Here is my video on angle grinders. Is it the most dangerous tool? This isn’t advice - just my observations. Use your own sense please and take care of yourself. What else should you be on the lookout for?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Angle grinders. Most dangerous tool in the shop?

- Thread starter Janger

- Start date

Tool

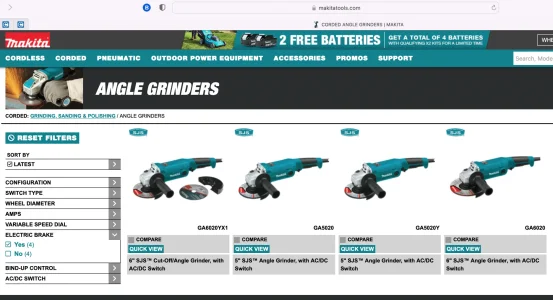

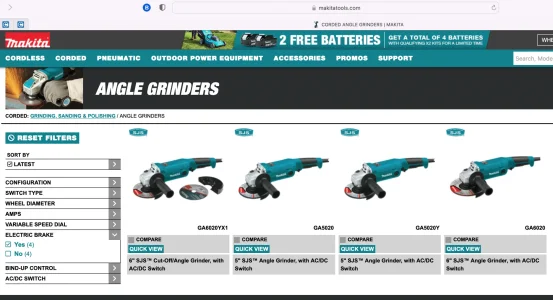

Makita make some grinders with brakes. not sure about the other brands I haven't looked.

cordless

www.kmstools.com

www.kmstools.com

$239 on amazon 🙁 seems like a lot.

Oh found another one:

$149 that is better. Dewalt has a few I noticed too.

corded...

cordless

Makita 18V 5" Angle Grinder with Variable Speed, Electric Brake and Brushless Motor

With a variable speed switch, electric brake, efficient and powerful brushless motor, and Active Feedback sensing Technology, the Makita DGA513Z 18 volt 5" cordless angle grinder is equipped with a lockable On/Off switch on the saddle and is designed to d

$239 on amazon 🙁 seems like a lot.

Oh found another one:

$149 that is better. Dewalt has a few I noticed too.

corded...

Ok, found a video on those 'walter' discs. At the 0:20 second mark they describe the 'backplate'. My cheap POS grinder has this as an integral piece I can't remove it. But those discs just 'spin-on' once you have then in place.

That's two that don't like the Bosch grinder. I have that grinder and the lockable switch is the reason I like it. I admit, it's not a great grinder. It's pretty much an entry level unit, but I do a lot of one handed grinding with flapper discs and being able to lock the switch on is helpful. For heavy duty grinding, I use a rat tail.Thanks for this John.

I have a Bosch angle grinder just like that and pretty much hate it for all of the reasons you describe.

Thanks!! I have operated a lot of grinders and none of them have had the brake. I wish my 7" Makita had one, it is a monster and sure would be nice to have on it. The next time I am buying a grinder I will be looking for one with a brake.Makita make some grinders with brakes. not sure about the other brands I haven't looked.

cordless

Makita 18V 5" Angle Grinder with Variable Speed, Electric Brake and Brushless Motor

With a variable speed switch, electric brake, efficient and powerful brushless motor, and Active Feedback sensing Technology, the Makita DGA513Z 18 volt 5" cordless angle grinder is equipped with a lockable On/Off switch on the saddle and is designed to dwww.kmstools.com

$239 on amazon 🙁 seems like a lot.

Oh found another one:

$149 that is better. Dewalt has a few I noticed too.

corded...

View attachment 22181

SomeGuy

Hobbyist

I don't care how much more they cost, I use flap wheels over grinding wheels 99% of the time...I have never ran a grinder without the guard and I always wear the appropriate bits of PPE. It's like any tool, you just need to respect it.

Also, the Dewalt cordless grinders with brakes are a far less lethal version.

Also, the Dewalt cordless grinders with brakes are a far less lethal version.

Have to admit I've been lucky so far with angle grinders. I own 6 of them. I think when I was 15 or so and first started metal working it was one of the first tools I learned about safety on. It was the tool that taught me the idea of having multiple face shields and hanging them above all your workstations so you don't have to make that decision about saving a few seconds by not walking to the other side of your shop to grab the one you left on another bench.

