Oh well, if you ain't breaking something occasionally, you ain't learning....😉

It's true, but I much prefer to learn from somebody else's broken stuff.... 😉

Oh well, if you ain't breaking something occasionally, you ain't learning....😉

Got a link to the AliExpress Mesa tool? I like the looks of that. The one's @Susquatch linked to look interesting but just a little too pricey.

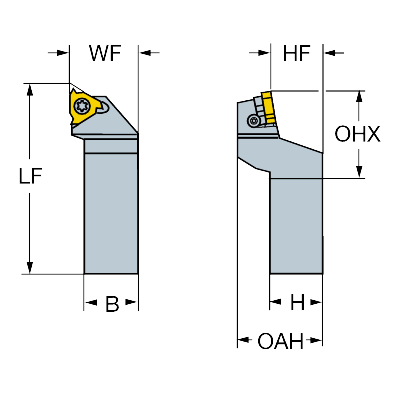

The thing that some folks who operate smaller lathes may experience, which potentially conflicts with the inverted tool method that Joe Pi shows is: the tool post may not accommodate the elevation change of the tool holder + shank. Hopefully sketch makes sense. A thicker body insert holder would be more challenged than a thinner stick of HSS. And like we have discussed before, rotating reverse might conflict with screw on chucks vs his D1-X spindle depending on the cutting load. And not all lathes apparently have independent forward & reverse feed direction? I'm not well versed on that aspect, I only know my own lathe. But ya, if you can start from the recess & run out towards the tail stock, much less knuckle biting adventure disengaging.

Did someone say chuck clamps? Where do I get one of them??? 🙂I don't see what you mean Peter. I see the inverted tool, but what is all that stuff on the LHS of your drawing?

But ya, a threaded on chuck is a problem. One that I'd be trying to solve if that's what I had. My old Reed has a screw on chuck but I doubt you could cut 14 tpi on it let alone 24 or 48.

I thought all you threaded chuck members were drooling over chuck clamps a while back.......

But I feel your pain either way.

Did someone say chuck clamps? Where do I get one of them??? 🙂

I think perhaps your thrifty tongue is in your cheek...... Ya, they are definitely not Ali priced. And as @DPittman suggests, I doubt they are available there. Maybe at a few specialty sellers. I think I recall that Brownells & Midway both sell them. Maybe Grizzly too. They are very popular with precision smith's.

Yes pricey, but IMHO, worth every single penny - especially the HSS Warners. The Warner tool can do what no other threading tool can do. These are HSS Inserts. The LH/RH Inside/Outside capability alone is amazing. Add in the thread size range and the convenience of a pre-ground indexible insert with three working tips. If mine broke, I'd order another one 5 minutes later.

In fact, I like this Warner tool soooo much that I'll make you an offer. Order one. If you don't LOVE it, you can send it to me and I'll give you what you paid for it plus shipping to me.

OK, as @whydontu would say, that is my last dead horse flogging.

For today anyway......

Did someone say chuck clamps? Where do I get one of them??? 🙂

thread startedHere is a link to at least one post on the subject.

Post in thread 'King 1022 $1900' https://canadianhobbymetalworkers.com/threads/king-1022-1900.4355/post-58840

I didn't find anything else. Seems odd to me that would remember the discussion with so few posts. My memory just isn't that good. So I think there must be more.

That said, surely this issue is big enough that it has been solved. There are waaaayy too many really sharp people out there who must have put their brains and talent to the task.

And if not, I vote we start a challenge on the problem to see what all your collective talents can accomplish. I'll happily contribute but my old Reed isn't too likely to be a good test bed.

Anybody else interested in starting a thread on this issue or already know of a good solution?

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

I don't see what you mean Peter. I see the inverted tool, but what is all that stuff on the LHS of your drawing?

Yes for small lathe and threading only, the hss inserts are in my opinion the best way to go. But if you want carbide and/or grooving capabilities the Mesa tool is hard to beat.Ya, I'm sold on the Warners too, but but but..... I'll think on your offer.

Yes for small lathe and threading only the hss inserts are in my opinion the best way to go. But if you want carbide and/or grooving capabilities the Mesa tool is hard to beat.

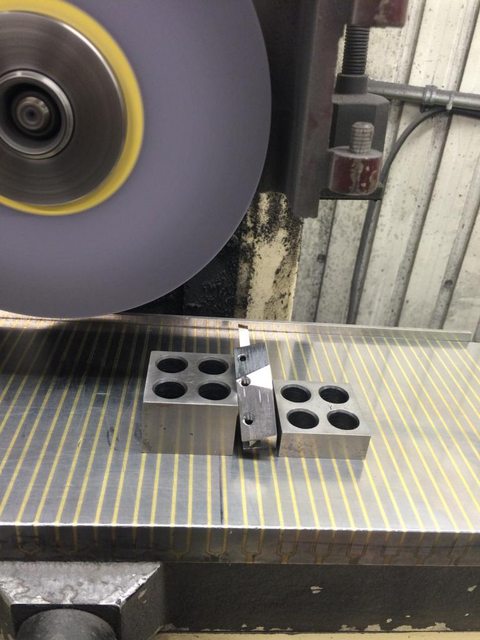

Ya, we've been down the chuck clamp path before. This the clamping 4J I got from @Johnwa (thanks John).

I have been threading in reverse now. Too chicken to try to mimic this arrangement on my 3J back plate though. Maybe if I lucked into an cheap back plate I'd give it a go.

Yup mee 2!Agreed. There is a nice place on the tool shelf I made to mount on my lathe backsplash for both the Mesa and the Warner.

Ya, I'm sold on the Warners too, but but but..... I'll think on your offer.

Of course, if your toolpost doesn't have enough elevation adjustment to mount the tool upside down, then you could always get one of these:The thing that some folks who operate smaller lathes may experience, which potentially conflicts with the inverted tool method that Joe Pi shows is: the tool post may not accommodate the elevation change of the tool holder + shank. Hopefully sketch makes sense. A thicker body insert holder would be more challenged than a thinner stick of HSS. And like we have discussed before, rotating reverse might conflict with screw on chucks vs his D1-X spindle depending on the cutting load. And not all lathes apparently have independent forward & reverse feed direction? I'm not well versed on that aspect, I only know my own lathe. But ya, if you can start from the recess & run out towards the tail stock, much less knuckle biting adventure disengaging.

Was just looking at the warner threading tools and they show inserts with 10 deg. back rake and 0 deg back rake. What would the application be for each?