-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weiss VM32 CNC Conversion

- Thread starter David

- Start date

In my discussions with Peter he's always either already had a bit file that fits. In my case with the PMDX-126 there were two different bit files. If you use the Gecko G540 there's a bit file for it. The 7i92_C11G series address another group of BoBs.I would think the more likely path is to create your own bit file to map to PathPilot. Peter could help with that.

I have never built a bit file m yselft, instructions are sadly opaque or lacking.

And then there's the more extensive 7i76 series of boards and bit files.

Attached is the VHDL file for creating the .bit file written to the device via mesaflash.

Gosh it's been years since I've done anything with this stuff.

Peter at MESA has always been super helpful.

Attachments

gerritv

Gerrit

I appreciate that Peter is very helpful, I see that on the linuxcnc forums. But somehow being able to build one myself is one of those strange needs, an itch that pops up now and then. Not that I need a custom one right now but......

With PathPilot in particular, I think your goal should be pin compatible. Even with a custom bitfile if necessary. Otherwise you are in for a world of work everytime they do an update. You would need to compare your hal and ini files with their new ones. Not that they change often but 3.0 is coming eventually. I opted to make a jumble cable to match the 1100-3 bit file which leaves me with only 4 or 5 lines to update each time.

Keep in mind that Tormach actively supports PathPilot, they issued 40+ updates so far on 2.0 since Dec 2017.

With PathPilot in particular, I think your goal should be pin compatible. Even with a custom bitfile if necessary. Otherwise you are in for a world of work everytime they do an update. You would need to compare your hal and ini files with their new ones. Not that they change often but 3.0 is coming eventually. I opted to make a jumble cable to match the 1100-3 bit file which leaves me with only 4 or 5 lines to update each time.

Keep in mind that Tormach actively supports PathPilot, they issued 40+ updates so far on 2.0 since Dec 2017.

Last edited:

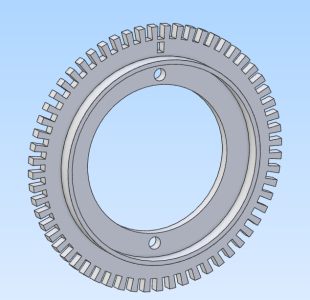

3D Printed?In anticipation of having rigid tapping available via Linux CNC I made an encoder ring.

View attachment 65195

So you don't go through the anguish I did I'll let you know up front that you will have to paint them with a metalized paint.

The encoder disk in this photo is actually also 3D printed.

The trouble is the PLA is transparent to IR from the optical sensors. I found that out the hard way.

Good to know!3D Printed?

So you don't go through the anguish I did I'll let you know up front that you will have to paint them with a metalized paint.

The encoder disk in this photo is actually also 3D printed.

View attachment 65202

The trouble is the PLA is transparent to IR from the optical sensors. I found that out the hard way.

Maybe I'll chrome plate it 😀

Yes. Will need an index slot too.Does it have an index slot in it? I think it needs that for tapping.

On my Emco lathe, it just has an extra deep slot. Don't know if lcnc is picky about placement but I suspect not as the placement of the sensor would also need to be spaced exactly as well if the signals needed to be at the same time, and I just slapped my sensors in. I either have a great deal of luck or it doesn't care.

Or not. Never mind, brain is turning off for the night.

Or not. Never mind, brain is turning off for the night.

slow-poke

Ultra Member

I'm kinda partial to the Omron and even the knockoff Omkon encoders. High resolution and seem to last.

Sometimes actual Omrons show up on ebay for cheap, I scored some for $20. They are expensive from DK....

www.digikey.ca

www.digikey.ca

600P/R Rotary Encoder, Aideepen AB 2 Phase Incremental Rotary Encoder 6mm Shaft 5V-24V Wide Voltage : Amazon.ca: Industrial & Scientific

600P/R Rotary Encoder, Aideepen AB 2 Phase Incremental Rotary Encoder 6mm Shaft 5V-24V Wide Voltage : Amazon.ca: Industrial & Scientific

www.amazon.ca

Sometimes actual Omrons show up on ebay for cheap, I scored some for $20. They are expensive from DK....

E6B2-CWZ1X 600P/R 2M | DigiKey Electronics

Order Omron Automation and Safety E6B2-CWZ1X 600P/R 2M (E6B2-CWZ1X600P/R2M-ND) at DigiKey. Check stock and pricing, view product specifications, and order online.

Last edited:

I'm hoping to avoid a rotary encoder simply because of the extra faffing with mounts, pulleys and belts but it may be a moot because I need to fabricobble a sensor for the ring. Maybe rotary is the way to go as my electronics skills are well, non-existent.

Last edited:

slow-poke

Ultra Member

Fairly easy to 3D print a mounting bracket and pulleys to match any tiny timing belt you have laying around. 3D printers have small belts that are appropriate. Food for thought.I'm hoping to avoid a rotary encoder simply because of the extra faffing about but it may be a moot because I need to fabricobble a sensor for the ring. Maybe rotary is the way to go?

Last edited:

I likely have GT3 belts and pulleys. Wonder if I could 3D print a pulley that would slip over the top of the spindle....Fairly easy to 3D print a mounting bracket then any tiny timing belt you have laying around. Food for thought.

slow-poke

Ultra Member

That's what I did. Timing pulley 3D models are plentiful via Google search.I likely have GT3 belts and pulleys. Wonder if I could 3D print a pulley that would slip over the top of the spindle....