pdentrem

Ultra Member

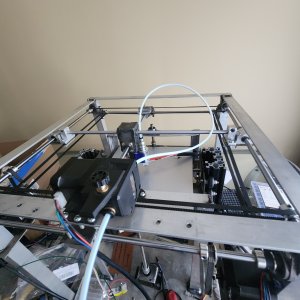

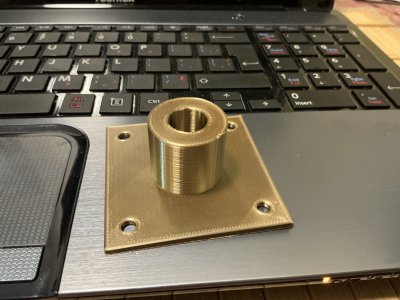

First look at the stored and travel set up of the telescope. Overall height of 13.5”. Sweet! The upper section fits nicely over the lower with lots of room for the secondary mirror to clear.

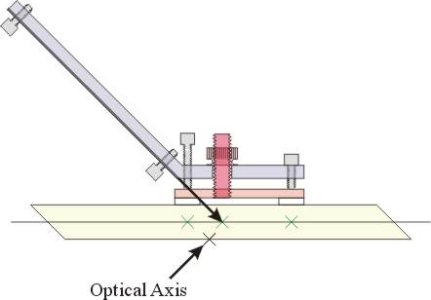

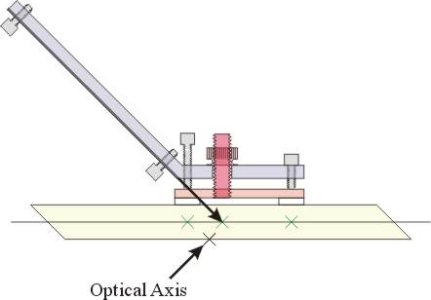

Still have to make secondary support bits and measure for the CF tubes for the trusses. The trusses are represented by the third photo of another persons build.

Pierre

Still have to make secondary support bits and measure for the CF tubes for the trusses. The trusses are represented by the third photo of another persons build.

Pierre