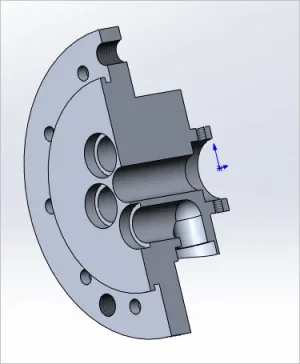

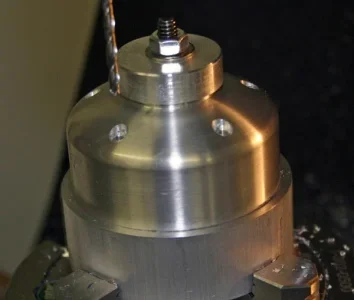

Finally! The cam plates are done. Made from A2 tool steel. Never worked with this stuff before. Its quite tough but light cuts & patience finished up OK. These need to be hardened so I've made contact with a local knife maker guy who has the appropriate equipment. Because the thinness & non-symmetrical shape & array of holes etc. I decided to try A (air) over O (oil) quenching tool steel. I figure with the work that went into them I just didn't want to add extra risk of 'potato chip' distortion if it were to hit a liquid quenched. So after heating in a stainless bag they get 'air' quenched but sandwiched between 2 aluminum plates. Then tempering to whatever temp to target hardness.

