No vibration. We have the gullets in the tap that separate the teeth. The length of the teeth is fairly short, so yes there is a small helix angle and there probably is a little binding during the cut, but I didn't have any issues. Look at a thread milling cutter, its like I have 6 of them cutting at the same time.Each row of teeth will be offset from the previous row by the thread pitch divided by the number of flutes.

What I want to know is how he stops it from vibrating like crazy as each flute tries to climb its own cut!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ontario Meet and Greet May 28th at BrentH's place

- Thread starter Brent H

- Start date

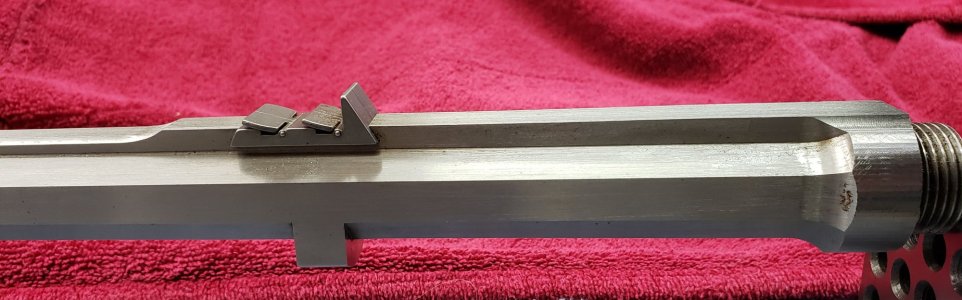

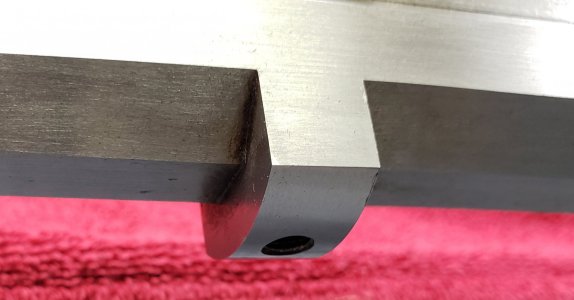

The barrel started out as a 2" chrome-moly round blank from Krieger Barrels. .458 caliber. Full octagon, with integral full length sculpted rib, integral recoil shoulder, integral sling swivel projection, integral front sight ramp which accommodates a flip up express night sight. The only parts that are removeable are the rear express sight and front sight.Tell me more about this Barrel, it appears to have a set of "express" sights incorporated into its design.

Attachments

-

20220601_150732.jpg249.1 KB · Views: 25

20220601_150732.jpg249.1 KB · Views: 25 -

20220601_150629.jpg157.7 KB · Views: 22

20220601_150629.jpg157.7 KB · Views: 22 -

20220601_150553.jpg207.6 KB · Views: 31

20220601_150553.jpg207.6 KB · Views: 31 -

20220601_150528.jpg187.6 KB · Views: 28

20220601_150528.jpg187.6 KB · Views: 28 -

20220601_150416.jpg193.1 KB · Views: 29

20220601_150416.jpg193.1 KB · Views: 29 -

20220601_150344.jpg195.2 KB · Views: 31

20220601_150344.jpg195.2 KB · Views: 31 -

20220601_150211.jpg449.1 KB · Views: 28

20220601_150211.jpg449.1 KB · Views: 28 -

20220601_150436.jpg249.1 KB · Views: 26

20220601_150436.jpg249.1 KB · Views: 26 -

20220601_150144.jpg614.3 KB · Views: 31

20220601_150144.jpg614.3 KB · Views: 31

No vibration. We have the gullets in the tap that separate the teeth. The length of the teeth is fairly short, so yes there is a small helix angle and there probably is a little binding during the cut, but I didn't have any issues. Look at a thread milling cutter, its like I have 6 of them cutting at the same time.

I see.

I missed two factors in my assessment.

There are 6 flute, not four. And it's a 1" Tap not a small 3/8 or 1/4.

Because of these two factors, there is very little actual advance along the thread per tooth. So not much to worry about in terms of pulling the tap along the thread Helix. I think a smaller tap would not be as forgiving.

