DPittman

Ultra Member

Why not? I would.What are you gunna do when it's a bull barrel and a 17 caliber hole?

I know, nobody is ever gunna want that

Why not? I would.What are you gunna do when it's a bull barrel and a 17 caliber hole?

I know, nobody is ever gunna want that

Well, that was almost an 1" in diameter, and I think 30 caliber. And there was enough cutter surface to go wider, so I don't think it'll be an issue.That's a pretty wide cut to do all at once... What are you gunna do when it's a bull barrel and a 17 caliber hole?

I know, nobody is ever gunna want that, it's only worst case. But there will be a few who want a 224 hole in a bull barrel.

Why not? I would.

Well, that was almost an 1" in diameter, and I think 30 caliber. And there was enough cutter surface to go wider, so I don't think it'll be an issue.

He'll need a gun bearer or golf cart!That's a lot wider than it looks. But ok. If it works it works!

Btw, apparently @DPittman wants one in 17 cal.......

I wanna watch to see how far he can carry it..... 😉

No problem from the house to the cab of the truck and then out of there maybe 10 yards and then back again! The weight slows down my shakes.I wanna watch to see how far he can carry it..... 😉

I ordered it from McMaster.I dont dare ask what that cast iron slug cost?!

For those of you with a business account. Us poor minions do not have that luxury, Sigh!I ordered it from McMaster.

If you have done all the right things and still broken a blade you need this. Parting is the rigidity test for any lathe. Especially when parting something recalcitrant like stainless or aluminumThis is on my to do list too. My lathe is not so little and is probably just fine as is, but more is better when the operator isn't the best tool in the cabinet.

I mostly need help with parting. It's not that I can't part, it's just that it's almost never a painless activity, and I know I can do better so why not try. A dedicated parting plinth just seems so obvious so why not! @thestelster is my inspiration this time around, but @Dabbler has inspired me in the past. This project keeps moving up my priority list.

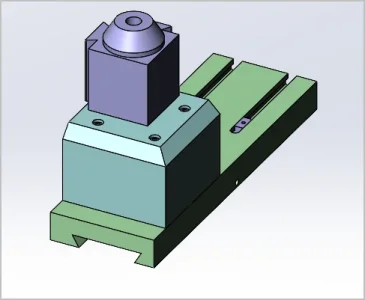

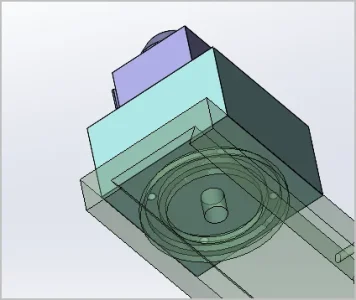

I'm thinking a plinth to replace the entire tool post with a dedicated 1" blade holder built right into it. At this time, the only real challenge is setting spindle center. Adjustments reduce rigidity, so I'd like to get around that somehow without losing the flexibility of being able to use various blades.

If you have done all the right things and still broken a blade you need this. Parting is the rigidity test for any lathe. Especially when parting something recalcitrant like stainless or aluminum

Because????Well, it's been a little over a year since going to a solid toolpost/plinth like so many of the YouTube machinist gurus/charlatans.

I decided to switch back.

I will try straight on threading instead of 29 degrees.

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com