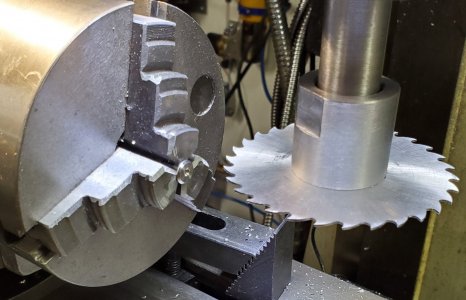

When tightened down the machine screw head is flush with the bottom of the arbor. I could possibly counter sink it a bit more and thin that bottom piece but there's not much to gain. I can't remember what I did exactly but it only protrudes about 1/8 to 3/16 below the blade when screwed down..To my eye, it looks like you could lose the washer and recess/countersink the entire machine screw head to gain clearance below the saw blade.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Slitting Saw Holder

- Thread starter jcdammeyer

- Start date

Tool

When tightened down the machine screw head is flush with the bottom of the arbor. I could possibly counter sink it a bit more and thin that bottom piece but there's not much to gain. I can't remember what I did exactly but it only protrudes about 1/8 to 3/16 below the blade when screwed down..

I see. That's not obvious in the photo.

I might be tempted to taper it instead of making it thinner.

ChazzC

Ultra Member

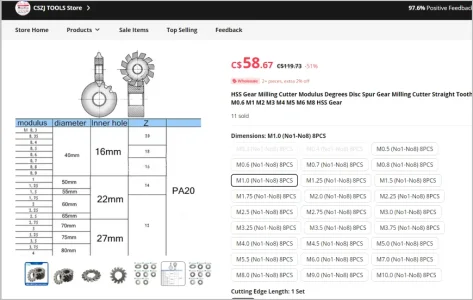

I also like Joe's version; I picked up these similar arbors (10mm/13mm/16mm) with a selection of Carbide saws on eBay back in the Summer:Interesting timing. Earlier tonite I went on a search for vids on the subject.

Joe Pie:

I kind of like Joe Pie's version.

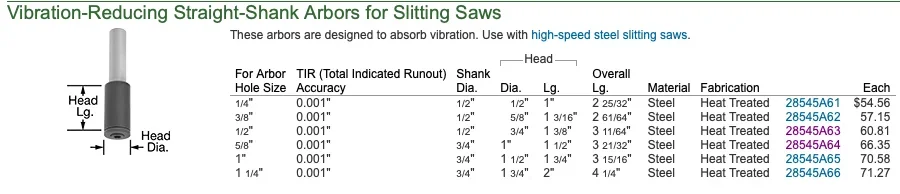

I also have this style of R8 arbor:

and these in 1/2" & 5/8":

However, these "Proudly Made in the USA" had more grit & dirt in them than anything I have purchased from China or India. They do perform well after being cleaned up, but I'm not convinced they are worth US$60+. Mine were US$51 & US$56 back in 2022; I emailed the manufacturer, but still haven't heard back from them (because of the quality issues, McMaster credited what I paid back to me; they're still selling them, so maybe the problem has been corrected?).

I bought some arbours from Ali but I don't like them.I also like Joe's version; I picked up these similar arbors (10mm/13mm/16mm) with a selection of Carbide saws on eBay back in the Summer:

View attachment 44988

If I could buy a blank R8 arbour (like you can buy machinable MT3 blanks) I'd prolly just make my own. In the meantime, the cheap Chinese Ali's seem to work, they just don't have the clearance I'd like.

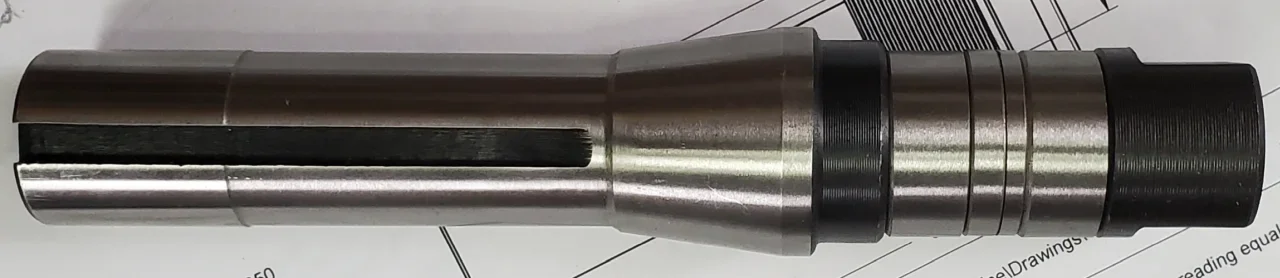

Some day I'll make my own with straight arbours like @ducdon did. I like the long shaft and the flat slender retainer.