The rules I learned:

- Always wear thick gloves

- Always use a face shield

- Never lay the grinder flat during spindown (or at all to drive home the point)

- Keep guard in place unless absolutely necessary to remove

- Use two hands and handle provided (I like models where you can put the handle on the top or at the sides)

- Don't be the first clown to try out new attachments for grinders. Many are deadly and there is insufficient experience even on the internet to guide you (chainsaw blades, stones of death, etc.)

- Check and replace consumables when you see any damage, especially cutting disks

- Use the smallest size tool that does the job properly. For example, I have a smaller 3.5" Makita I use exclusively with cutting wheels. It is small enough and light enough for those times where you need to use it one handed, but lacks the same kickback and inertia of larger models.

- Give some thought to direction of debris and sparks prior to startup. I keep my guards snug, but loose enough that I can reposition them by hand to direct the sparks away from my face, feet, etc.

- Always check clothing for debris before going back in house. A leather welding jacket is best, but if not at least brush/blow yourself off. This is especially important with wire brushes as those wires stick into clothing, then fall off inside the house. I used to have a pair of glasses with magnets on the sides for sunglasses, and the wire pieces would stick to them, then fall off next to your eye eventually. Not good.

- Always unplug/remove battery when changing consumables

This last point is the closest I ever got to a an injury. I don't change out consumables as often because I basically have a devoted grinder for each type of consumable. So I once got out of practice and even with the safety switch managed to start it up as I was positioning the wrenches. Lesson reinforced.

The rules I learned:

- Always wear thick gloves

- Always use a face shield

- Never lay the grinder flat during spindown (or at all to drive home the point)

- Keep guard in place unless absolutely necessary to remove

- Use two hands and handle provided (I like models where you can put the handle on the top or at the sides)

- Don't be the first clown to try out new attachments for grinders. Many are deadly and there is insufficient experience even on the internet to guide you (chainsaw blades, stones of death, etc.)

- Check and replace consumables when you see any damage, especially cutting disks

- Use the smallest size tool that does the job properly. For example, I have a smaller 3.5" Makita I use exclusively with cutting wheels. It is small enough and light enough for those times where you need to use it one handed, but lacks the same kickback and inertia of larger models.

- Give some thought to direction of debris and sparks prior to startup. I keep my guards snug, but loose enough that I can reposition them by hand to direct the sparks away from my face, feet, etc.

- Always check clothing for debris before going back in house. A leather welding jacket is best, but if not at least brush/blow yourself off. This is especially important with wire brushes as those wires stick into clothing, then fall off inside the house. I used to have a pair of glasses with magnets on the sides for sunglasses, and the wire pieces would stick to them, then fall off next to your eye eventually. Not good.

- Always unplug/remove battery when changing consumables

This last point is the closest I ever got to a an injury. I don't change out consumables as often because I basically have a devoted grinder for each type of consumable. So I once got out of practice and even with the safety switch managed to start it up as I was positioning the wrenches. Lesson reinforced.

Good point on the size of the grinder, I have an arbor for zip discs for air die grinders. Standard size is 3” but you can order 4” zip discs too. Works great in straight or 90 degree die grinders, great for tight spots where an electric grinder won’t fitHave to admit I've been lucky so far with angle grinders. I own 6 of them. I think when I was 15 or so and first started metal working it was one of the first tools I learned about safety on. It was the tool that taught me the idea of having multiple face shields and hanging them above all your workstations so you don't have to make that decision about saving a few seconds by not walking to the other side of your shop to grab the one you left on another bench.

The rules I learned:

- Always wear thick gloves

- Always use a face shield

- Never lay the grinder flat during spindown (or at all to drive home the point)

- Keep guard in place unless absolutely necessary to remove

- Use two hands and handle provided (I like models where you can put the handle on the top or at the sides)

- Don't be the first clown to try out new attachments for grinders. Many are deadly and there is insufficient experience even on the internet to guide you (chainsaw blades, stones of death, etc.)

- Check and replace consumables when you see any damage, especially cutting disks

- Use the smallest size tool that does the job properly. For example, I have a smaller 3.5" Makita I use exclusively with cutting wheels. It is small enough and light enough for those times where you need to use it one handed, but lacks the same kickback and inertia of larger models.

- Give some thought to direction of debris and sparks prior to startup. I keep my guards snug, but loose enough that I can reposition them by hand to direct the sparks away from my face, feet, etc.

