, the sparks were typically bright yellow and very short.

On a useless blade I had, they were long and orangish - could not get that thing to work.

There are different grades of HSS out there, not all work well for parting blades.

The ones I did have success, the sparks were typically bright yellow and very short.

Did you grind it at one angle setting or is there a chance you have a more square relief angle directly under the edge? I noticed the same thing about the front face, very rough. Not that it does anything cutting wise, but jest asking about the general prep. Then stone the top surface with fine stone & oil & it should be very sharp. Actually I think I was lazy & ground one of my blades in-situ on the holder. Hard to sketch but the straight relief is actually grind wheel radius, but still came to a point if that makes sense. Very mysterious why the results are so different on same stock.

Attachments

Did you grind it at one angle setting or is there a chance you have a more square relief angle directly under the edge? I noticed the same thing about the front face, very rough. Not that it does anything cutting wise, but jest asking about the general prep. Then stone the top surface with fine stone & oil & it should be very sharp. Actually I think I was lazy & ground one of my blades in-situ on the holder. Hard to sketch but the straight relief is actually grind wheel radius, but still came to a point if that makes sense. Very mysterious why the results are so different on same stock.

I suspected that to and ground the roughness from the from edge and increased the presentation angle a smidge assuming it was rubbing. No change.

A little late to the party and not one to be giving advice on this subject. But perhaps I can be allowed to ask questions.

Is that blade tapered from top to bottom to provide a wedge shape or flat with a rectangular cross section?

Is there any top grind?

Why do the sides of the tip look ground? Or is that from rubbing?

Are you using cutting fluid and if so what fluid and how are you applying it?

Is the presentation slightly clocked such that the sides Start rubbing on the stock more and more as the blade progresses.

What material are you cutting?

I assume you are feeding with the cross slide, but are the carriage and compound locked?

Sure wish I could be there to see your face when you figure this one out.

Is that blade tapered from top to bottom to provide a wedge shape or flat with a rectangular cross section?

Is there any top grind?

Why do the sides of the tip look ground? Or is that from rubbing?

Are you using cutting fluid and if so what fluid and how are you applying it?

Is the presentation slightly clocked such that the sides Start rubbing on the stock more and more as the blade progresses.

What material are you cutting?

I assume you are feeding with the cross slide, but are the carriage and compound locked?

Sure wish I could be there to see your face when you figure this one out.

What colour are the sparks when you grind the blade?

On a useless blade I had, they were long and orangish - could not get that thing to work.

There are different grades of HSS out there, not all work well for parting blades.

The ones I did have success, the sparks were typically bright yellow and very short.

I'd call them long and orange. Definitely not yellow.

I got the blade from these guys

The one they sent me is labeled HSS 1/16 X 1/2 X 4-1/2 CHINA, no indication of Cobalt on it.

The blade @Dusty sent me is labeled GROZ COBALT.

The one they sent me is labeled HSS 1/16 X 1/2 X 4-1/2 CHINA, no indication of Cobalt on it.

The blade @Dusty sent me is labeled GROZ COBALT.

Last edited: