-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So I've jumped into the rabbit hole

- Thread starter Dabbler

- Start date

pdentrem

Ultra Member

Started making a dry box based upon a couple YouTube videos. At the moment, I only testing the power system. While testing, why not start drying the two open spools of filament! Next to print the tube support brackets and install the tubing to transfer the filament to the printer.

Pierre

Pierre

Dan Dubeau

Ultra Member

It's going to be a really dry hamster.Ok, at first glance i thought you bought a hamster.

BaitMaster

Ultra Member

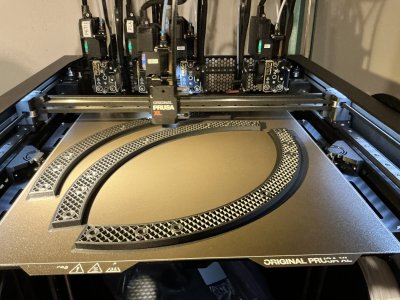

That Multi headed prusa XL is EPIC man. printer envy.

Just look at that printer! @pdentrem have you done any mixed diameter nozzle prints, say 0.8mm for coarse fast areas, and a 0.4mm for threads and lettering etc. How does that work out?Tonight’s print job. Finalized the design and this will make 6 of the 8 sectors needed to make the two rings on the upper section of the telescope.

Pierre

View attachment 55139

How are you using the multiple heads in practice?

Tom O

Ultra Member

I got this in my mail today it’s one of those stay tuned to preorder but could be interesting.

Maybe this?

Maybe this?

I'd make sure it takes standard rolls. As far as I understand it, the Bambu doesn't take standard size rolls.

Maybe @jcdammeyer can weigh in on this.

Maybe @jcdammeyer can weigh in on this.

Doggggboy

Ultra Member

Bambu takes standard rolls.I'd make sure it takes standard rolls. As far as I understand it, the Bambu doesn't take standard size rolls.

Maybe @jcdammeyer can weigh in on this.

I stand corrected, I think @jcdammeyer was having issues because of cardboard rolls from Matter3D which were also very full so they interfered with the guides.Bambu takes standard rolls.

Doggggboy

Ultra Member

That can happen with the AMS (the multiple spool handler)I stand corrected, I think @jcdammeyer was having issues because of cardboard rolls from Matter3D which were also very full so they interfered with the guides.

Any oversize spool can just be mounted on the back of the printer. This also needs to be done with TPU filament.

Sometimes the AMS has trouble rewinding the cardboard spools when retracting the filament, mostly when the spool is almost empty and too light to be spun properly by the rollers under the spool.

OK. I've had BadaBambu now for a week. I've gone through 4 spools of filament already including reprinting two pieces but this time using the support filament which is only used as a thin layer between the actual printing PLA. Mostly the issue with the support filament doing curves that arc upwards is lots of swapping filament back and forth. This is where a multi-extruder unit would be more effective.I stand corrected, I think @jcdammeyer was having issues because of cardboard rolls from Matter3D which were also very full so they interfered with the guides.

What I like most about the Bambu X1C though is that the bed doesn't move back and forth and so the XY motion is so much faster and smoother. What takes 2 hours on the SOVOL takes half that time on the Bambu.

The surface finish on a piece that was supported is simply amazing compared to the old way of doing it with the same filament. Amazon is supposed to deliver the 5mm diameter magnets today so I can put those into both the frame and the doors and then use them to correctly position everything when I glue the frame together.

I haven't decided yet if I want to use the 4xRed_1xBlue LED tape or the led strip with the REDish Blue LEDs for the grow light trays.

Also not yet decided on the plant probes and auto watering system.

Edit: It's 16"x10"x24"

Last edited:

And forgot to answer @DavidR8 question about spools. Bambu states that the cardboard spools can leave dust that eventually jams up the rollers. The latest filament I got from Matter3D in Langford is meant for Bambu so has a plastic spool at an adder of an extra $0.5 I think. But they'll refill the rolls so only really pay for it once.

After I figured out how to use non-Bambu RFID rolls that issue with loading a full plastic Bambu roll went away although they are noisier than the Bambu rolls. Last night at about 1:30AM my phone told me the 4th roll that I was using for a long print was empty. I went down, pulled out the empty one, installed a fresh new Matter3D roll and pressed OK. It loaded and then went on printing.

My SOVOL also stops but I've not set anything up with OctoPrint to let me know that it needs a filament change. I also get more spiderwebbing from the SOVOL. Not sure why.

After I figured out how to use non-Bambu RFID rolls that issue with loading a full plastic Bambu roll went away although they are noisier than the Bambu rolls. Last night at about 1:30AM my phone told me the 4th roll that I was using for a long print was empty. I went down, pulled out the empty one, installed a fresh new Matter3D roll and pressed OK. It loaded and then went on printing.

My SOVOL also stops but I've not set anything up with OctoPrint to let me know that it needs a filament change. I also get more spiderwebbing from the SOVOL. Not sure why.

Haven't watched all of this but so far it's interesting. All about support materials.