- Always check clothing for debris before going back in house. A leather welding jacket is best, but if not at least brush/blow yourself off. This is especially important with wire brushes as those wires stick into clothing, then fall off inside the house. I used to have a pair of glasses with magnets on the sides for sunglasses, and the wire pieces would stick to them, then fall off next to your eye eventually. Not good.

- Always unplug/remove battery when changing consumables

This last point is the closest I ever got to a an injury. I don't change out consumables as often because I basically have a devoted grinder for each type of consumable. So I once got out of practice and even with the safety switch managed to start it up as I was positioning the wrenches. Lesson reinforced.

Follow up. My makita grinder with brake showed up. Here is me testing it. I am disappointed. I expected it to stop quickly. Within 1s. Can someone with a 5” angle grinder test how long it takes to stop?

For the record this is a Makita GA5020 angle grinder with brake and it takes about 3.5s to stop.

EDIT -> Re uploaded video.

For the record this is a Makita GA5020 angle grinder with brake and it takes about 3.5s to stop.

EDIT -> Re uploaded video.

Last edited:

SomeGuy

Hobbyist

Follow up. My makita grinder with brake showed up. Here is me testing it. I am disappointed. I expected it to stop quickly. 1s. Can someone with a 5” angle grinder test how long it takes to stop?

How long does it take? My two grinders with brakes spin down 90% of the way within a half a second or so, but then the last 10% seems they disengage the brake and let slow naturally.

I'll do a short this weekend with my 60v dewalt with a 6" wheel for you to compare though.

Follow up. My makita grinder with brake showed up. Here is me testing it. I am disappointed. I expected it to stop quickly. 1s. Can someone with a 5” angle grinder test how long it takes to stop?

My Dewalt takes around 6-7 seconds to stop. It’s a DW831, I don’t see a brake listed on Dewalts website. Sitting side by side you can compare it with a die grinder. Also you can see the difference between a flat zip disc and the raised centre style. Anything that keeps it further away from fingers is a good thing

My Dewalt takes around 6-7 seconds to stop. It’s a DW831, I don’t see a brake listed on Dewalts website. Sitting side by side you can compare it with a die grinder. Also you can see the difference between a flat zip disc and the raised centre style. Anything that keeps it further away from fingers is a good thinghistoricalarms

Ultra Member

You haven't experienced Kaos until you have your head & shoulders inside combine header grinding off a gob of weld so grain/straw wont slow down on its journey and have that 7" grinder grab & explode the wheel...that was more excitement in a 1/2 second than I want to experience again. I had numerous pin prick holes to the face around my safety glasses but nothing that didnt heal up in couple of days.....I can tell you that ducking is a waisted effort, its all over in an instant.

SomeGuy

Hobbyist

Follow up. My makita grinder with brake showed up. Here is me testing it. I am disappointed. I expected it to stop quickly. 1s. Can someone with a 5” angle grinder test how long it takes to stop?

Just for you 🙂

My five inch Makita takes at least five seconds to come to a stop. Will verify that today.Follow up. My makita grinder with brake showed up. Here is me testing it. I am disappointed. I expected it to stop quickly. 1s. Can someone with a 5” angle grinder test how long it takes to stop?

Follow up. My makita grinder with brake showed up. Here is me testing it. I am disappointed. I expected it to stop quickly. 1s. Can someone with a 5” angle grinder test how long it takes to stop?

For the record this is a Makita GA5020 angle grinder with brake and it takes about 3.5s to stop.

WTF! happened to my video ??? Music? Polka dots? OMG. you can't hear the grinders or me counting the timings. Sorry to expose you fine gentlemen to this. I am ashamed and will re-upload... I was trying to use the vimeo phone app and disaster ensued.

My grinder story is when I set my coveralls on fire while cutting some square tubing...

I had thick gloves, hearing protection, face shield and of course the coveralls, so I thought I was safe.

It never occured to me that the sparks hitting my coveralls would eventually build up and then set it on fire…

I had thick gloves, hearing protection, face shield and of course the coveralls, so I thought I was safe.

It never occured to me that the sparks hitting my coveralls would eventually build up and then set it on fire…

SomeGuy

Hobbyist

Ok here is the video in it's improved and original format. no puppies in the bouncy castle this time.

Yeah, that brake definitely doesn't work as well as the ones on my Dewalts...now granted mine are cordless, so probably lower RPM but even the 6" comes to a stop in just a smidge over a second.