-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rock Tumbler

- Thread starter jcdammeyer

- Start date

I expect that because it's not a Bambu filament ergo no RFID tag then that means you need to specify the print speed in the slicer.

Holy Crap! Filaments have RFID tags?

A friend of ours has taken up jewellery making and I remembered somewhere in my boxes of stuff I have an old rock tumbler that my mother used when she was into it. I found it, pulled it out and realized why we'd never done anything with it.

View attachment 57846Seems the drum that holds the rocks and abrasive was missing.

No problem. I have a 3D printer. A bit or research online and I found this one. A lid for each end. So it rides on the drive shaft on the outer part.

View attachment 57848 View attachment 57849

Didn't work well. Slipped with so little in contact with the long shaft. So I put some rubber around it. Better but as soon as I out rocks in it the drum just sat there.

So I designed my own.

View attachment 57851

Works much better but still slips a lot. Even after smoothing out the bumps from the 3D printing.

The problem is the drive shaft and idler are actually a steel shaft covered in a plastic tube. The plastic has hardened over time which isn't surprising given that it's likely 40 years old.

View attachment 57852

Looking for suggestions on what time of hose or tubing to use that would improve on what is currently there.

JCD, Well done.A friend of ours has taken up jewellery making and I remembered somewhere in my boxes of stuff I have an old rock tumbler that my mother used when she was into it. I found it, pulled it out and realized why we'd never done anything with it.

View attachment 57846Seems the drum that holds the rocks and abrasive was missing.

No problem. I have a 3D printer. A bit or research online and I found this one. A lid for each end. So it rides on the drive shaft on the outer part.

View attachment 57848 View attachment 57849

Didn't work well. Slipped with so little in contact with the long shaft. So I put some rubber around it. Better but as soon as I out rocks in it the drum just sat there.

So I designed my own.

View attachment 57851

Works much better but still slips a lot. Even after smoothing out the bumps from the 3D printing.

The problem is the drive shaft and idler are actually a steel shaft covered in a plastic tube. The plastic has hardened over time which isn't surprising given that it's likely 40 years old.

View attachment 57852

Looking for suggestions on what time of hose or tubing to use that would improve on what is currently there.

The drums are always missing when one finds these. They are expensive. I might be willing to buy several from you.

As far as the rubber part I just take a piece of black rubber hose and slip about an inch long on each end.

Doggggboy

Ultra Member

The Bambu filaments have RFID tags on the spools that are read by the AMS ( multiple spool holder thingy}. This way the printer knows which filament is in which position, what parameters to set the printer at for that particular filament, and how much filament is left on the roll. If you order a cheaper replacement roll of filament from Bambu, you just get a roll of filament that fits onto the original spool and another RFID tag to place on the spool.Holy Crap! Filaments have RFID tags?

And no, you are not locked into the Bambu ecosystem for filaments. They have presets for multiple filament brands as well as generic but Bambu is the only one that uses the RFID tags.

Last edited:

The Bambu filaments have RFID tags on the spools that are read by the AMS

Sounds both awesome and scary. Love the improvement and the plug N play aspect. But one more thing to know and remember and go wrong.

Doggggboy

Ultra Member

Anything can go wrong but this is one less thing to dick around with when you actually want to print something.Sounds both awesome and scary. Love the improvement and the plug N play aspect. But one more thing to know and remember and go wrong.

Tags of all types and sizes have become more common and are much cheaper/smaller.Holy Crap! Filaments have RFID tags

As an aside and rather off-topic comment (unrelated point of interest?): since the late 1970s, all commercial explosives manufacturers have been required to tag their explosive products using nanoparticles. Investigators can determine the source of an explosive used in a crime. In more recent years, these tags can be detected before the detonation, which helps to locate or detect explosive products.

Also (and even more unrelated) - using extremely sensitive vapor detection (smelling) airport security can detect if you have handled an explosive product within the last 3 months. Back when I was in the blasting business, (while traveling) I carried detailed documentation explaining my occupation and the legitimate reasons for handling explosives.

That's very sad... Is there like a support group for this?Hey Kids, Rocks???

Now we are in my wheel house!

I will talk about rocks as long as someone will stand in front if me!

Lol

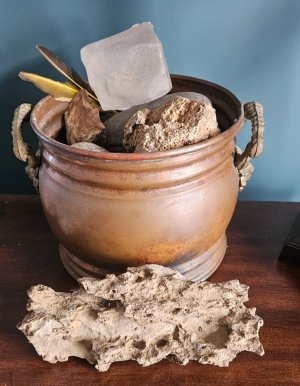

Heres a 10# Dunbar tumbler I purchased for $50 cleaned up and put in service.

