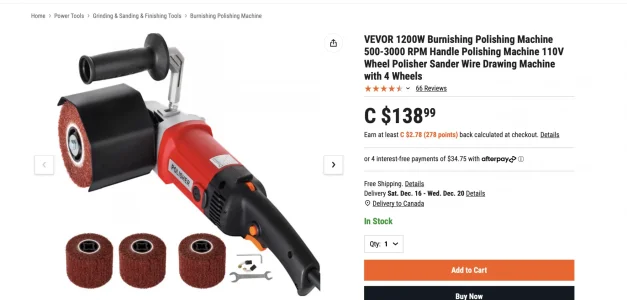

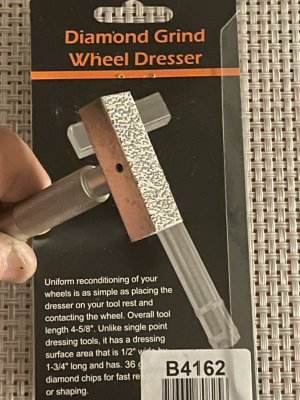

Is this a tool I actually want? I just watched a youtube video commercial (ah hem I mean review) for one of those Vevor deals - this time a burnishing machine. It looks pretty appealing on the never quite solved removing mill scale problem. Cleaning up sheet metal and stock for welding and painting is what I'm interested in. I'm not going to post links to that commercial. Does anybody actually have one? The Vevor one I mean. I've seen other brands which seem like premium tools and premium priced so I never considered it. How long do the wheels last? Do they just load up and stop working? Is it faster than using a grinder which I loathe?. If anybody has experience with the vevor one or anything else similar please comment.