ChazzC

Ultra Member

Fix One Issue & Create a New One!

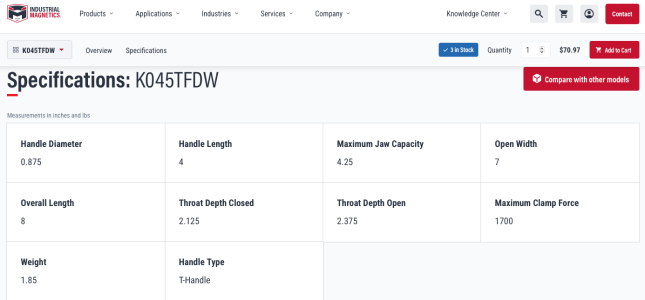

Was very pleased with how the adapter turned out, and it fits on the rotary table much more securely. However, I created another problem opportunity: in reducing the unthreaded portion of the 3/4"-16 hole, I also reduced the width of the wrench flats. I knew that was going to happen, but thought I had a thin open-end or adjustable wrench – wrong. I can get my thin-ish adjustable in just enough to break the adapter free, but it's not good.

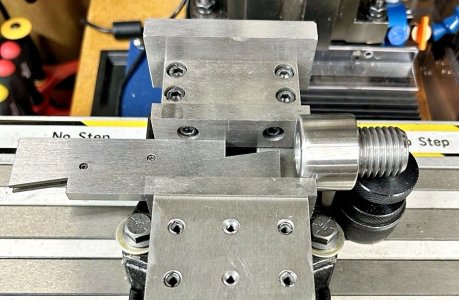

I figured I'd have to buy a thin open-end wrench, but like everyone one on the Forum I dislike acquiring tools. I checked and found that I have a pin C-Wrench that would work, so over to the Mini-Mill, clamping the adapter by its flats and placing an adjustable parallel on the other side of the vise to balance the pressure. Then put a jack under the 1"-8 end to provide support during machining:

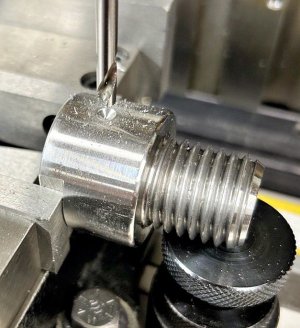

Centered the adapter using a 10mm edge finder:

This edge finder has a ceramic tip and is the only one I have that would reach; I could have centered using the jaws, but didn't trust that the slots were equal (and ended up just rotating the adapter to do the other hole without checking that it was still centered – sometimes I overthink things).

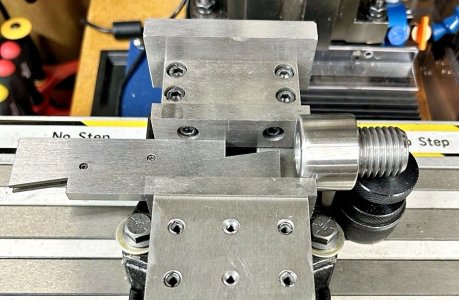

After moving back 15mm from the end of the adapter, I milled a flat using a 2-flute 3/16" end mill:

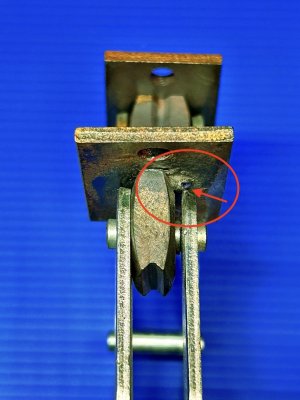

Then drilled 3/16" x 4mm deep to accept the pin wrench (I spot drilled the first hole, then realized that my 3/16" stubby drill bit was shorter than the 3/16" spotting bit, so just drilled the second hole – see, I said I overthink):

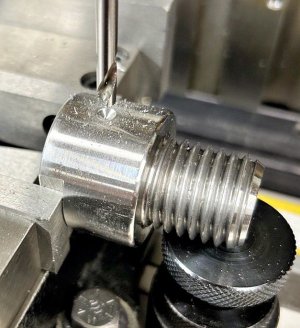

I rotated the adapter in the vise and repeated the milling & drilling. Deburred and cleaned the adapter up, and now it's done:

Was very pleased with how the adapter turned out, and it fits on the rotary table much more securely. However, I created another problem opportunity: in reducing the unthreaded portion of the 3/4"-16 hole, I also reduced the width of the wrench flats. I knew that was going to happen, but thought I had a thin open-end or adjustable wrench – wrong. I can get my thin-ish adjustable in just enough to break the adapter free, but it's not good.

I figured I'd have to buy a thin open-end wrench, but like everyone one on the Forum I dislike acquiring tools. I checked and found that I have a pin C-Wrench that would work, so over to the Mini-Mill, clamping the adapter by its flats and placing an adjustable parallel on the other side of the vise to balance the pressure. Then put a jack under the 1"-8 end to provide support during machining:

Centered the adapter using a 10mm edge finder:

This edge finder has a ceramic tip and is the only one I have that would reach; I could have centered using the jaws, but didn't trust that the slots were equal (and ended up just rotating the adapter to do the other hole without checking that it was still centered – sometimes I overthink things).

After moving back 15mm from the end of the adapter, I milled a flat using a 2-flute 3/16" end mill:

Then drilled 3/16" x 4mm deep to accept the pin wrench (I spot drilled the first hole, then realized that my 3/16" stubby drill bit was shorter than the 3/16" spotting bit, so just drilled the second hole – see, I said I overthink):

I rotated the adapter in the vise and repeated the milling & drilling. Deburred and cleaned the adapter up, and now it's done:

Last edited: