Matt-Aburg

Ultra Member

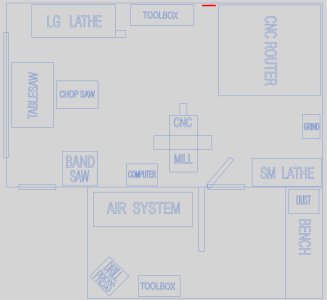

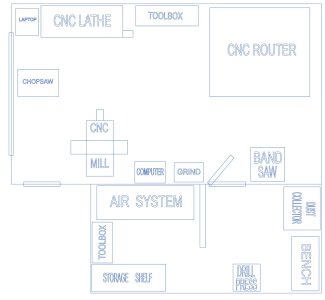

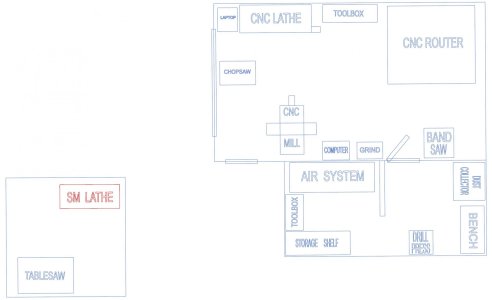

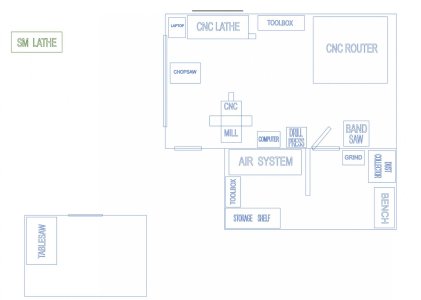

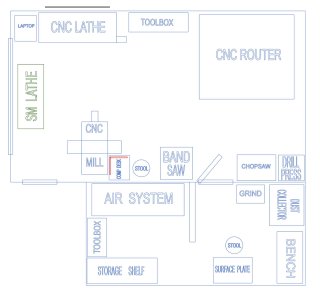

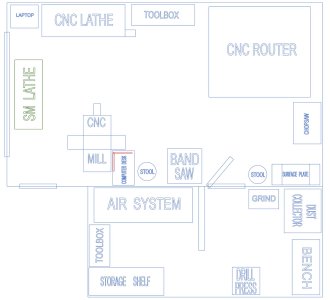

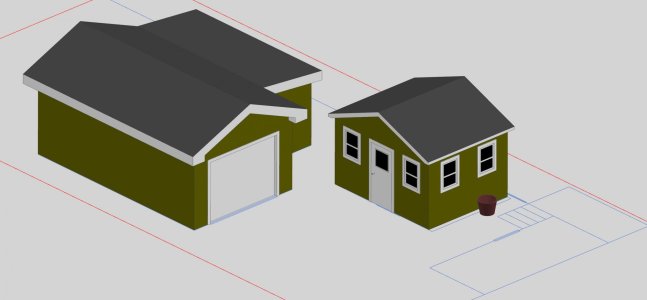

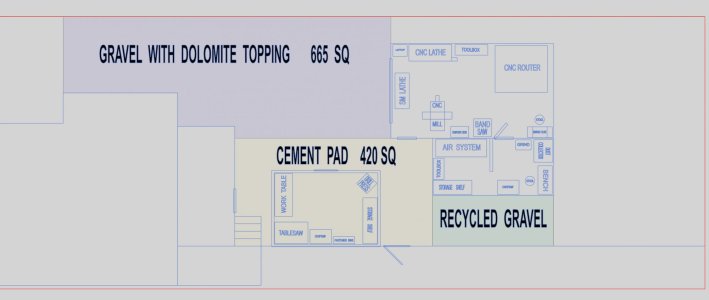

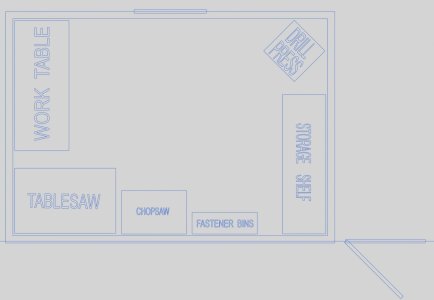

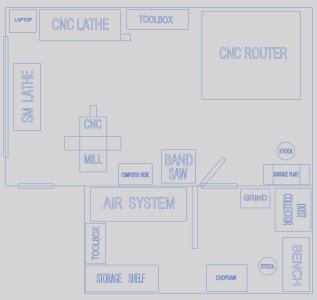

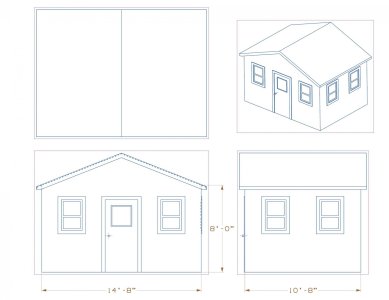

I have been renovating for the better part of 2 years now. I want to show where it is now (sort of). Where it is going, and the needed shed to free up space (in the spring. Note that both CNC Mill and CNC lathe are conventional machines with conversions done by CNC Masters out of sunny California. If I do end up going to a robust ATC Machining Center, I will be selling the Supra milling machine. The 1440 lathe is now active again. I will follow up with photos as we go... in time.