I have several of those

I've only used the one Bambu filament and support filament that came with the printer. When I used up the green PLA that came with it I moved the RFID strip over to a different spool. It tells me it's green and a Bambu filament but prints fine.The Bambu filaments have RFID tags on the spools that are read by the AMS ( multiple spool holder thingy}. This way the printer knows which filament is in which position, what parameters to set the printer at for that particular filament, and how much filament is left on the roll. If you order a cheaper replacement roll of filament from Bambu, you just get a roll of filament that fits onto the original spool and another RFID tag to place on the spool.

And no, you are not locked into the Bambu ecosystem for filaments. They have presets for multiple filament brands as well as generic but Bambu is the only one that uses the RFID tags.

I think I'll order a few more of the more expensive Bambu filaments so I can score a few more of the RFID strips.

But Doggggboy is right. The Bambu RFID just makes things convenient. Any filament can be used. It's figuring how to set the parameters for a specific filament. But at $10 per spool cheaper it's worth the time.

I'm still working on the drums. The second is now leaking through the bottom. I think 15% fill isn't a good idea from a waterproof point of view.JCD, Well done.

The drums are always missing when one finds these. They are expensive. I might be willing to buy several from you.

As far as the rubber part I just take a piece of black rubber hose and slip about an inch long on each end.

I'm also still having trouble with the lid design. A third drum I printed with 100% fill has a terrible inner and outer wall texture and the new lid doesn't fit. The first one worked so well...

A word of warning to everyone that 3D printing can be very frustrating. Rewarding. But frustrating.

Kind of like metalworking as that milling tool bends in half or chips and leaves a rough surface. Or worse your probe runs at full speed into the side of the vise.

Kinda like AA.That's very sad... Is there like a support group for this?

Theres always a meeting somewhere..lol

I think Lortone was bought out by Covington. I did do a quick google search and tumblers and parts seem to be available.My wife has four little Loratone tumblers and an old large one. https://rocktumbler.com/ like his Model "B". Those drums are an industrial standard . We were given one and I made a tumbler for my rifle brass, copying and improving the old one . I had repaired and improved my wife's before so I had a pretty good idea. I used 1/2" heater hose on the shafts. I put identical pulleys on the two shafts so as to drive with both. The heater hose wears out, but is easily replaced. My tumbler works for an hour once in a blue moon, hers goes for months on end.

Loratone has gone out of business last year. Like many hands on hobbies, both the rock hounding and the lapidary are a dying hobbies.

My grandfather was mtce manager at the Silver Bell in Cobalt, the town where my mom was born. My father worked u/g at the 'Bell'. WWII made it a long-distance romance but they married when he returned from overseas. That sort of explains my rocky background and why I ended up a mining engineer. I too love rocks. I've literally got tons of 'special' rocks. My wife says I got rocks in my head. I was never bitten by the lapidary bug, even though my father had that disease.Hey Kids, Rocks

I'll send you a PM wmetfab with my coordinance. Maybe I could unload a few chunks of my dad's hoard.

PS - you may have noticed that my Forum avatar is a chunk of rock

Last edited:

Downwindtracker2

Ultra Member

We drove by Loratone's shop in Seattle one time, it wasn't very large. The equipment in her rock and gem club's workshop is mostly Loratone, as it was the inexpensive brand. Her club was founded in the late '60s, so the equipment was maybe 50 years old when I got to repair it. I have fixed every machine in there, and I'm not even a rockhound.

Covington is quality, as well as being good people to deal with. As I said those steel drums are sold by a number of firms. They have rubber liner, but they are still pretty noisy.

My wife tumbles rock for kids grab bags which are given out at their rock and gem show. A little bag of pretty rocks.

In January there is a large rock and gem show Quartzite Arizona which would bring rockhounds and sellers from all over. It was advertised as having 22 miles of tables. Think of taking your wife to a 22 mile long jewelry counter. I've bought used equipment there , which of course I have had to repair, for my wife's own shop.

Covington is quality, as well as being good people to deal with. As I said those steel drums are sold by a number of firms. They have rubber liner, but they are still pretty noisy.

My wife tumbles rock for kids grab bags which are given out at their rock and gem show. A little bag of pretty rocks.

