Yep, I've done both HSS and carbide. Carbide is most convenient / quickest but I've never been happy with the finish - always looks a bit "chattery". I assume its a speed thing. Carbide is by far the most expensive route. I recently bought a kennemetal Left hand holder and inserts ($$) to try Joe Pie's method, video made a lot of sense. Results were kind of disappointing - I could indeed run faster, without fear of crashing - was up to 200 RPM. Finish was still poor though - cutting on the front side, running in reverse, tool upside down, it wanted to lift the (slightly loose) cross slide, causing the chatter. Gotta find a way to tighten that up.🙄

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you guys using for lathe threading tools?

- Thread starter YYCHM

- Start date

Ok, here you go @YYCHM.

These are the only two internal hand ground tool bits I could find. I made the big one from a 5/8 tool bar for really big threads under 10tpi. For smaller threads over 10tpi I used to use the small ones ground from 3/8 tool bar. I know I also made one out of 1/4 tool bar, but I couldn't find it. It may have been repurposed. No matter, I usually use the Mesa or Warner tools instead anyway.

The small one has seen lots of use over the years. I've prolly ground a dozen of them or so just like it. Just no idea where the rest are all hiding. Doesn't matter, these two should address your needs. For teeny tiny internal threads I use a tap just like everyone else. Someday I might try single pointing a #10 screw hole, but that will have to wait until I'm older and wiser....... 😉

One last push for the Warners I posted about above though. They have the ultra convenience of using inserts; the cut quality, low speed performance, and interrupted cut capabilities of HSS; the widest range of compatible thread size of any tool I know; and they do RH/LH external/internal. Worth every penny! 😛

These are the only two internal hand ground tool bits I could find. I made the big one from a 5/8 tool bar for really big threads under 10tpi. For smaller threads over 10tpi I used to use the small ones ground from 3/8 tool bar. I know I also made one out of 1/4 tool bar, but I couldn't find it. It may have been repurposed. No matter, I usually use the Mesa or Warner tools instead anyway.

The small one has seen lots of use over the years. I've prolly ground a dozen of them or so just like it. Just no idea where the rest are all hiding. Doesn't matter, these two should address your needs. For teeny tiny internal threads I use a tap just like everyone else. Someday I might try single pointing a #10 screw hole, but that will have to wait until I'm older and wiser....... 😉

One last push for the Warners I posted about above though. They have the ultra convenience of using inserts; the cut quality, low speed performance, and interrupted cut capabilities of HSS; the widest range of compatible thread size of any tool I know; and they do RH/LH external/internal. Worth every penny! 😛

Hey Craig, I prolly should add that I do a fair bit of SS threading, and often to a shoulder. The orders are slow and easy she goes.... This probably influences my preference for HSS considerably.

I will no doubt get some carbide triangular insert threading tools some day but prolly not till I get more confidence from others. We will see.

I will no doubt get some carbide triangular insert threading tools some day but prolly not till I get more confidence from others. We will see.

I've always wanted to try (but never came across them) those round (as viewed from the side) HSS threading tools. Looks like you could just grind down the top surface to get down to new edges. Top or end view, the 60 degree sides are ground quite a ways around the circumference.

I've always wanted to try (but never came across them) those round (as viewed from the side) HSS threading tools. Looks like you could just grind down the top surface to get down to new edges. Top or end view, the 60 degree sides are ground quite a ways around the circumference.

Not sure what you mean by round????

I routinely sharpen by taking a little off of the top and sometimes off of three sides plus a nick to snub the tip. If you look closely at the small bit posted above, it's had a few cycles of that already.

deleted_user

Super User

I use the Joe Pie method for threading away from the chuck, no rear tool post required. I use the Mesa tool like Sasquatch most of the time but for non 60 degree I hand grind HSS

Joe indeed changed my life with this and his other videos. I used to be paranoid while threading. Especially on our lathe.

