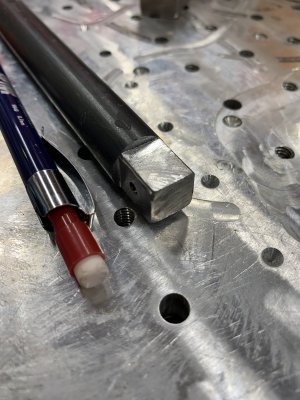

I saw this Rose Index tool on a video by Tubalcain. It was invented by and is made by Timm Rosenthal.

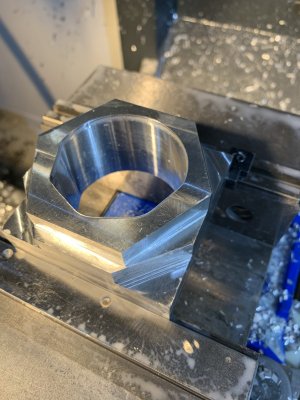

The Rose index lets you accurately rotate a part to specific angles in the mill without a rotary table or spin indexer. The idea is simple. Attach the indexer to your part and align the edge to a machinist square. Rotate to the desired angle, and align to the square again. Tighten vise and do the next operation. Could you use it in the lathe too? hmmm.

Pretty nifty concept. He has a patent too: https://patents.google.com/patent/US10850359B2/en?q=rosenthal&inventor=timm&oq=+timm+rosenthal

Store: https://rosenthalproducts.com/collections/all

He has different sizes and a fine adjustable version.

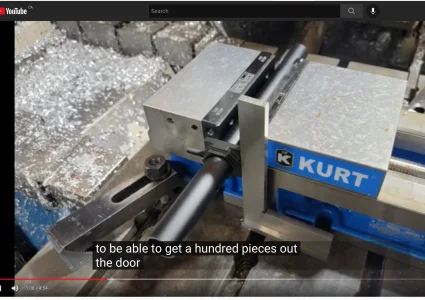

Here is tubalcain in action:

advance to 7:22 to see it.

The Rose index lets you accurately rotate a part to specific angles in the mill without a rotary table or spin indexer. The idea is simple. Attach the indexer to your part and align the edge to a machinist square. Rotate to the desired angle, and align to the square again. Tighten vise and do the next operation. Could you use it in the lathe too? hmmm.

Pretty nifty concept. He has a patent too: https://patents.google.com/patent/US10850359B2/en?q=rosenthal&inventor=timm&oq=+timm+rosenthal

Store: https://rosenthalproducts.com/collections/all

He has different sizes and a fine adjustable version.

Here is tubalcain in action: