Dan Dubeau

Ultra Member

lol. I wish.....Woah! Where did you rent the shop space for that!

LMAO!

lol. I wish.....Woah! Where did you rent the shop space for that!

LMAO!

It was a gaff at your swing typo. 97"!!!lol. I wish.....

Ya, I know. thanks for pointing it out, I corrected it. One side of my brain gets faster than the other when typing sometimes......You should see all the red squiggly lines I gotta fix after I get done typing sometimes. 😀 Never used to be this way, I think my last TBI might have slowed one side down lol. I should probably wear a helmet more often....It was a gaff at your swing typo. 97"!!!

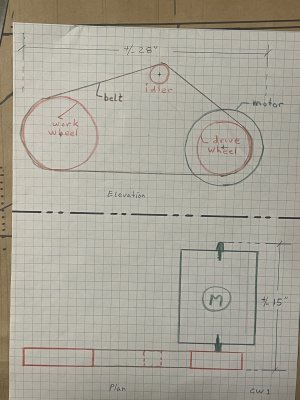

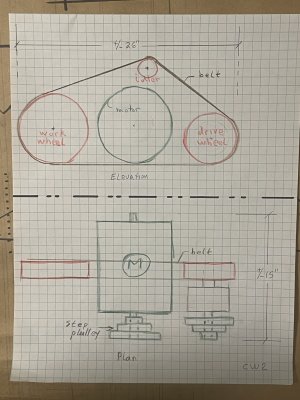

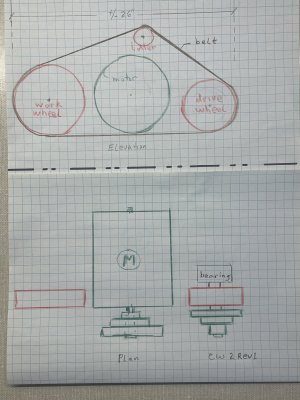

I’d be very interested to hear your thoughts on my concept.

Thanks

Ooops - I had a look. Mine is 1/2Hp (7.8amp). But it sure is big and heavy.

Check motor size requirements. IIRC Jer recommends 5 hp.

i have built 2 2x grinders with, both had 3/4hp. They both worked well, but you could bog either of them without a whole lot of effort......that being said, they still remove metal very very fast with a fresh 36g belt, i dont feel the need for an upgrade, but i also dont make knives

@Dan Dubeau starting this discussion, so IMO moving it to a separate thread is up to him.I still think a new thread is warranted

@Dan Dubeau starting this discussion, so IMO moving it to a separate thread is up to him.

the platen you mean ? its just steel plate (for both), i think thats the most common thing people do, i have it set maybe .5mm behind the back of the belt so there is no additional friction.

both of the ones ive built if you really push hard, like your trying to stall the motor, it just throws the belt, that may be a design flaw, or it may be how all of them behave, im not sure

for what i use it for, mostly deburring, chamfering, sometimes grinding a profile/radius, 3/4hp is enough, it would probably be marginal for some one that wants to make a lot of knives fast (although i did make a few on the first grinder i built). If a 1/2hp motor is what i had, i would build it with 1/2hp and leave enough room for something bigger, at least the option is there if a guy decided he wanted more oomph