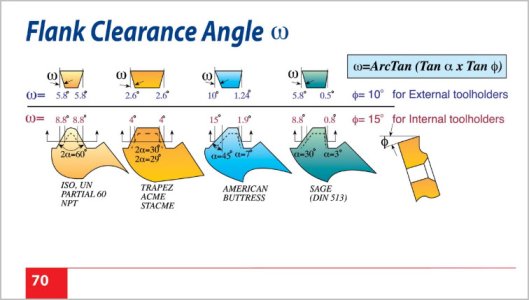

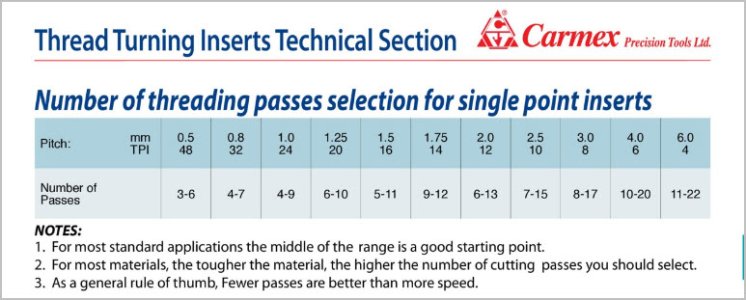

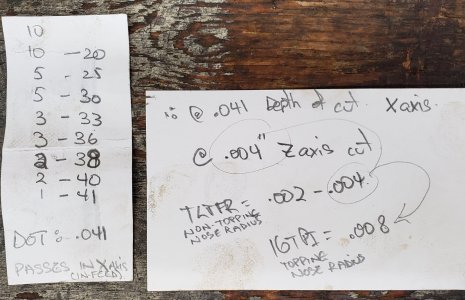

@Susquatch: Please refer to the attachments for your reading pleasure. There are "preferences" for how you set up and make threads, and indeed there are many different threads that are cut and the profile of the thread required will possibly dictate what set up is required. clearance for the tool, load, chip removal etc etc will typically dictate what is necessary for proper threading.

This was worth its weight in gold to me

@Brent H.

I found two things of great significance to my quest in your documents.

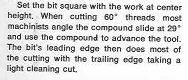

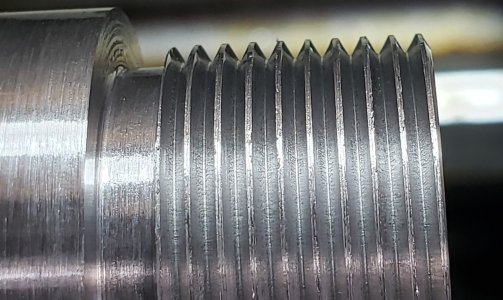

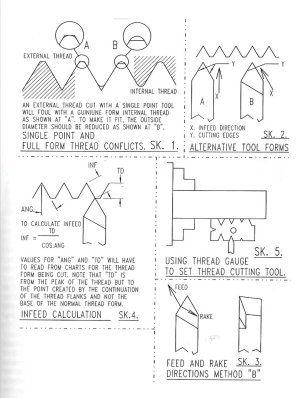

In the first document, the author describes how we arrived at 29 vs 30. Basically he confirms what I had surmised earlier. On the earliest lathes it was not practical to set a precise angle of 30 degrees to cut perfect threads. But it was soon discovered that 29 degrees didn't need to be precise. 29 degrees solved the problem of precision by cutting the majority of the work on the leading face of the cutter and cleaning up the remainder on the right face with a very light 1 degree progressively deeper cleanup pass on the right face.

As

@Dabbler said, a precise 30 works just fine. But 30.2 would not. In the absence of an easy way to set angles, machinists just fell into the practice of using 29.5 (or at least some slight angle less than 30).

The second source contains a reference section with information in it that I have never seen before. I "believe" it points to the reason for doing the 30 degree compound cut.

It is buried in the attached screen shot and discussed in the text.

