-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weiss VM32 CNC Conversion

- Thread starter David

- Start date

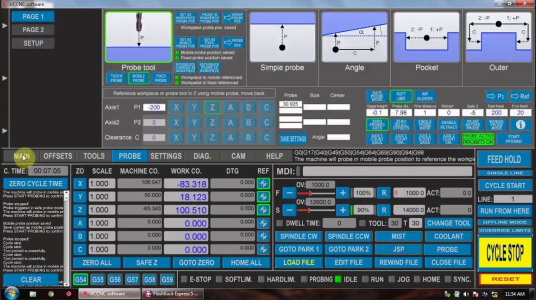

Yes. I've smashed one probe unit and bent the touch pin. The trouble is when you have a fast speed of 200 IPM and it decides to use that to get to the probing part which is for some reason higher than where the probe is the collision is quite spectacular and there's no time to hit an ESTOP. Really should change all probe operations to F20 or something.Confusing probing routines are why I'm on my 3rd probe! Got to say the Path Pilot routines are not confusing (thankfully!) and hence the relative longevity of my current touch probe

Yeah, you need to make sure the probe tip is going to be the part to contact an immoveable object first, not the probe body. This also applies in Z direction and not just X-Y - such as probing a surface that has a hole directly under the probe tip...Its painful watching it get crushed just a millisecond before hitting the e-stop!

Calibrated the X and Y axis tonight after making sure all the ball screw couplers and gibs were snug.

Backlash on the Y was .06mm and on the X was .1mm which is pretty respectable and well within the backlash compensation limits of the software.

Managed to get both X and Y to repeat to 0.00mm or .01mm in both positive and negative directions.

I call that a major win

Backlash on the Y was .06mm and on the X was .1mm which is pretty respectable and well within the backlash compensation limits of the software.

Managed to get both X and Y to repeat to 0.00mm or .01mm in both positive and negative directions.

I call that a major win

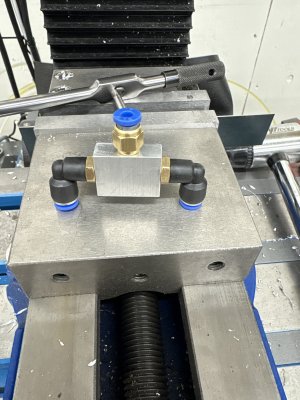

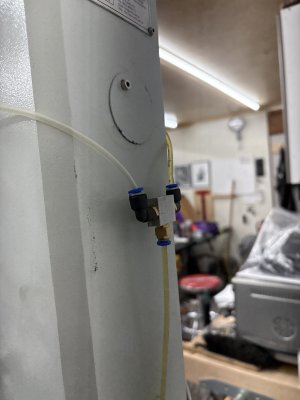

Hmmmmm. Looks like there's even oil in it.Oil system almost done.

X and Y axis are done. I’m lacking a 4mm T fitting to do the Z. I hope Newline has one.

View attachment 61835

And the problem with is???? LOLHobby metal workers - folks who will spend 3 hours of time and $25 worth of material and cutters to make a $6.15 fitting.

140mower

Don

It's what we do...... And, I think, mostly we do it because the rest of them can't.....🙄😛Hobby metal workers - folks who will spend 3 hours of time and $25 worth of material and cutters to make a $6.15 fitting.

View attachment 61838

I work for food 🙂I wonder if anyone would notice if I came down and kidnapped you for a week or so, you could probably catch me up on 43 of my 42 projects..... 🙄 😛

He's been spoiled now. Of course this was baby steps using the MPG. Not real CAD/CAM...One T manifold made on the mill using the MPG for movement. Works like a hot damn.

View attachment 61841

I know, I know.... I hope to try an actual CAD/CAM project tomorrow 🙂He's been spoiled now. Of course this was baby steps using the MPG. Not real CAD/CAM...