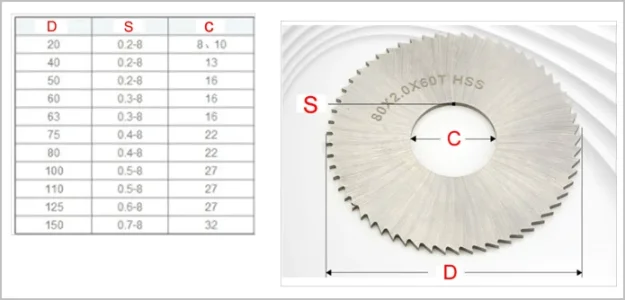

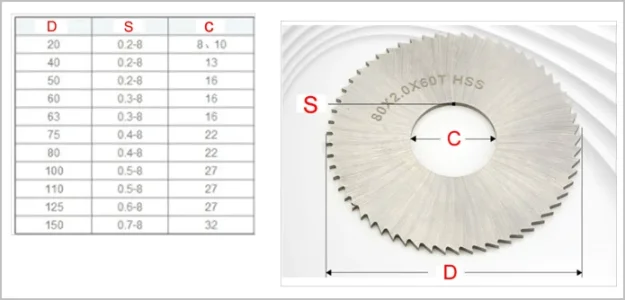

I had an Asian R8 with the nested rings style. Maybe they have since improved but mine was garbage. In reality, the rings didn't diametrically fit anything very well, metric or imperial saw ID's. And because there is cumulative tolerance, the saws never run true anyways. (Some people claim to semi tighten the saw & run slowly in reverse to improve centering before final tightening but that's a PITA). This was also the tool I discovered 'shallow out of spec R8 slot syndrome' & for a while mine was nested in my spindle set screw until I got it removed. Also the length between bottom R8 taper & saw is quite short so the quill can get in the way, at least for most parts I was faced with. Having a straight shank gives you more setup options & the sawing side loads aren't as high as say milling. Also the nominal R8 diameter is kind of a trade-of, too big for small saws (leaves small remaining saw depth) & too small for big saws (less flange support). That's why the arbors you see for commercial production come in a progressive range. However, this time round I bought progressive thickness saws but all in 100mm OD & they go down to 0.5mm or so. I just find them more useful in this diameter but you have to observe feed & chip clearing etc.

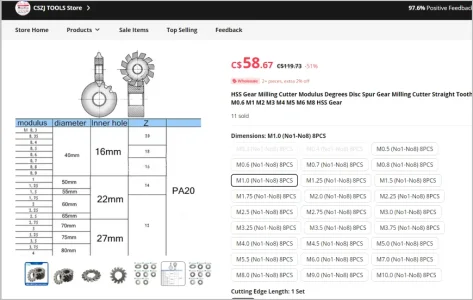

Is your slitting saw hole the same size as the gear cutter hole?Gear cutter arbor (and an uncommon taper?) but similar principle - demonstrates an extended shank section beyond the taper section.

View attachment 44996

In metric tooling, gear cutter hole ID's share same nominal hole diameters as saw ID's - 16, 22, 27 mm. Its been a while since I looked at IMP but it might be similar.

I tested & one of my gear cutters can be accommodated on one of my saw arbors. But gear cutters are thicker than most typical saws so its kind of at the limits of the saw arbor contact length. And none of the saw arbors I bought have a pin/key (nor do the saws which tells you something). So my conclusion is there could be some crossover at certain saw/gear sizes but generally gear cutter arbors might benefit from a dedicated arbor & that same arbor can be used for thicker/heavier load side milling cutters ?slotters? I bought an R8 gear cutter arbor on Ebay for ~70$ with the key & progressive collars etc. It is hardened, very accurate & well made so I'd be hard pressed to replicate that myself unless I wanted to just because.

