terry_g

Ultra Member

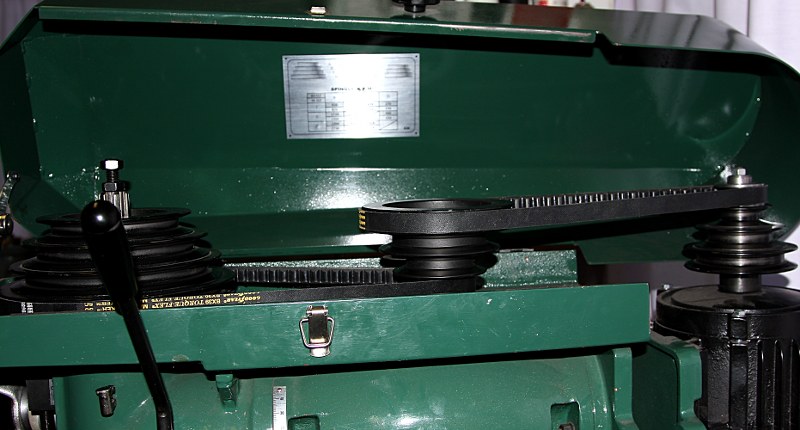

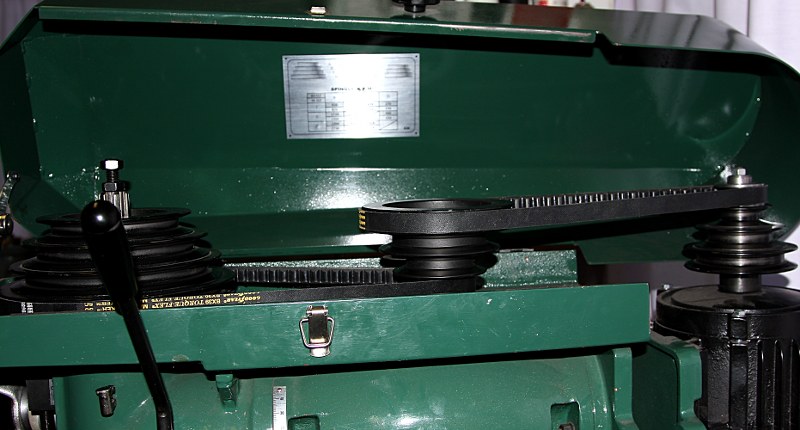

I made a pulley that would fit into the top of the cone pulley on the motor to give me a slower speed

160 rpm the lowest with the factory setup was 270 rpm.

Assemble these parts.

You will have this.

Slide it into the cone pulley and tighten the nut.

A shorter belt was required.

There is a wide space in the speeds in the middle between 490 rpm to 950 rpm.

By running a belt directly from the motor to the spindle pulley I was able to get 660 rpm.

160 rpm the lowest with the factory setup was 270 rpm.

Assemble these parts.

You will have this.

Slide it into the cone pulley and tighten the nut.

A shorter belt was required.

There is a wide space in the speeds in the middle between 490 rpm to 950 rpm.

By running a belt directly from the motor to the spindle pulley I was able to get 660 rpm.