DPittman

Ultra Member

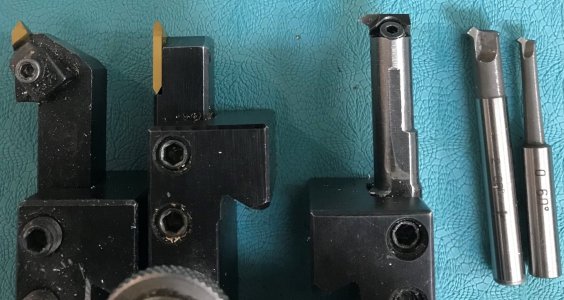

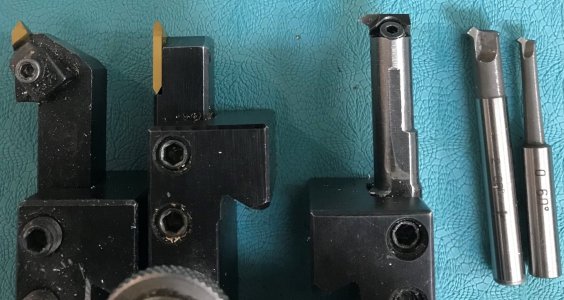

Here a shot of some of the threading tools I use.

The small insert tool is a Warner hss insert and like it.

The little tiny 3/16" square hss bit was for a small internal thread I didn't have a tap for.

And the odd looking one is a 1/4" square hss ground for the eccentric diamond tool holder. I'm not sure it has any big advantages over other styles other than it expands the capability of the diamond tool holder and if you already own one it may save you from buying other tooling.

The second photo shows the Mesa tool threading/grooving insert tool and then a little carbide threading tool (which I haven't yet tried) I bought from Aliexpress. With my little lathe I probably should stick to hss threading tools but the carbide inserts are convenient.

The small insert tool is a Warner hss insert and like it.

The little tiny 3/16" square hss bit was for a small internal thread I didn't have a tap for.

And the odd looking one is a 1/4" square hss ground for the eccentric diamond tool holder. I'm not sure it has any big advantages over other styles other than it expands the capability of the diamond tool holder and if you already own one it may save you from buying other tooling.

The second photo shows the Mesa tool threading/grooving insert tool and then a little carbide threading tool (which I haven't yet tried) I bought from Aliexpress. With my little lathe I probably should stick to hss threading tools but the carbide inserts are convenient.

eotrfish

Ultra Member

Here's my collection of threading tools. I use insert tooling except for tiny internal threads, then I go to the round HSS tools shown on the right.

L to R - Kenametal Top Notch, Nikole Thin-bit, Manchester boring bar, Round tooling - unknown maker

I think the round tooling came from a friend who had a Swiss machine for making dental implants. The beauty of the round tools is that you can regrind the top face as long as your regrind is on axis to the centre line.

L to R - Kenametal Top Notch, Nikole Thin-bit, Manchester boring bar, Round tooling - unknown maker

I think the round tooling came from a friend who had a Swiss machine for making dental implants. The beauty of the round tools is that you can regrind the top face as long as your regrind is on axis to the centre line.

DPittman

Ultra Member

Whoops! That ain't a hss insert in that tool holder. But this one is. Sorry.Here a shot of some of the threading tools I use.

The small insert tool is a Warner hss insert and like it.

The little tiny 3/16" square hss bit was for a small internal thread I didn't have a tap for.

And the odd looking one is a 1/4" square hss ground for the eccentric diamond tool holder. I'm not sure it has any big advantages over other styles other than it expands the capability of the diamond tool holder and if you already own one it may save you from buying other tooling.

The second photo shows the Mesa tool threading/grooving insert tool and then a little carbide threading tool (which I haven't yet tried) I bought from Aliexpress. With my little lathe I probably should stick to hss threading tools but the carbide inserts are convenient. View attachment 20099View attachment 20100

Former Member

Guest

Speeds sorry never gave it much thought when I had too, sorry got good reactions.

As to tooling most of mine until now has been HSS (have carbode now but haven't needed it yet. Consider a small boring bar and grind 1/8" HSS accordingly.

As to tooling most of mine until now has been HSS (have carbode now but haven't needed it yet. Consider a small boring bar and grind 1/8" HSS accordingly.

Six O Two

(Marco)

I tried to grind an internal threading tool once, it wasn't - and still isn't - pretty. I had a lot of problems getting the clearance right on the bottom of the tool and not dragging in the hole. It was very springy also, so I had to make pretty light passes.

For regular threads, I mostly use this inexpensive brazed carbide tool. I've touched it up a few times, and it gets the job done.

For regular threads, I mostly use this inexpensive brazed carbide tool. I've touched it up a few times, and it gets the job done.