In January there is a large rock and gem show Quartzite Arizona which would bring rockhounds and sellers from all over. It was advertised as having 22 miles of tables. Think of taking your wife to a 22 mile long jewelry counter. I've bought used equipment there , which of course I have had to repair, for my wife's own shop.

Wouldn't it be more like RLA?Kinda like AA.

Theres always a meeting somewhere..lol

One of my lines of collecting are ore samples. I have representative pieces from many mines in the NWT and Yukon all of them are now decomissionedMy grandfather was mtce manager at the Silver Bell in Cobalt, the town where my mom was born. My father worked u/g at the 'Bell'. WWII made it a long-distance romance but they married when he returned from overseas. That sort of explains my rocky background and why I ended up a mining engineer. I too love rocks. I've literally got tons of 'special' rocks. My wife says I got rocks in my head. I was never bitten by the lapidary bug, even though my father had that disease.

I'll send you a PM wmetfab with my coordinance. Maybe I could unload a few chunks of my dad's hoard.

PS - you may have noticed that my Forum avatar is a chunk of rock

This is a grab sample sawn off a float boulder from Cantex mine develpment, North Rackla project in the Yukon.

The project has higest grade of zinc lead silver ever found on the continent 22-24% Its also exceptionally rich in Germanium, so much so, they couldnt measure it.

CD had to evaluate 7 methods of measuring it till they customized a test that would work.

If any of you are interested here is a 11.5 min. video showing the project and the boulder the piece above got chopped off of.

The man who found this, his name is Charles Fipke, also the finder of a little project called Ekati diamond mine.

The project has higest grade of zinc lead silver ever found on the continent 22-24% Its also exceptionally rich in Germanium, so much so, they couldnt measure it.

CD had to evaluate 7 methods of measuring it till they customized a test that would work.

If any of you are interested here is a 11.5 min. video showing the project and the boulder the piece above got chopped off of.

The man who found this, his name is Charles Fipke, also the finder of a little project called Ekati diamond mine.

Attachments

Lortone recently suspended operations, they are no longer manufacturing machines.I think Lortone was bought out by Covington. I did do a quick google search and tumblers and parts seem to be available.

I have a 12" Covington flat lap with a set of diamond pads 60 to 3000 grit. Its used for hand polishing surfaces.

The Dunbar tumbler barrell is hexagonal shape and comes with a urethane liner inside

Now we are in my wheel house!

I will talk about rocks as long as someone will stand in front if me!

Lol

Hmmm..... @jcdammeyer is right. You need help. But it could be worse. Talking about them is one thing. Talking to them would be a much more serious concern......

My dad loved rocks too. And I inherited his love of rocks. I love them so much that I bought a rock farm where I grow them by the truck load. My rock farm straddles an old glacial moraine. The glacier pushed a massive moraine of rocks ahead of it rolling them along as it pushed south. It stopped right here and dumped them all as it melted.

This is a pile of selected rocks I hope to feature in an area of the basement - a bar or a fireplace.

These are landscaping size rocks ranging from fridge sized to bushel basket sized. They conspired to destroy my farm equipment so I had to pull them. I'll prolly make a big rock garden with them.

This is a typical year's worth of picking rocks. I traded 6 times this much for an equal volume of top soil.

It's amazing to see some of the rocks you find when you pick them by hand. A few have made it to my special collection in the front room.

I'm particularly drawn to rocks with included crystals, and to flint. I have this innate desire to take up flint knapping some day. I started regular napping a few years ago. It's amazing how good you can get at it with practice. I've even learned I can initiate a good napping session just by thinking about knapping! Its even easier if you stare at a chunk of flint long enough. Amazing stuff! Many have made it to window sills in the house and barn.

Even more have made it to rock gardens around the house. We keep those in themes. White with black speckles here, red over yonder, purple over there, etc. Most of these gardens are hidden under the snow right now, but a few are in direct sunlight.

That last one has some milkweed in it that we leave for the Monarch butterflies.

Another rock related thing I started ages ago was collecting a single rock on each trip I went on. I tried to find a rock that reminded me about the area itself and the adventure. So I have a rock from the purple rock cliffs along the Atlantic in Newfoundland, an ancient rock from the Alps around the Eagle's Nest in Germany, a wind eroded rock from the very top of Mount Fortress in Alberta - the only mountain I ever climbed. Child's play compared to @Tom Kitta's adventures. The one in from is the one from Alberta. The winds at the top of the mountain are fierce and sandblasted away the softer rock. It is beautiful in person.