Since you guys are going deep into the VFD world…..

Setting up the programming:

Max Voltage: 220 V for typical motor

Reference Frequency: 60 Hz for our motors or 50 Hz for Euro

Intermediate Voltage - default is 110 - What is this? Appears to be just half the motor max voltage but does it have a purpose?

Intermediate frequency: 25 Hz is default- again what is this? It is half the working frequency- does it have a purpose for adjustment?

Minimum voltage: 0 - what does increasing it do?

Minimum frequency: 0 - what does increasing it do?

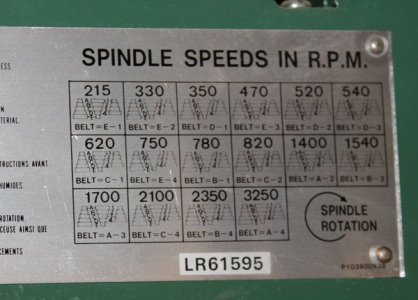

Maximum operating Frequency: default is 65 but could be set to yield your maximum desired RPM.

Minimum Operating Frequency: 0 default but could be set for your slowest RPM.

There are tons of codes you can program- any ones that should be fixed up? or that there is a benefit to changing? - Working frequency, revolution for 50 Hz for example.

Hi Brent. My manual is useless on all those questions. I played with them anyway. One of my many character flaws I guess...

What I discovered is that they DON'T do the obvious. Some of them seem to make no difference. Others totally screw up sensorless vector mode - not good. Still others cause the motor to not spin up properly on its own.

I ended up resetting to factory and starting over leaving all of those alone. But even this is a problem because factory default is NOT what they say it is. So I had to painstakingly go through everything.

If you decide to play with them, keep a log so you can reverse whatever you did. But I'm not really sure that works because some settings change others and then don't reverse when you change them back.

I'm still waiting for a call back on auto tuning function. The tech I spoke to couldn't get his head around "yes it works but I want it to work optimally". He wanted to close the file the moment I said it works. Obviously not wired the way that I am.

I opened Pandora's box when

@Dabbler convinced me to get a VFD. Now I wanna know what else is in that box..... LOL!

If you have a TECO, here are my current settings. They do work great.

Set 00-00 from 0 to 1 - Sensorless Vector Mode

Set 00-02 from 0 to 1 - use external switch for R/S & Attach SPDT switch to common, S1, & S2

Set 00-05 from 0 to 1 - External Potentiometer & Attach 2K pot to 10V, Gnd, and AVI (Ctr to AVI)

Note - my VFD Recommends 5K pot but other ranges will work. I didn't have a 5k so I ordered one and used a cheap 10k in the meantime.

Set 11-01 from 5k to 16k - Carrier Frequency - I am currently set to 12k

Set 11-02 from 1 to 0 - 3ph modulation - Required for Sensorless vector mode

Set 00-12 from 60 to 120 - upper freq limit

Set 00-13 from 0 to 5.0 - lower freq limit

Set 00-14 from 10 to 5 - accell time in seconds

Set 00-15 from 10 to 5 - decell time in seconds

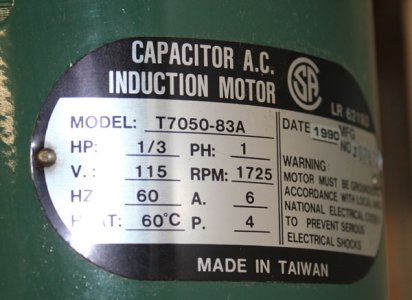

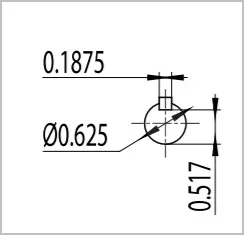

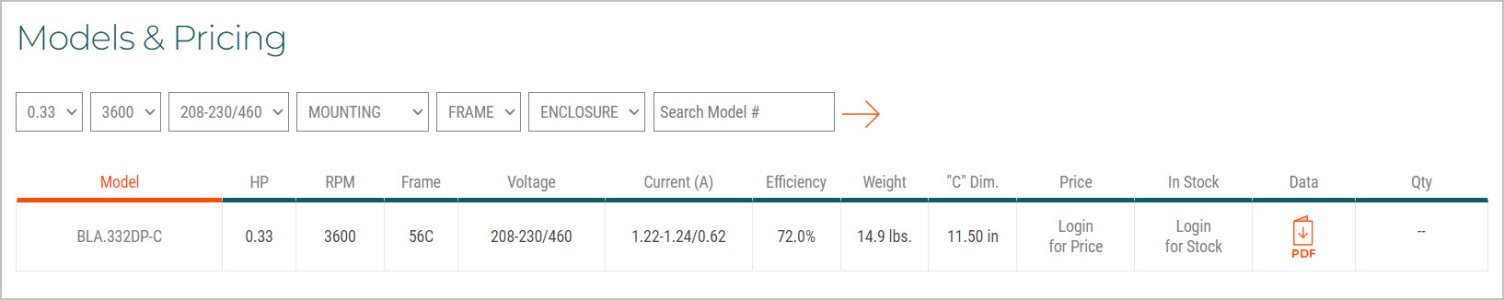

I did not change motor settings (voltage, current, freq, etc) changing them made things work oddly. Leaving them at factory worked fine. I think the VFD figures out what they should be via the current and voltage feedback loop, and that works better than telling the VFD what they are.

Note that I have a VFD rated 1000:1 motor (0 to 120hz)

Maybe include the following later on if motor heating becomes a problem. (no problems so far at)

Setup Cooling fan to run below 30 hz and Use the relay on RA & RB then:

Set 03-11 from 1 to 5 - on when output below

Set 03-12 from 0 to 30 - 30Hz switch point