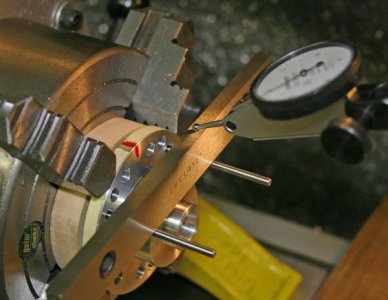

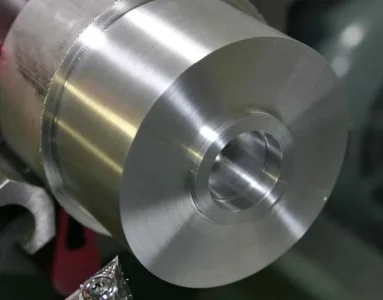

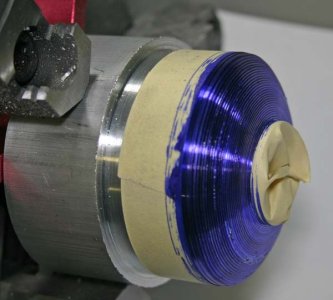

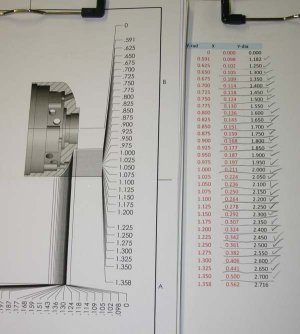

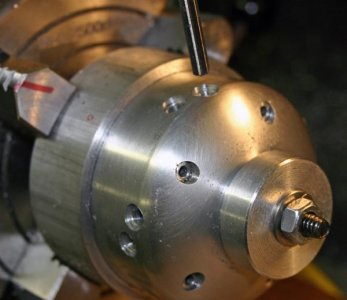

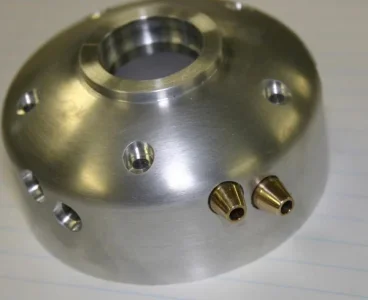

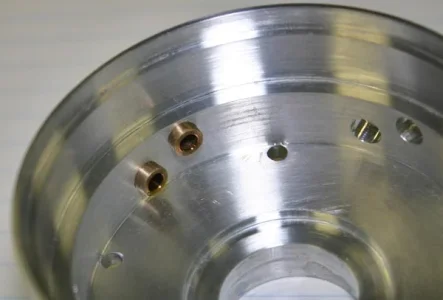

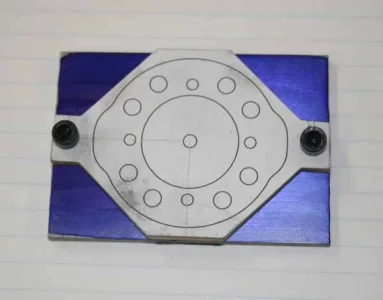

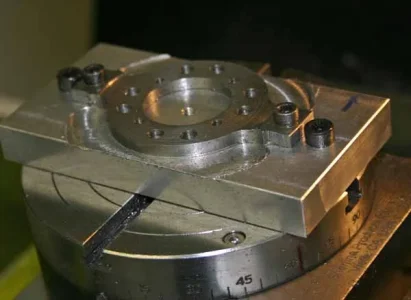

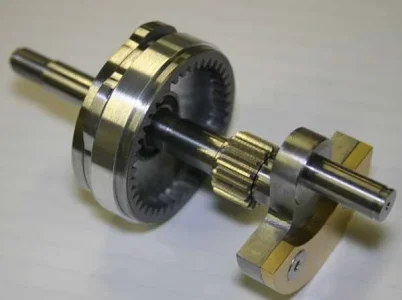

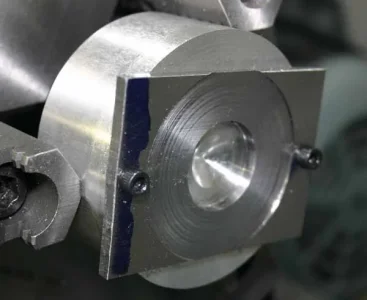

One lathe fixture was to hold the blank for center hole boring & reducing thickness to 3.5mm (metric plans) from IMP stock. Then part transferred to another mini rotary table fixture to mill the 2 (valve closed) radius arcs, then screw holes & lightening holes. One cam is intake, the other is exhaust, so the relative phasing once stacked comes about by orientation of M3 tap & clearance holes. So lots of RT angle positions to remember. Then I cut the ears off & utilized the holes to secure it to another lathe fixture for the OD (valve open) turning. Then some careful Dremel grinding to make a nice transition up the ramp of the lobe & polishing with rubberized abrasive.

I think I'm going to make these next so I can send them out together. Basically I want the followers to be a couple Rockwell points under the cam plates so the wear is on the easier to replace part. They are made from 4mm O1 round stock. They have a hemi-ball shape on the end that runs along these cam profiles. The other end is an internal (ball mill divot) here the rocker pushrods locates into.

One lathe fixture was to hold the blank for center hole boring & reducing thickness to 3.5mm (metric plans) from IMP stock. Then part transferred to another mini rotary table fixture to mill the 2 (valve closed) radius arcs, then screw holes & lightening holes. One cam is intake, the other is exhaust, so the relative phasing once stacked comes about by orientation of M3 tap & clearance holes. So lots of RT angle positions to remember. Then I cut the ears off & utilized the holes to secure it to another lathe fixture for the OD (valve open) turning. Then some careful Dremel grinding to make a nice transition up the ramp of the lobe & polishing with rubberized abrasive.

I think I'm going to make these next so I can send them out together. Basically I want the followers to be a couple Rockwell points under the cam plates so the wear is on the easier to replace part. They are made from 4mm O1 round stock. They have a hemi-ball shape on the end that runs along these cam profiles. The other end is an internal (ball mill divot) here the rocker pushrods locates into.

Attachments

-

IMG_6941_edited-1.webp19.7 KB · Views: 30

IMG_6941_edited-1.webp19.7 KB · Views: 30 -

IMG_6948_edited-1.webp16.9 KB · Views: 28

IMG_6948_edited-1.webp16.9 KB · Views: 28 -

IMG_6958_edited-1.webp25.4 KB · Views: 31

IMG_6958_edited-1.webp25.4 KB · Views: 31 -

IMG_6960_edited-1.webp14.6 KB · Views: 26

IMG_6960_edited-1.webp14.6 KB · Views: 26 -

IMG_6962_edited-1.webp20.1 KB · Views: 28

IMG_6962_edited-1.webp20.1 KB · Views: 28 -

IMG_6963_edited-1.webp15.7 KB · Views: 25

IMG_6963_edited-1.webp15.7 KB · Views: 25 -

IMG_6965_edited-1.jpg32.1 KB · Views: 26

IMG_6965_edited-1.jpg32.1 KB · Views: 26 -

IMG_6970_edited-1.webp14.9 KB · Views: 28

IMG_6970_edited-1.webp14.9 KB · Views: 28 -

IMG_6971_edited-1.webp15.6 KB · Views: 29

IMG_6971_edited-1.webp15.6 KB · Views: 29 -

IMG_6972_edited-1.webp17.1 KB · Views: 34

IMG_6972_edited-1.webp17.1 KB · Views: 34 -

IMG_6947_edited-1.webp23.2 KB · Views: 28

IMG_6947_edited-1.webp23.2 KB · Views: 28