-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New thread 3D Printing

- Thread starter Janger

- Start date

Bofobo

M,Mizera(BOFOBO)

Im positive that this is a cross over medium, cnc steel printers are already using the same tech, built on a foundation of cnc programing widely used in metal fabrication and cnc machines. If i can get a grasp of the tech i would build a fluxcore printer, because why not!?

You could but there is way more 3D printers out there I’m just wondering if the site would be overwhelmed and steered off course!

But as a prototyping medium, Gcode tutor etc it is an indispensable part of my shop now. If I can only get time to perform some lost wax casting...........

Sent from my iPhone using Tapatalk

Here is my ford boy making a really fancy aluminium part by casting from 3D printed lost wax process. Pretty neat stuff. My spouse was asking why did he need to fool around with all that piping through the sand. Why not just fill up the mold with aluminium to the top? I mean just fill the white investment cast mold?

Tom O

Ultra Member

I tried using some plaster and sand for a casting once after drying in the kiln they become quite brittle. I used a printed mold and that microwaveable material from PMS Hobbies you just heat it and pour giving you a rubbery pattern although it is flexible but could be strengthened with wire in the cavity or cooled in the fridge.

Tom O

Ultra Member

Are we talking about using the centrifuge type of casting? I have been toying with the idea of building one for my Sons wife and Daughter.But as a prototyping medium, Gcode tutor etc it is an indispensable part of my shop now. If I can only get time to perform some lost wax casting...........

Sent from my iPhone using Tapatalk

3D printed casting sand. Now we're talking. Eliminate the plastic/wax middleman.

I should send in a CAD file to get a finished aluminum all-in cost guestimate. Anybody heard of this technology?

http://www.fastcastings.com/sand-casting/

I should send in a CAD file to get a finished aluminum all-in cost guestimate. Anybody heard of this technology?

http://www.fastcastings.com/sand-casting/

Attachments

DianaPowell

Member

Can anyone show their creations on a 3D printer

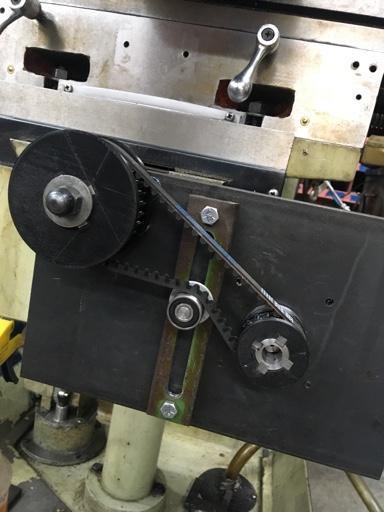

I mostly print parts as models for sand casting but have also replaced parts on my equipment including the pulleys on my cnc mill

Sent from my iPhone using Tapatalk

42 hours. Allot of time was spent printing the supports that were needed for the top. I think I could have printed it upside-down and saved 10 hours but then it wouldn't look as nice from the front.How long did it take to print that?

Tom Kitta

Ultra Member

So since I have lots of people that have printers is this is a good thread to ask for suggestions about a FDM printer purchase? I was thinking about more basic model up to say $500 but fully functional, not a kit, just something that will do some prototyping and look decent. There seems to be a lot of choices - is there a trustworthy site comparing the models?

My research of resin vs. FDM show that resin is around 3x more expensive to run then FDM but in the same printer class produces a bit better resolution. Through the main "shine" area is use of resin that is "special" - for example - one that is resistant to heat.

My research of resin vs. FDM show that resin is around 3x more expensive to run then FDM but in the same printer class produces a bit better resolution. Through the main "shine" area is use of resin that is "special" - for example - one that is resistant to heat.