the DRO was from selling other shop tools I don't need

I don't think the last two items on your Ali list are compatible with each other. Were you planning to use them independently? Lots of us have made quill scale mounts to adapt a suitable scale to our mills.

When I did mine, I even configured my dro to add the two Z components - table and quill so I get one Z readout on my DRO.

I started this thread somewhat in frustration at not being able to find detailed instructions on how to install magnetic scales on my Hartford Clone. So it will be a long thread asking lots of questions and dealing with lots of challenges.

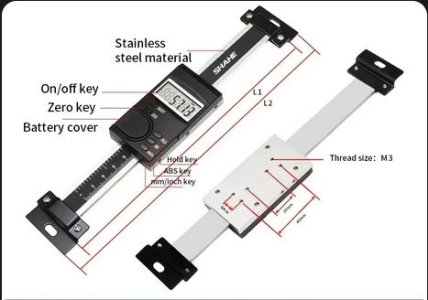

The DRO is a Ditron D80 with Slim 1micron Magnetic Scales.

I will also include a few posts about how I mounted the display and probably add additional posts as I change things in future. Thanks in advance to everyone who will contribute.

The DRO is a Ditron D80 with Slim 1micron Magnetic Scales.

I will also include a few posts about how I mounted the display and probably add additional posts as I change things in future. Thanks in advance to everyone who will contribute.

- Susquatch

- Replies: 153

- Forum: Machine Talks. Mills, Lathes, Shapers, etc.

It's a long read to get to the quill install but hopefully worth the time for you.