Honestly, I am not overly worried about it. Now that I know what is going on, it is easy to deal with....but, due to the response here, maybe I should be more concerned.

I will take another look at it. I don't want to void my warranty messing with something that is like a manual transmission,,,you can find the wrong gear if looking for it. Having said that, it would be nice to just throw the lever into position. I am giving my self time to get used to it...maybe it is my small but generally ham fisted actions causing the issue...

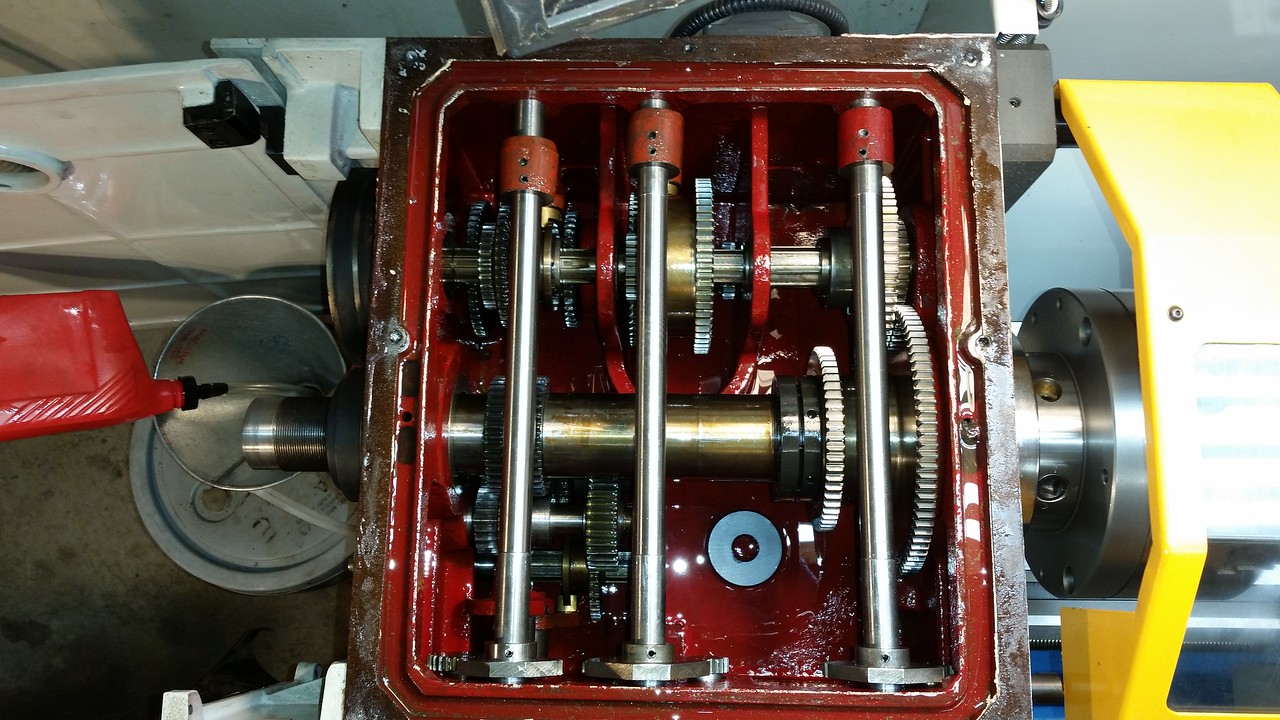

Here is the photo. As shown, the arrow points to the feed gear. In the photo, it is in the correct position for a right direction feed, and this position does have a corresponding "endent?" where it should be. However, when moving it, cause things are still tight, I suspect, it is easy to overshoot this position and move the gear more to the right, causing the noise in the video. The same distance is not attainable when going in the other direction cause the gear is limited by the wall of the gearbox.

I will compare what is there to what the parts diagram shows.