Edit: I think I know what you mean now after thinking about it.

I don't😕 Explain it to me now please. I probably don't appreciate what kind of tool you need.

Edit: I think I know what you mean now after thinking about it.

I need a form tool that cuts this shape in the end of a 5/8" rod.I don't😕 Explain it to me now please. I probably don't appreciate what kind of tool you need.

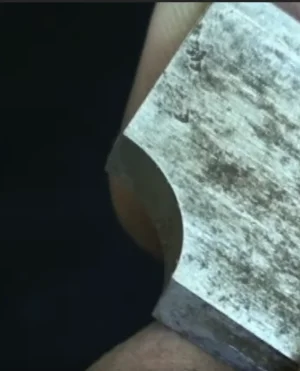

I need a form tool that cuts this shape in the end of a 5/8" rod.

View attachment 14196

@RobinHood is suggesting that I put a ball nose endmill in a boring bar holder and use it to form the radius on the rod by moving the Z and X axis

It's for the floating vise handle.

I need to put the radius on the part with the pin.

View attachment 14197

Like I need another project!Time to make a ball turning attachment for your lathe.

it is very easy to do on your mill, not your lathe.

Hello,

I'm still new here, so I will start reading this thread for its long history.

I'm having a TLDR moment with this thread, but I'll get over it because there's probably some gems hiding in here.

Before I dive into reading this whole (long) thread, is there a summary somewhere that I can use?

For work, I need to source materials and processes as well (laser cutting, anodizing, composite bonding, etc) and I 'd like to find out when new players enter or leave the field (in Alberta especially).

Suggestion: Anybody compiling a Google sheet? Does on already exist? Looks like a big enough audience here for that to be very valuable.