Didnt have a whole lot of airplane ambition today, made a sign for the house with the cnc router, that led into working on the airplane, lol

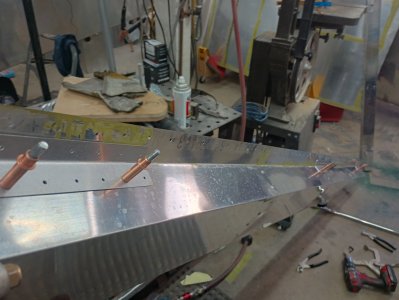

Made up some re-enforcement tabs for the aileron hinge's on the cnc with some of the salvaged .025 LE skin.

The plans are designed around flexing the skin for the hinge, many guys change over to a piano hinge to reduce the stick forces in roll, as its reported by many to be quite heavy compared to pitch.

I will cut the extra aileron skin when i have the hinge in hand, for now it will stay long

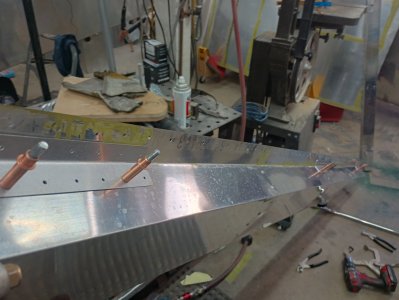

Made up some re-enforcement tabs for the aileron hinge's on the cnc with some of the salvaged .025 LE skin.

The plans are designed around flexing the skin for the hinge, many guys change over to a piano hinge to reduce the stick forces in roll, as its reported by many to be quite heavy compared to pitch.

I will cut the extra aileron skin when i have the hinge in hand, for now it will stay long