Cool idea!

This forum is using up a lot of my spare time. I keep running across interesting ideas.Hi Peter, the tap has not been modified. Its a little difficult for me to explain properly, but here goes. Think of making a thread on the lathe of 16tpi. So in one inch we've cut 16 threads. Now if we attach another tool post directly behind with another threading tool, and advance them at the same time, we're cutting another groove 180° to the first thread. So now in one inch we have 2x16 threads=32 threads, if you had 6 cutters starting to cut a shaft all equally placed around, then you have 6 x 16 threads=96 threads in one inch. Its the same idea as multi start threads. Did I make that more confusing?

So.

A chunk of 1/2" aluminum plate from my scrap bin, and a truly horrible and dull 4-flute 3/8'-24 UNF tap from a $12 Canadian Tire tap and die set. No coolant. No measuring and the plate isn't set true to the quill. No effort spent in trying to make it pretty, just chucked the tap into my mill (using a drill chuck), and scrubbed it across the plate a couple of times at 500 rpm, 0.010" depth of cut per pass. Lots of tearout, the tap wouldn't cut butter.

My ancient eyeballs and a 32 TPI thread gauge says 96 LPI is about right.

This could be an interesting surface finishing method.

Well done. You'll get a better effect in steel or high strength aluminum like 7075. Aluminium is generally gummy and won't work as nice.This forum is using up a lot of my spare time. I keep running across interesting ideas.

So.

A chunk of 1/2" aluminum plate from my scrap bin, and a truly horrible and dull 4-flute 3/8'-24 UNF tap from a $12 Canadian Tire tap and die set. No coolant. No measuring and the plate isn't set true to the quill. No effort spent in trying to make it pretty, just chucked the tap into my mill (using a drill chuck), and scrubbed it across the plate a couple of times at 500 rpm, 0.010" depth of cut per pass. Lots of tearout, the tap wouldn't cut butter.

My ancient eyeballs and a 32 TPI thread gauge says 96 LPI is about right.

This could be an interesting surface finishing method.

View attachment 24260

View attachment 24259

historicalarms

Ultra Member

The barrel started out as a 2" chrome-moly round blank from Krieger Barrels. .458 caliber. Full octagon, with integral full length sculpted rib, integral recoil shoulder, integral sling swivel projection, integral front sight ramp which accommodates a flip up express night sight. The only parts that are removeable are the rear express sight and front sight.

Wow that is awesome work man. Stand and be acknowledged by a complete amateur that dabbles in the same pool...is that sling anchor inletted into the barrel or free cut in the blank?

Is that threaded for a Highwall or some Sharps action or one of the modern offerings of a single shot action??...Oh ya and Chambering??

Now the "practical" side of me comes out...how come for the huge sight elevation difference between the steel ball and the flip-up Ivory ball. That much difference could be made use of with a Vernier rear sight but with the express sights they will have at least a foot POI change at even a close 100 yrds.

Thanks for the kind words @historicalarmsWow that is awesome work man. Stand and be acknowledged by a complete amateur that dabbles in the same pool...is that sling anchor inletted into the barrel or free cut in the blank?

Is that threaded for a Highwall or some Sharps action or one of the modern offerings of a single shot action??...Oh ya and Chambering??

Now the "practical" side of me comes out...how come for the huge sight elevation difference between the steel ball and the flip-up Ivory ball. That much difference could be made use of with a Vernier rear sight but with the express sights they will have at least a foot POI change at even a close 100 yrds.

The sling swivel stud is integral with the barrel. The barrel is for a custom Magnum Mauser. Caliber is 450Rigby. The ivory flip up bead accurate to minute- of-elephant...if you know what I mean.

historicalarms

Ultra Member

yup...at 30 ft that sight difference will make very little difference 🙂Thanks for the kind words @historicalarms

The sling swivel stud is integral with the barrel. The barrel is for a custom Magnum Mauser. Caliber is 450Rigby. The ivory flip up bead accurate to minute- of-elephant...if you know what I mean.