KeeponDragon

no problems... just challenges

**makes mental note to pull the covers off the WarFox cutter next time in the shop**

The other thing I'd suggest to do once these units are unboxed...is take whatever the manufacturer is trying to pass of as "pnuematic connections" and toss em in the scrap bin.

They are without doubt...utter garbage...NPT must mean Not Possible Ted in Asia...

The threads were about 1/2 of the required depth, and definitely not tapered...

The air regulator, on the otherhand, that came with my WarFox50 from Amazon...is a great part...it got installed...

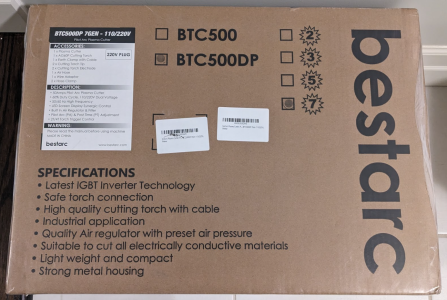

It's a great machine for me overall. Cuts steel and aluminum, maybe other materials but I haven't tried.

AND I like the fact it can run on both 110 and 220.

So it sits next to my Pro Point 3 in 1 welder on the cart.

The other thing I'd suggest to do once these units are unboxed...is take whatever the manufacturer is trying to pass of as "pnuematic connections" and toss em in the scrap bin.

They are without doubt...utter garbage...NPT must mean Not Possible Ted in Asia...

The threads were about 1/2 of the required depth, and definitely not tapered...

The air regulator, on the otherhand, that came with my WarFox50 from Amazon...is a great part...it got installed...

It's a great machine for me overall. Cuts steel and aluminum, maybe other materials but I haven't tried.

AND I like the fact it can run on both 110 and 220.

So it sits next to my Pro Point 3 in 1 welder on the cart.