I tested & one of my gear cutters can be accommodated on one of my saw arbors. But gear cutters are thicker than most typical saws so its kind of at the limits of the saw arbor contact length. And none of the saw arbors I bought have a pin/key (nor do the saws which tells you something). So my conclusion is there could be some crossover at certain saw/gear sizes but generally gear cutter arbors might benefit from a dedicated arbor & that same arbor can be used for thicker/heavier load side milling cutters ?slotters? I bought an R8 gear cutter arbor on Ebay for ~70$ with the key & progressive collars etc. It is hardened, very accurate & well made so I'd be hard pressed to replicate that myself unless I wanted to just because.

oh, reading this again, maybe I misunderstood your question. This was an internet picture, not my own. You can see the web address at very topIs your slitting saw hole the same size as the gear cutter hole?

@jcdammeyer if it is not too late could you make a video(s) of the ELS turning those threads?

No it's not too late. Be aware though that I don't have a power cross feed on the South Bend. Instead I set the compound at 29.5 degrees and tell the ELS to use the compound. Then it calculates the distance the compound has to travel for the thread depth (which can be calculated automatically from the pitch) and tells me how far to advance the compound.@jcdammeyer if it is not too late could you make a video(s) of the ELS turning those threads?

If I didn't have a compound like on the Unimat then I would disable use compound for threading and it would then give me the cross slide depth per pass.

Of course if it had a powered cross slide and use compound for threading is enabled it adjusts the cross slide and carriage position on each pass so the tool tip follows the 29.5 degree path (or 30 or 30.5) Or for ACME profile you disable compound for threading and it just plunges in at the same point.

When I get to it I'll set up the camera on the tripod and make a video. But will be kind of boring to watch me adjust the compound manually.

BTW. What started all this is the Busy Bee Tools kit I purchase more than a decade ago. Like this one from BusyBee but now they don't have the same keyed hole.In metric tooling, gear cutter hole ID's share same nominal hole diameters as saw ID's - 16, 22, 27 mm. Its been a while since I looked at IMP but it might be similar.

I tested & one of my gear cutters can be accommodated on one of my saw arbors. But gear cutters are thicker than most typical saws so its kind of at the limits of the saw arbor contact length. And none of the saw arbors I bought have a pin/key (nor do the saws which tells you something). So my conclusion is there could be some crossover at certain saw/gear sizes but generally gear cutter arbors might benefit from a dedicated arbor & that same arbor can be used for thicker/heavier load side milling cutters ?slotters? I bought an R8 gear cutter arbor on Ebay for ~70$ with the key & progressive collars etc. It is hardened, very accurate & well made so I'd be hard pressed to replicate that myself unless I wanted to just because.

View attachment 44998View attachment 45000

Buy Saw Slitting Arbor With 3pcs Cutter at Busy Bee Tools

B3115 Slitting Saw Arbor with 3 High Speed Steel Cutters This slitting arbor is hardened and ground offering the accuracy and durability required for hard slotting jobs. The shaft is long enough to be held securely in the collet and still provides sufficient tool access for cutting. The arbor...

www.busybeetools.com

www.busybeetools.com

What I do have for my gear cutters are 16mm and 22mm arbors like this:

So if I buy anymore replacement slitting saws I'll try to aim for ones that have 22mm holes and just use the existing R8 Arbor. For just 3 saws it's not worth going out and buying an off the shelf one with a 1" bore since I can make it myself. Plus kind of fun too.

Yes, I have a similar R8 (metric) gear cutter arbor. Seems like they make a longer & shorter version with the spacer rings & key slot. Yours looks to be the shorter version. But as mentioned I noticed few if any (metric) saws have the key slot so this arbor wont work unless you land it on the very end of the un-keyed portion which is probably not how its intended to be used. (And they have the big bejesus tightening nut on the bottom). Now there are also thicker kerf 'mill cutters' that do have/require a slot. I think that's kind of the duty range where saws ends & these cutters come into play.

Attachments

A dremel grinder can be used to create a key slot in the slitting saw. Not like it needs to be precise.

Interesting. I totally expected to find a key on the 16mm arbour. There isn't one even though the gear cutters are keyed. OTOH, the 22mm does have a key, as do the gear cutters but the key is removable. So slitting saws with a 22mm diameter will be on the shopping list once I need them.

Oh and also what is interesting is the thread pitch for the clamping nut is dramatically different for the non-keyed arbour. I'd have thought finer pitch could make for tighter grab on non-keyed items.

