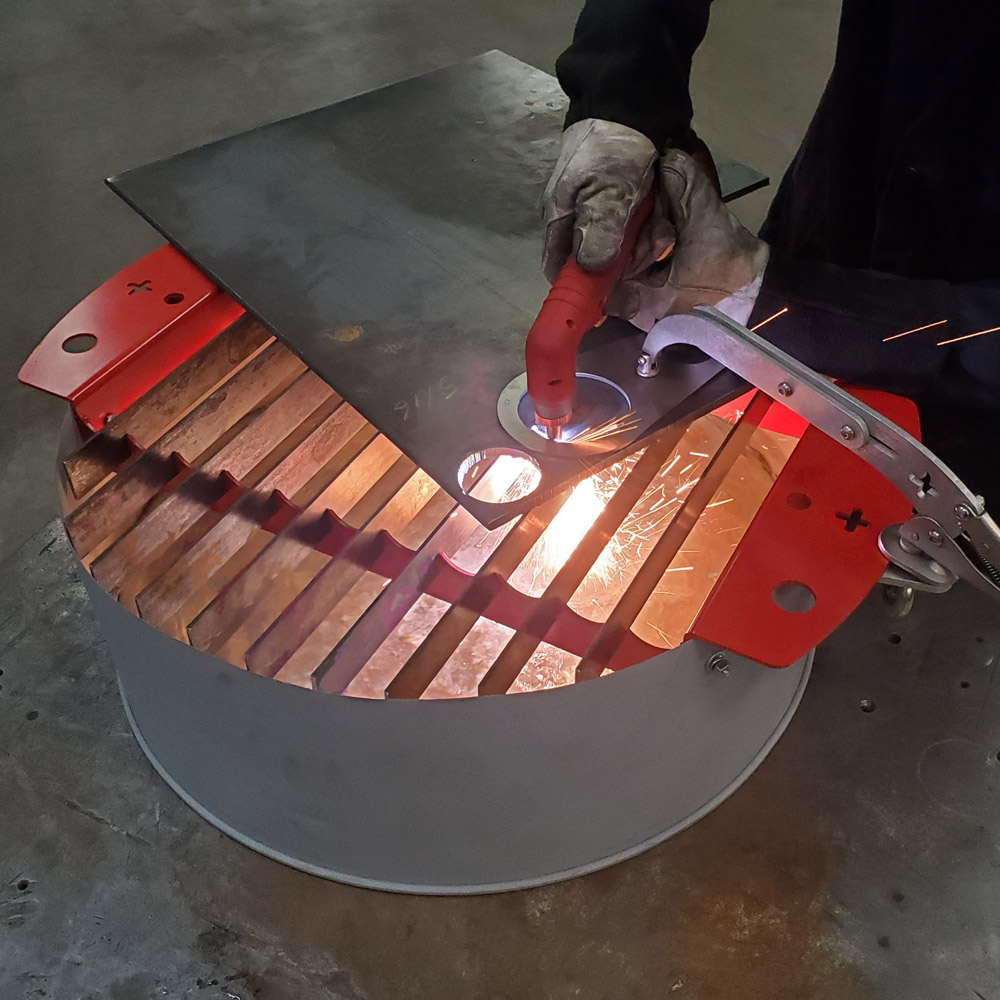

No I made it - but 911 sells a pre-cut kit that you weld together. I copied their idea from pictures on their web site. I made enough modifications that I don’t think they will send blood thirsty lawyers looking for a 25% Trump tariff for copy rights infringement.from 911 Motorsport?

Which reminds me that I should have included a link. Even our one-eyed-hairy-farmer could stick it together:

Round Tub - Plasma Table Kit for 55 gal. drum or 17 gal. tub

www.911motorsports.net