Carbide is by far the most expensive route. I recently bought a kennemetal Left hand holder and inserts ($$) to try ...

That's a premium toolholder. Yes I can see that being spendy as would name brand inserts. Just to clarify I'm into my offshore tool holder plus 10 inserts for 20$. It wasn't this particular seller but the combined price was similar. I didn't have high expectations actually, more for curiosity & a touch of laziness. But it wasn't exactly a $ high risk gamble either.

Am I sold on carbide? Yes & No & Maybe So. HSS offers many advantages, I agree with everything said. Some of the most stunning models I've seen never saw carbide for any tooling - threading, turning, milling, drilling... But my view is that turning operations don't begin & end with the cutting tool edge. Lathe / setup / material / geometry / procedure / start-stop / rigidity / fluid ... not only factor but can override success IMO. One guy is talking deep DOC ACME on into tough alloy on a worn out machine with no table locks. Another guy is talking fine threads or maybe confined to brass. Hard to generalize without seeing the full picture & ideally work examples.

Attachments

I think it would help to hold a small tube or bar the same size as the drilled or bored hole that is being threaded, up against the end of the threading tool. You can immediately see where relief is needed and where it is not. It's good to keep as much meat as possible to maximize the tool rigidity without rubbing in the hole.I had a lot of problems getting the clearance right on the bottom of the tool and not dragging in the hole. It was very springy also, so I had to make pretty light passes.

Last edited:

Six O Two

(Marco)

I think it would help to hold a small tube or bar the same size as the drilled or bored hole that is being threaded, up against the end of the threading tool. You can immediately see where relief is needed and where it is not. It's good to keep as much meat as possible to maximize the tool rigidity without rubbing in the hole.

Thanks, that's a great tip!

I guess we both had mishaps yesterday. I jammed a parting tool...ruined the nice knurl I had in the part and damaged my tool holder screw nut. Oh well, if you ain't breaking something occasionally, you ain't learning....😉I never got into threading in reverse away from the chuck, but i'm going to give it a shot. I was making a small drill chuck arbor yesterday and crashed into the shoulder at about 100 rpm cutting the 1/2" 20tpi. Just wasn't quick enough with the half nut and didn't have much of a gutter and as soon as it hit, i couldn't release the half nuts. So now i need to build a rear toolpost.

Other than that, i use a mix of both HSS and carbide insert tooling. HSS is sharper and needs less pressure, so it works better on small diameter, finer thread stuff.

The second photo shows the Mesa tool threading/grooving insert tool and then a little carbide threading tool (which I haven't yet tried) I bought from Aliexpress.

Got a link to the AliExpress Mesa tool? I like the looks of that. The one's @Susquatch linked to look interesting but just a little too pricey.

Last edited:

DPittman

Ultra Member

As far as I know you won't find Mesa tools on Aliexpress. I bought mine directly from Mesa Tool in the USA. Inserts are expensive and are not common or readily available. It seems to me "Nickole" company has similar tooling and some inserts that fit the Mesa Tool but they were even more expensive.Got a link to the AliExpress Mesa tool? I like the looks of that. The one's @Susquatch linked to look interesting but just a little too pricey.

Nikcole Mini-Systems – Niko Nikcole

Machining tools | United States | Cascade Machine Tools

Cascade Machine Tools designs and manufactures tools for the machinist with durability and simplicity in mind. This is a showcase of our products with emphasis on our boring head accessories. You have found the perfect online shop for Boring Bars, Boring Head Accessories, Carbide Inserts...

DPittman

Ultra Member

Oh yeah while you're buying at Mesa Tool you might as well as order yourself one of their boring bars for a boring head, much superior to the brazed carbide ones I've had. The boring bar has a flat spot which allow positive and correct alignment in the boring bar. And it uses common inserts. I'm happy with that purchase also. (And I jest with the idea of just spending money freely and easily...I totally relate to limited budget with hobby spending)

NIKCOLE tools are excellent but also spendy. Most of the inserts are for grooving. I think there is just one standard vee threading insert, good for fine pitches but you'd have to confirm the range.

www.kbctools.ca

www.kbctools.ca

NIKCOLE,MINI-THIN GROOVING & CUT-OFF SET,1-293-015,KBC Tools & Machinery

NIKCOLE,MINI-THIN GROOVING & CUT-OFF SET,1-293-015,KBC Tools & Machinery