Oh and also what is interesting is the thread pitch for the clamping nut is dramatically different for the non-keyed arbour. I'd have thought finer pitch could make for tighter grab on non-keyed items.

Dan Dubeau

Ultra Member

I just ordered one of those 22mm ones to hold gear cutters. I was going to make one, but for $40 I decided I'd rather spend an extra hour at work, than a couple hours making one.

I made a long 1" shank slitting saw arbor years ago for a custom job at work. I had a cheap import I made an extension for but it broke before the job finished. Always planned on making a really nice one for general purpose but just ended up buying another import. I never learn.......Once of these days I might make a nice one.

I made a long 1" shank slitting saw arbor years ago for a custom job at work. I had a cheap import I made an extension for but it broke before the job finished. Always planned on making a really nice one for general purpose but just ended up buying another import. I never learn.......Once of these days I might make a nice one.

I've been busy sorting Misha's stuff and often just too tired or mentally weary to do much in the shop so it's been somewhat incremental.

The shaft is 0.75" (or so).

The shoulder is 0.875" which is supposed to be the peak of the 20 TPI thread. I also cut a slight groove to point out where the edge of the cutting tool is. I set my ELS END position to this point.

No picture but next I used the parting tool to cut runout groove to the depth of the thread. That didn't work out well because the parting tool was sloped downwards to the left so the left side of the slot wasn't as deep as the right side. Ah well.

I did start making a video. Did a nice first pass and then in the process of holding onto the camera trying to keep it aimed at the various items I pressed START without following the instructions on the screen to withdraw the tool. No matter. The first cut wasn't that deep so it didn't really affect the final product.

Anyway, made a much shorter one and now it shows just the final passes. Notice on the left the nut is held in place there for trial fittings. I had to take the part off the spindle drive after carefully scribing where it was and then putting it back.

But. No matter how many passes I couldn't get the nut to thread on.

So I pulled off the centers, installed the 4-jaw, centered the nut and then with a bit of difficulty got the ELS to line up the boring threading tool to line up with the threads. I then just kept going deeper testing with the now threaded arbor until it turned on smoothly.

And flush against the shoulder.

Next I need to turn it between centers again and cut the 1" diameter shoulder to register the blade and the nut.

Maybe tonight.

The shaft is 0.75" (or so).

The shoulder is 0.875" which is supposed to be the peak of the 20 TPI thread. I also cut a slight groove to point out where the edge of the cutting tool is. I set my ELS END position to this point.

No picture but next I used the parting tool to cut runout groove to the depth of the thread. That didn't work out well because the parting tool was sloped downwards to the left so the left side of the slot wasn't as deep as the right side. Ah well.

I did start making a video. Did a nice first pass and then in the process of holding onto the camera trying to keep it aimed at the various items I pressed START without following the instructions on the screen to withdraw the tool. No matter. The first cut wasn't that deep so it didn't really affect the final product.

Anyway, made a much shorter one and now it shows just the final passes. Notice on the left the nut is held in place there for trial fittings. I had to take the part off the spindle drive after carefully scribing where it was and then putting it back.

But. No matter how many passes I couldn't get the nut to thread on.

So I pulled off the centers, installed the 4-jaw, centered the nut and then with a bit of difficulty got the ELS to line up the boring threading tool to line up with the threads. I then just kept going deeper testing with the now threaded arbor until it turned on smoothly.

And flush against the shoulder.

Next I need to turn it between centers again and cut the 1" diameter shoulder to register the blade and the nut.

Maybe tonight.

There's a saying that the difference between an amateur and a professional is a professional knows how to cover up his mistakes.

With that in mind I think I'm starting to behave like a professional.

Still need to mill flats for the wrench. Last I checked the wobble between centers was less than 0.001". The saw is a sliding fit and once I cleaned up the tail end of the threads the nut pressed down perfectly.

Still need to custom grind a lathe tool to do a better undercut at the transition between the seating area and the flange.

The mistakes we'll talk about another time...

With that in mind I think I'm starting to behave like a professional.

Still need to mill flats for the wrench. Last I checked the wobble between centers was less than 0.001". The saw is a sliding fit and once I cleaned up the tail end of the threads the nut pressed down perfectly.

Still need to custom grind a lathe tool to do a better undercut at the transition between the seating area and the flange.

The mistakes we'll talk about another time...