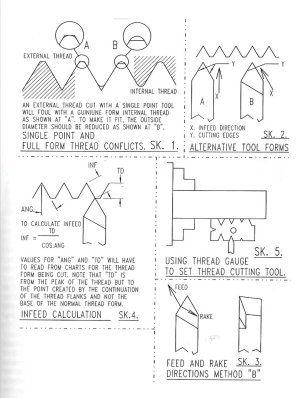

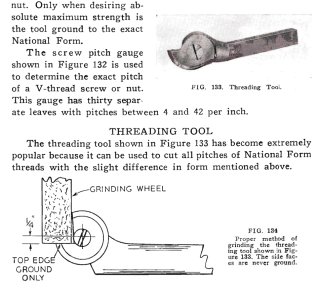

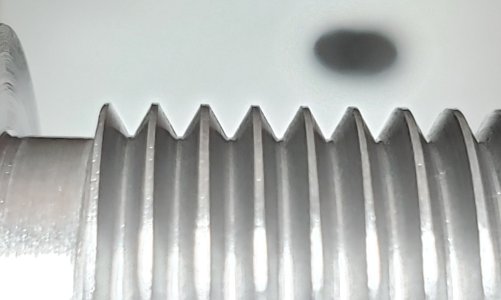

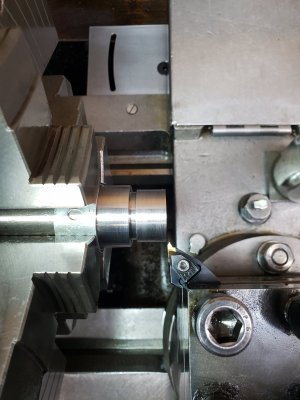

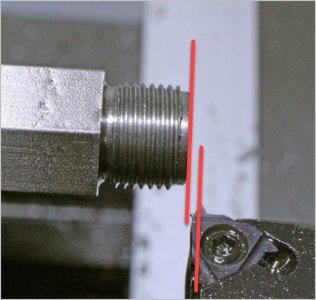

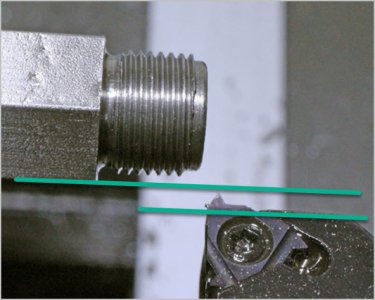

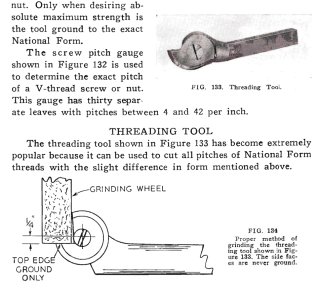

Note the top rake on the cutting tool used for 30 degree method vs 90 degree in the top right drawing. The author claims that a single point tool that cuts on both faces must be flat with no rake and this results in chip clogging in many cases. A double rake tool is not possible with conventional grinding methods of that time. However, a tool with a top edge ground to cut primarily on the left edge never does this.

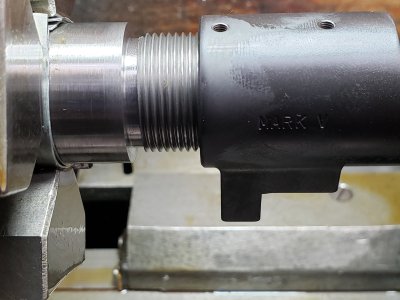

It is worth remembering the old lantern style threading tools of the day.

One can, easily imagine the process of cutting even moderate threads with a lantern post tool like that on an old lathe like my 1800s FE Reed.

At this point I can only speculate about a few things. Having done business in other parts of the world, I can say with certainty that there are many industrial practices in the old world and the new that were driven by the two world wars and especially the second world war.

I have almost no difficulty imagining that machine Shop practices on North America would survive the wars virtually intact. Old school (old lathes) machinists would teach the new machinists in the old school ways and that craftsmanship would stay engrained in machining practices regardless of changes in the machines and tools. Where once there was a reason for 30 degrees, the practice would continue even as the reason itself disappeared.

In the old world which had to be largely rebuilt from the ground up after the war ended, new machines, new tooling, and new practices would easily take hold.

Imagine then the arrival of carbide and multi-point threading tooling with none of the limitations of lantern style thread tooling and it is relatively easy for me to speculate about

@Mcgyver s different shade of grey in the old world vs the new.

I don't personally believe that we are likely to find clear evidence to support or refute the speculation above. So I am ready to let it go (for now).

Nonetheless, there are some good outcomes from this exercise.

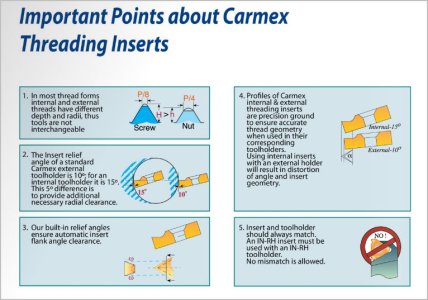

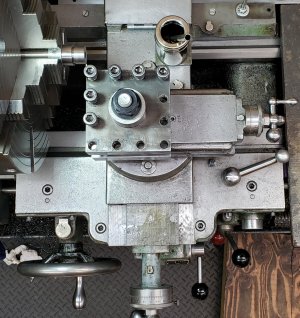

There are times and situations where both processes are advantageous. And while small modern machines are not as robust as new industrial machines, they are certainly orders of magnitude better than the old lantern style lathes that predominated before and after the wars. I believe in my heart of hearts that there is lots of room for both methods in any hobbiest workshop. Furthermore, I believe that learning from history is the best way to avoid repeating its negatives.

I am looking forward to learning to plunge thread and may even go buy some inserts to further facilitate that!

Although I will always be open to alternative explanations with or without evidence, I wish to extend a big huge thank you to everyone for ringing in and especially to

@Brent H and his library for helping me bring this to a good comfortable conclusion in my own mind.