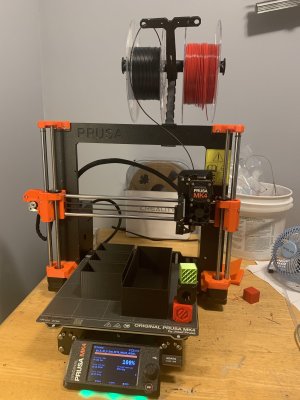

If one were to buy this printer (just sayin'

🙂 ) what 'extras' should be ordered with it?

https://ca.store.bambulab.com/products/a1?variant=44732502638832

I know from experience that it's the 'add-ons' that drive up the cost quickly. e.g. the bargain lathe..

🙂

Is the AMS very useful if only single colour prints are planned?

Without the AMS multi-spool holder, how is the spool held?

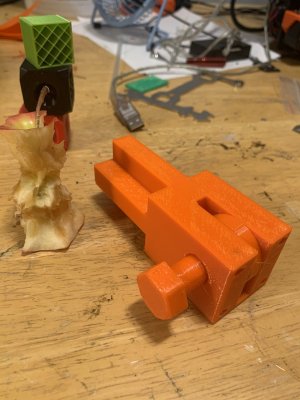

What filament PLA or PETG for a beginner?

Should extra nozzles be ordered?

etc...

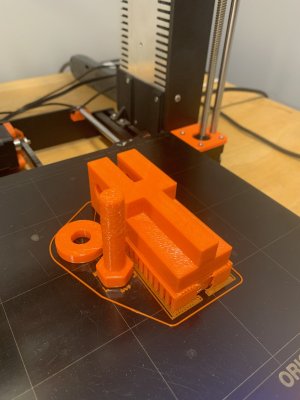

I don't understand why I am tempted by this - it's not like I have ever said "No I don't want that part in metal- don't you have it in soft plastic?"

🙂

Next stop is thingiverse to see if there is actually $750 worth of things there that I want to make for myself.

The odds of me learning enough CAD to design parts are very slim.