Tomc938

Ultra Member

I see tons! Amazing results on rust removal.You no see pics? Anyone else? I see them... Too many in one post?

I see tons! Amazing results on rust removal.You no see pics? Anyone else? I see them... Too many in one post?

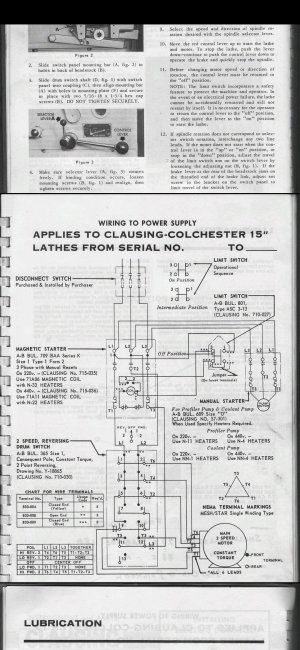

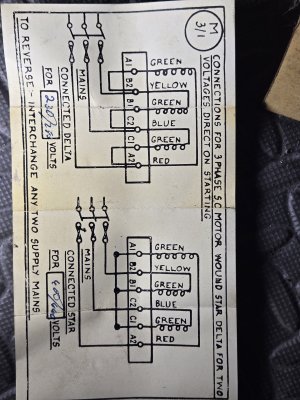

And lastly I had a look at the electrical. Ok first I give you exhibit A which led me to believe it was setup for 440v.

View attachment 54046

Very good lets have a look at the motor

View attachment 54047

Alright lets crack the wiring box. Oh look a little envelope

View attachment 54048View attachment 54049

Yes, yes,

View attachment 54050

What is this?! There are B1-C2,A1-B2, and C1-A2 jumpers, which tells me it was wired for 220v! I thought it was common courtesy to update the machine plate with a voltage change. But I believe this means the contactor should be good to go and i need only apply 3phase 220v to run it. Can someone confirm this? Either way I think Ill try it tomorrow.

I did have a peek at the contactor

View attachment 54052View attachment 54053

Im debating on whether or not to flush the headstock and or run it for a bit with diesel...

kerosene worked great in grinder spindle so +1I agree with Susq - not diesel (it won’t destroy it or anything). The prescribed lube is never a bad thing. I have also used kerosene flush for cleaning gear boxes - both to flush and blasting around all the non-wetted surfaces (easy to get, not expensive, goes through the solvent sprayer better than lube oil). That was on the Huron main gear box that had some sort of black coating throughout (you gearbox looks relatively good).

The thread dial is completely seized patiently waiting to be looked at. Good point with the magnet, Ill do that.It's cleaning up well. Have you got to the threading dial yet? It sure looked ugly in the pic.

Have you searched the bottom of the headstock with a magnet to see if anything is there that shouldn't be?

Now you have me paranoid about particles. I was about to send it with the old oil for a bit, it looked not terrible, but getting right in there with an eyeball there was small particles in there, so Ill drain and flush a bit before new oil before I run it. Ya I got iso32 on tap.The unspoken thing about heastocks that share oil with the bearings is clean, clean, clean. Clean out any junk and old oil so you could eat off the insides. Then add lube. it can be anything cheap. If you go kerosene, then i agree to not rotate the bearings with kerosene. The reason is that there will be microparticles suspended in the oil in the bearings. as you dilute this oil, they are no longer suspended in the oil, and will cling to the bearing surfaces. This makes them harder to rinse out, not easier. There are too many nooks and crannies for the particles to cling to.

however - it is a great idea to flush the gears with varsol, naptha, or diesel. this, along with a tooth brush, can help free any deposited crud on the faces and teeth of the gears. It just isn't so good for the bearings, with all the hidden corners.

I try to use a similar viscosity to what is there to flush a headstock. After installing a bunch of cheap magnets in the bottom pan, I add new oil and run it with no chuck (no load) for a little bit, and check the oil. If there are particles clinging to the magnets, then careful monitoring is needed to get the bearings completely clean. (usually another flush with oil) I always use clear ISO 32 hydraulic oil, so it is easy to spot the build up. (and it is cheap-ish)

I hope this helps.

I went to the big city and grabbed some 10/4 getting ready to get back to putting a plug on and running it, but it has me wondering what is going on - did someone half ass a voltage change? Is the contactor for 220 or 440? Theres not much for markings on the contactor - can a guy check the resistance to see which heaters it has?

I went to the big city and grabbed some 10/4 getting ready to get back to putting a plug on and running it, but it has me wondering what is going on - did someone half ass a voltage change? Is the contactor for 220 or 440? Theres not much for markings on the contactor - can a guy check the resistance to see which heaters it has?