Matt-Aburg

Ultra Member

This concept would be very easy to perfect... I need to hold large spools for an upcoming job. I would make proper sized cores to fit the spool.A bucket with a tight fitting lid and bunch of desiccant beads?

This concept would be very easy to perfect... I need to hold large spools for an upcoming job. I would make proper sized cores to fit the spool.A bucket with a tight fitting lid and bunch of desiccant beads?

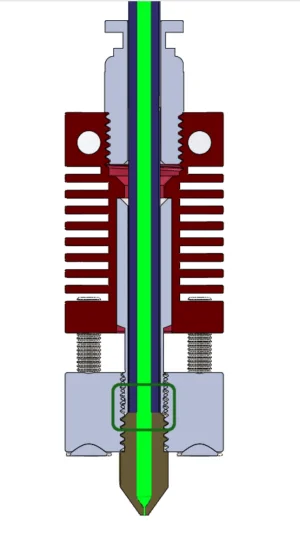

I don't have experience with Nylon, but just a quick comment on temperature. When I was hunting around for a printer 3 or so years ago I distinctly remember warnings about if your extruder has a PTFE liner, it will start off-gassing neurotoxins temps above 250C LOL.

I've heard popping when printing some filaments - it was not printing well. The popping is moisture exploding into steam? How are you drying your filament? There are some filament dryer appliances. I tried to use a toaster oven once on the above filament that was popping. I ruined the spool - all the filament melted all together.

I hope this is true for all printers currently on the market, but the ender 3 atleast (not sure about the ender 3 v2 or ender 3 Pro) had the PTFE tube go all the way through the heat break and butt up against the nozzle.afaik I the PTFE is on the other side of heat break and should never see temps like that.

I hope this is true for all printers currently on the market, but the ender 3 atleast (not sure about the ender 3 v2 or ender 3 Pro) had the PTFE tube go all the way through the heat break and butt up against the nozzle.

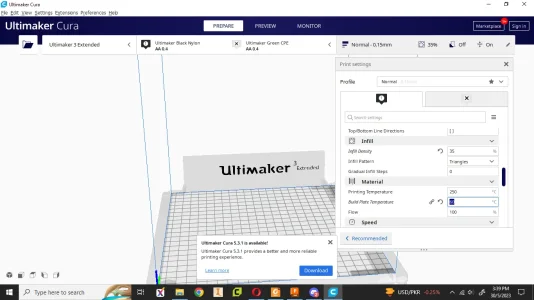

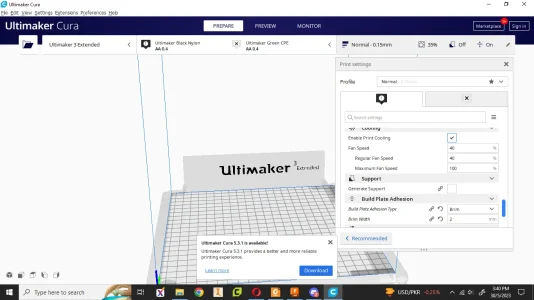

we have success with our ultimaker printers and nylon, what settings are you using to print?First off, I have had great success with PLA so far. Only one messed up print out of about 150 pieces because I didn't have the bed leveled quite right.

however, I warned you I'd be a pain the butt with questions so here goes.

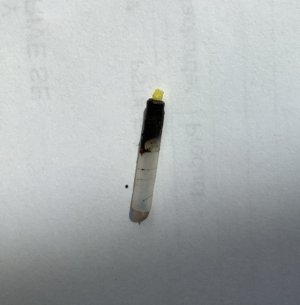

I purchased a roll of nylon filament and wanted to print a couple things and have had nothing but failure and frustration. I have spent several hours on google and youtube trying to figure this out with no success. I cannot get the prints to adhere to the bed, and have had to unplug and clean out the nozzle several times (glad I have an extra one)

Here's what I've tried so far:

-gone through all the slicer settings (I'm using Cura 4.5) and tried many different combinations of temperature and fan settings as per several suggestions on the 'net

-installed a glass bed with glue stick and retried the different settings.

If anyone has suggestions that could help me sort this and figure out what I'm missing would be awesome.

BTW...It was a brand new sealed package so I don't think I need to "bake" it and dry it out, or do I?