ChazzC

Ultra Member

I Did Something on Purpose (this time)

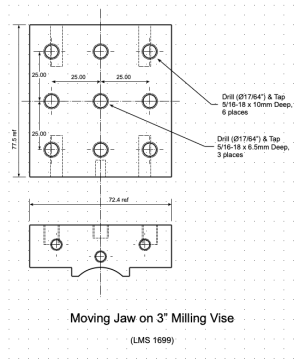

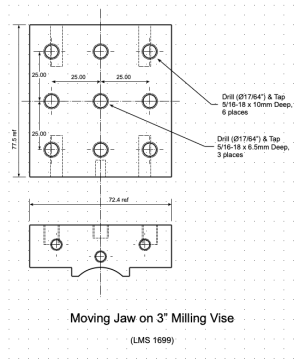

From this post, I did this:

Started with just drilling holes for 10-32, then changed my mind and went with 10-32 x 5/16-18 inserts (didn't think the 10-32 in the cast steel-ish would last):

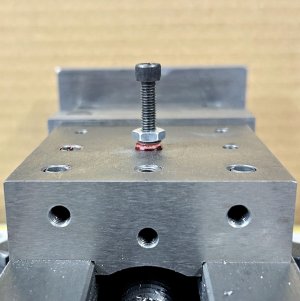

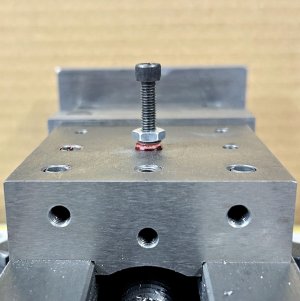

The three center holes are shallower to clear the nut. While the outer holes intersect the M6 tapped holes for mounting the jaw plates, the attaching screws only go 8mm deep, so no problems. The 10-32 x 5/16-18 inserts have thin walls, so the outside threads have a shallower profile and require a larger tap drill (E-Z Lok specs an "I" (0.272"), but I crept up on this from an "F" and stopped at 17/64", which gave me 0.269" actual. I tapped the hole (plug & bottom), cleaned the thread locker off of an insert and "offered it up:" it went in easily with no play so I installed the first insert using the E-Z Lok driver bit (not this insert, but it shows the technique):

The driver bit was held in a 1/4" hex-to-square adapter, mounted on a T-handle; the back of the T-handle has a Ø5mm hole, which was almost a perfect fit for the cone-end of my tap follower (see this thread) to keep things reasonably square.

The inserts are 5/16" long, which won't work in a 6.5mm deep hole, but there are no threads at the drive slot, so I faced off the ends of three inserts:

Before & After facing:

And used a nut & SHCS to install the short inserts:

I also added a little extra thread locker, just for insurance.

For those who want to know, here is the sequence of operations I followed:

* Clamped the vise tight, then used an edge finder to locate the center of the moving jaw; moved to the first hole location (upper left), opened the workspace view on TouchDRO and added the first point (ignore the Z-axis location).

• Using a stubby #21 drill bit, touched off on the top of the jaw, zero'd the Z-Axis and drilled 6.5mm deep.

• Moved to the next hole location, added the second point to the workspace, touched off, drilled 6.5mm deep.

* Moved to the third hole location, etc.

* After drilling all of the holes, I tapped the last (9th) hole and ran a 10-32 SHCS in. I wasn't happy with the slightly loose fit, and decided to see what 10-32 inserts were available. McMaster had the 10-32 x 5/16-18 thin-wall inserts, so I ordered two packs of 10, plus a driver. While waiting for the parts to arrive, I dug out the 1/4" hex-to-square adapter, 1/4" T-handle and came up with the tap follower solution.

• Once the parts arrived, I opened up the 9th hole to 0.269" (see above) x 10mm deep (the threaded 10-32 holes only needed to be 6mm, but as noted the inserts are 5/16" long), tapped & deburred the 5/16-18 hole, cleaned the hole with Acetone and installed the insert. I then used the workspace to move to the 8th hole, etc. As I installed the inserts, I made sure that they were just below the top of the jaw, using a screw driver to rotate them if necessary (I gently wedged a small screwdriver inside the shortened inserts to rotate them further).

* After all of the inserts had been installed, I opened up the vise, removed the movable jaw. throughly cleaned the guts and reassembled the vise.

For those not familiar with TouchDRO, here is a screenshot of the workspace view:

Yes, I didn't hit the location exactly, but I'm happy with ±0.0006"; also, iGaging SS Absolute Plus scales are only "accurate" to 0.0015".

From this post, I did this:

Started with just drilling holes for 10-32, then changed my mind and went with 10-32 x 5/16-18 inserts (didn't think the 10-32 in the cast steel-ish would last):

The three center holes are shallower to clear the nut. While the outer holes intersect the M6 tapped holes for mounting the jaw plates, the attaching screws only go 8mm deep, so no problems. The 10-32 x 5/16-18 inserts have thin walls, so the outside threads have a shallower profile and require a larger tap drill (E-Z Lok specs an "I" (0.272"), but I crept up on this from an "F" and stopped at 17/64", which gave me 0.269" actual. I tapped the hole (plug & bottom), cleaned the thread locker off of an insert and "offered it up:" it went in easily with no play so I installed the first insert using the E-Z Lok driver bit (not this insert, but it shows the technique):

The driver bit was held in a 1/4" hex-to-square adapter, mounted on a T-handle; the back of the T-handle has a Ø5mm hole, which was almost a perfect fit for the cone-end of my tap follower (see this thread) to keep things reasonably square.

The inserts are 5/16" long, which won't work in a 6.5mm deep hole, but there are no threads at the drive slot, so I faced off the ends of three inserts:

Before & After facing:

And used a nut & SHCS to install the short inserts:

I also added a little extra thread locker, just for insurance.

For those who want to know, here is the sequence of operations I followed:

* Clamped the vise tight, then used an edge finder to locate the center of the moving jaw; moved to the first hole location (upper left), opened the workspace view on TouchDRO and added the first point (ignore the Z-axis location).

• Using a stubby #21 drill bit, touched off on the top of the jaw, zero'd the Z-Axis and drilled 6.5mm deep.

• Moved to the next hole location, added the second point to the workspace, touched off, drilled 6.5mm deep.

* Moved to the third hole location, etc.

* After drilling all of the holes, I tapped the last (9th) hole and ran a 10-32 SHCS in. I wasn't happy with the slightly loose fit, and decided to see what 10-32 inserts were available. McMaster had the 10-32 x 5/16-18 thin-wall inserts, so I ordered two packs of 10, plus a driver. While waiting for the parts to arrive, I dug out the 1/4" hex-to-square adapter, 1/4" T-handle and came up with the tap follower solution.

• Once the parts arrived, I opened up the 9th hole to 0.269" (see above) x 10mm deep (the threaded 10-32 holes only needed to be 6mm, but as noted the inserts are 5/16" long), tapped & deburred the 5/16-18 hole, cleaned the hole with Acetone and installed the insert. I then used the workspace to move to the 8th hole, etc. As I installed the inserts, I made sure that they were just below the top of the jaw, using a screw driver to rotate them if necessary (I gently wedged a small screwdriver inside the shortened inserts to rotate them further).

* After all of the inserts had been installed, I opened up the vise, removed the movable jaw. throughly cleaned the guts and reassembled the vise.

For those not familiar with TouchDRO, here is a screenshot of the workspace view:

Yes, I didn't hit the location exactly, but I'm happy with ±0.0006"; also, iGaging SS Absolute Plus scales are only "accurate" to 0.0015".

Last edited: