Nope, we are still not connecting.

What you just described is almost EXACTLY what I suggested and was quite comfortable with. The only major difference is that you only focussed on distortion in the axial direction and I could easily see other forces experiencing similar changes.

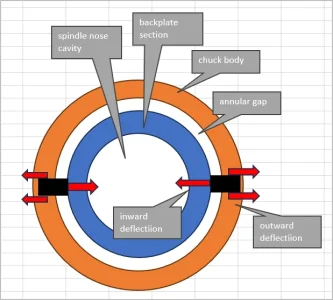

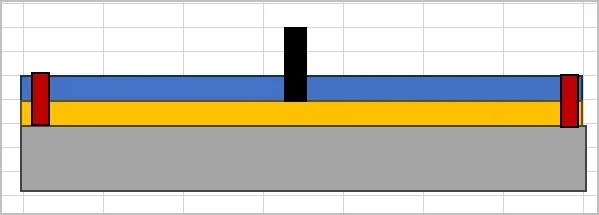

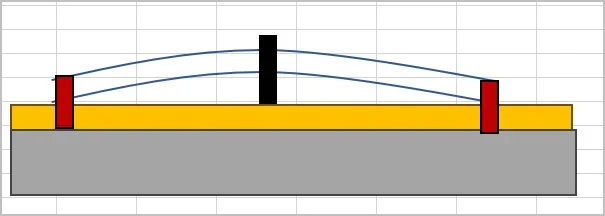

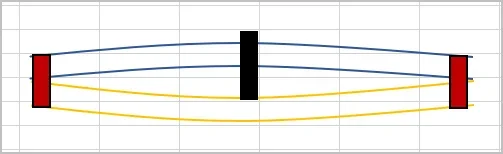

Now I could theoretically force the beams back as they were, conform the yellow to flat earth again & it would look like middle picture within elastic limits. But now the analogy is getting a bit weird because we are talking about a no longer round tapered socket (backplate) socket trying to fit a round tapered spindle nose, being sucked in by camlocks....

Theoretically yes, but not in reality. As you describe, the no longer round socket and other dimensional changes will supply friction that did not exist during the the pre-balanced condition. These friction forces will generate hysteresis in the forces and resulting flecture of the parts. No matter how solidly you mount the backplate, this friction induced stress will result in distortion of the re-installed chuck that wasn't there when it was first installed with loose jack screws.

As I mentioned previously, you will have to mount the chuck several times to evaluate this because the first cycle is not the same as subsequent cycles.

In your second last description, you said:

Why wouldn't the backplate also be free to distort to some degree over time?

It was your comment, "over time" that I didn't agree with, not your overall theory. I frankly think your theory is bang on albeit only focussed on one variable when there are many. Hence my eager willingness to bet a coffee to be consumed in Chatham.

I also wish to acknowledge that

@RobinHood pointed out this very issue in his very first post albeit not calling it hysteresis.

On the 5C chuck, was it removed and remounted to the spindle during the timeframe where it “drifted” out of concentricity? We know the 6J was removed.

If it was taken off and put back on the spindle, my bet is on the backing plate taper engaging too heavily before it is drawn completely onto the flange - thus distorting the plate (or, the taper may be too loose).

Then he proceeded to throw us all off by diving into cam-lock tightening sequence! LOL!

No matter how carefully you mount the chuck, it is near impossible to put the exact same force on the same cams in the same sequence from one time to the next.

I believe that different preconditions, that result in different friction, causing hysteresis, is the bigger culprit here.

I think it's also worth noting here that there are other forces that really do include such meager forces as

@trevj suggests:

You missed whether you put a hot cuppa, on the headstock, as well as whether you placed your hand on the lathe while the measurements were taken. Depending on how the lathe is secured, and to what, also where you were standing, when the measurements were taken.

Only mostly, tongue in cheek, as I have seen instrumentation that could measure the little wee differences.

I won't refer to Gotteswinter's or Renzetti's rubber cuz it's not my saying, but will instead repeat my own version which I have said many many times on here - long before I first heard theirs. "

Absolutely everything moves (no matter how big or strong) in response to applied forces (no matter how small) - it isn't if, it's only how much and does it matter."

In conclusion, I think we are done here Peter. Great job as usual.

I'd happily pay you to teach me to use Fusion as effortlessly as you do. I am soooooo jealous!